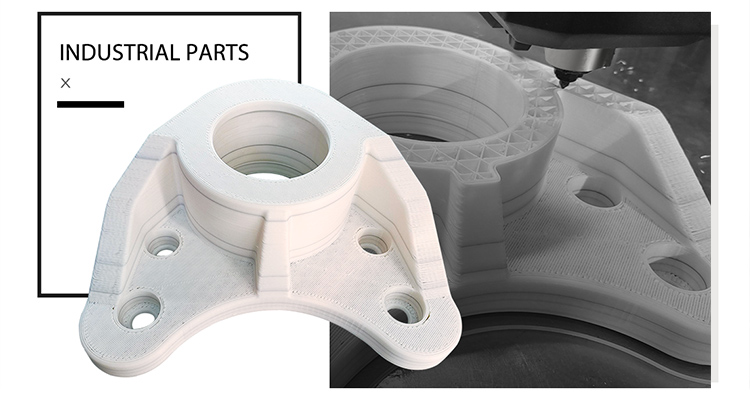

Additive manufacturing or 3D printing is a method of creating objects that can provide new possibilities for the design of parts with complex geometries-these designs are beyond the capabilities of traditional processes such as machining, casting, and molding. As the name implies, additive manufacturing creates objects by adding materials layer by layer (the most common are polymers and metals, but also concrete and drugs). In addition to final part production, 3D printing is particularly useful for rapid prototyping and processing.

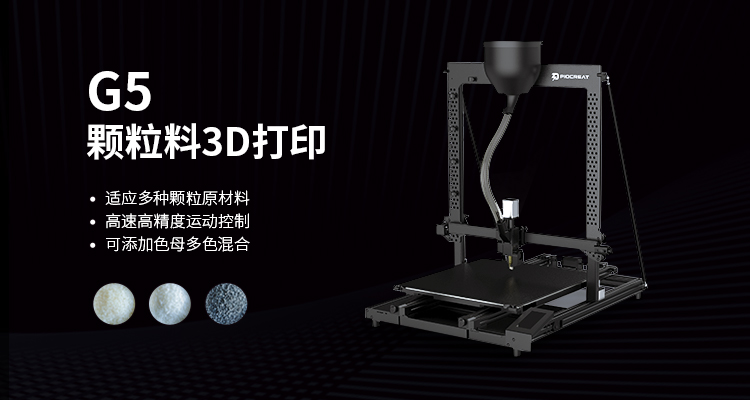

There are a variety of 3D printing technologies, including fused filament manufacturing and fused pellet manufacturing (sometimes called "particle printing".)

For FGF printing, thermoplastic pellets are heated in a barrel and screw extrusion system, and then deposited through nozzles to print the layers of the part.

Raw materials-filaments and

pellets 3D printed thermoplastics all start from pellets. FFF material is made by heating particles and forming them into filaments. FGF pellets skip this step-fewer heating cycles may mean pellet thermoplastics will be easier to process, perform better, and cost less than similar filaments.

Throughput — 3D printing throughput is measured by the flow rate of extruded thermoplastic. Throughput is usually measured in grams per kilogram or pounds per hour. The small heating zone of FFF printers limits its throughput. Typical throughput ranges from 2.27 g/hr to 113 g/hr (0.005 lb/hr to 0.25 lb/hr). On the other hand, FGF printers are limited by the size of the extruder and screw design, with typical throughput ranging from 227 g/hr to 9 kg/hr (0.50 lb/hr to 20 lb/hr).

Resolution — 3D printing resolution refers to the height of the layer and the width of its beads. For FFF printing, filaments and small nozzles mean higher resolution. Typical layer heights range from 0.15 mm (0.006 inches) to 0.4 mm (0.016 inches), and weld widths range from 0.3 mm (0.12 inches) to 1.00 mm (0.04 inches). It is worth noting that FGF printing has a lower resolution, the typical layer height ranges from 1 mm (0.04 inches) to 5 mm (0.2 inches), and the bead width ranges from 2 mm (0.08 inches) to 10 mm (0.4 inches). .

Printing complexity-due to its smaller nozzle and bead width, FFF printing allows more detailed parts and complex features. On the contrary, due to FGF's lower resolution and wider extrusion path, FGF printed parts have fewer features and lower complexity.

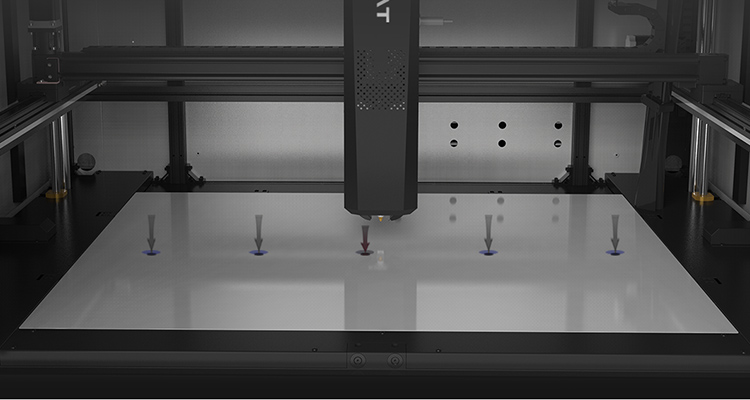

Tool path-For these two types of 3D printing, the programmed path of the extruder is called the "tool path". FFF printing allows for the construction of complex paths for complex parts-however, care must be taken to limit excessive motion, as this will reduce production. The tool path printed by FGF is simpler, but more attention needs to be paid to the part design and printing direction to avoid the tool path crossing itself.

Processing temperature-Keeping the material temperature just right is essential for successful additive manufacturing. For these two technologies, a controlled and consistent temperature needs to be maintained throughout the printer throughout the process. Interlayer adhesion is crucial-this is the biggest weakness in material extrusion printing-so it is very important to ensure that the deposited material adheres well to subsequent layers. Using a controlled and heated chamber, the operator can prevent the part from cooling too fast-this increases the strength of the printed part in the z direction. The heated build chamber ensures adequate bonding, reduces warpage, and ultimately helps ensure accurate part dimensions.

For filament printing, the goal is to get more heat into the material to print faster, and keep each layer at the same temperature as the previous layer. On the other hand, due to the printing speed and the amount of thermal energy deposited on each layer, particle printing may require cooling, which can cause the layers to sag-leading to poor quality or printing failure.

Nozzle size for FGF printing — part design, 3D printing material and surface appearance will all affect the nozzle size used. The use of highly filled, high-viscosity materials usually means that the FGF nozzle size is smaller.

FFF and FGF polymer materials

FFF and FGF polymer materials

The thermoplastic materials used for the manufacture of melted filaments and melted pellets are based on nylon, polyester or polypropylene chemicals. As manufacturers use 3D printing technology for functionality and end use