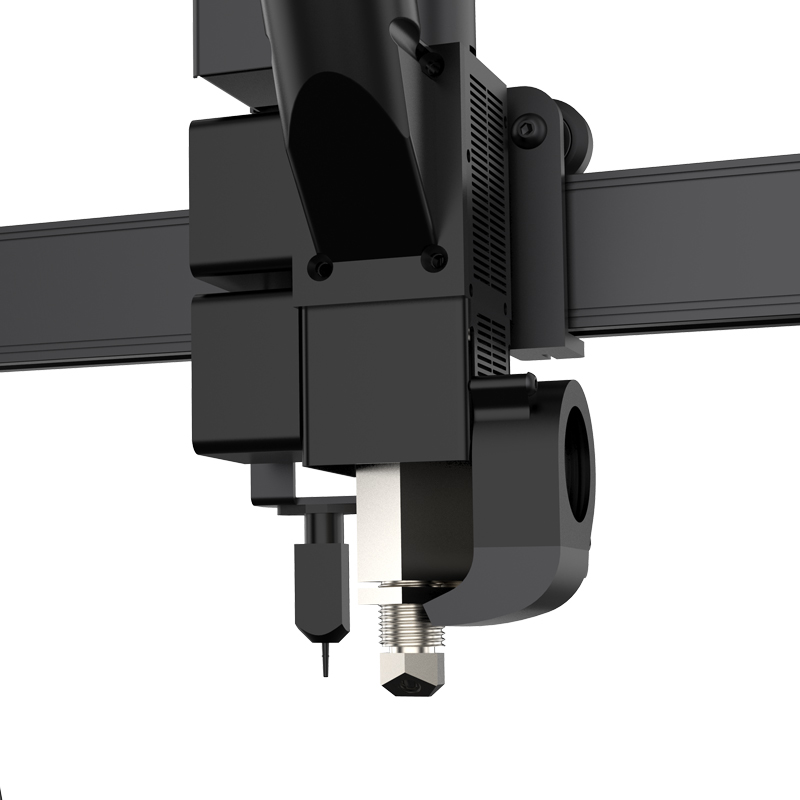

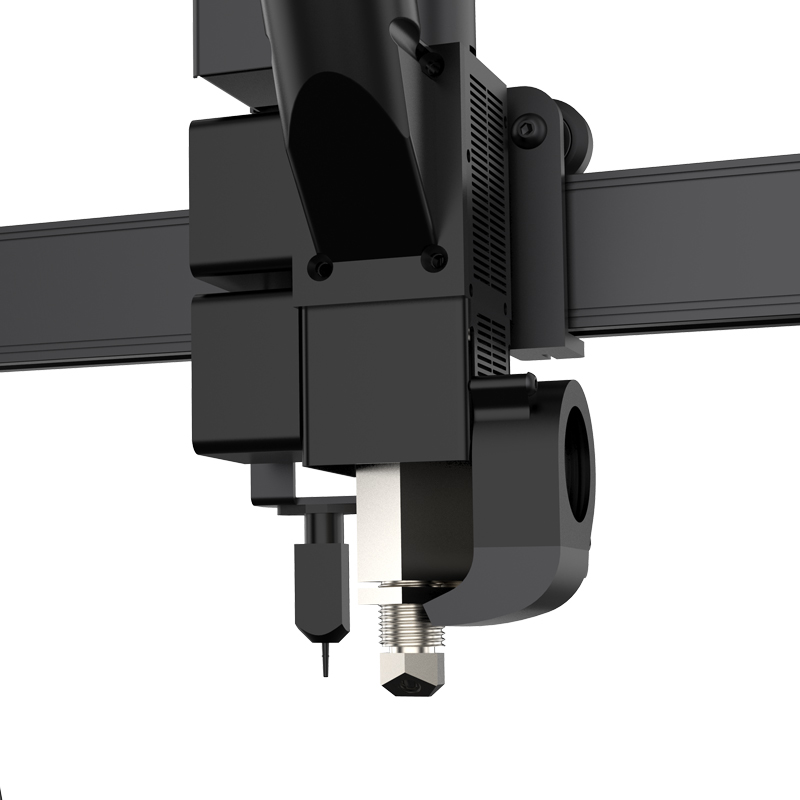

Pellet extrusion is different from filament extruder. Pellet extruder uses screw method to melt pellet material from barrel and convey it through heated nozzle (die). Basically, the pellets are fed into the feeder inlet. They are then pushed through a barrel with multiple heating sections, where they are heated to soften. Once softened to the desired consistency, the screw mechanism generates enough pressure to eject the softened material through the nozzle onto the platform, creating a 3D print layer by layer. Compared with filament extrusion, the process is more complicated, but it does have several benefits.

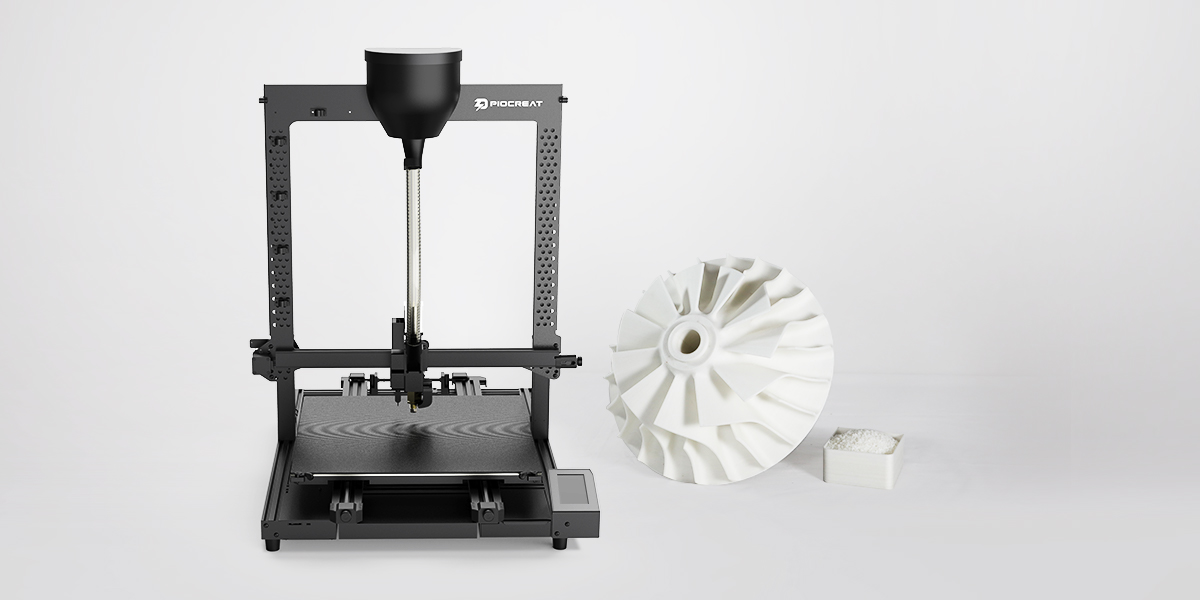

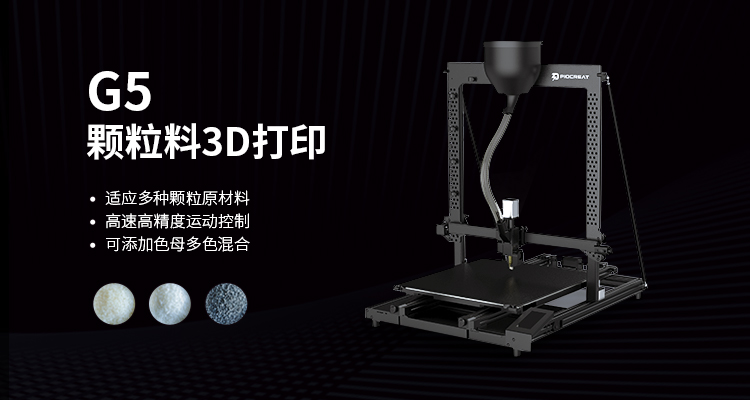

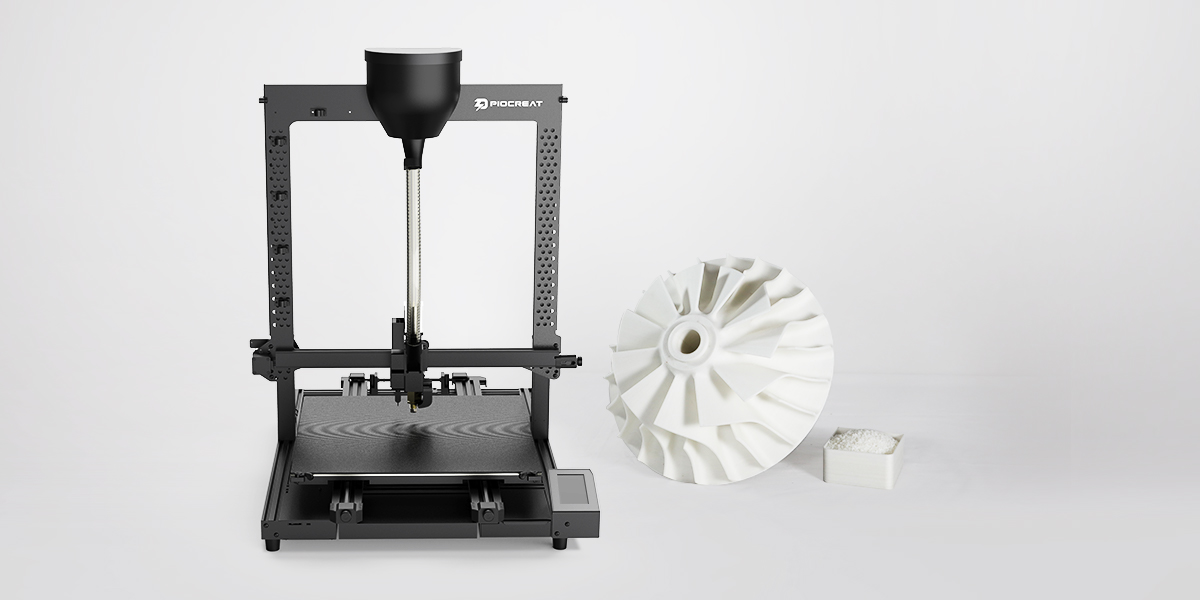

At present, as a well-known

industrial-grade 3D printer manufacturer at home and abroad, Chuangxiang Sandi, the G5 particle 3D printer, which was launched some time ago, has attracted widespread attention as soon as it was launched. As a desktop industrial-grade 3D printer, G5 uses particle fusion technology, which is different from traditional wire fusion technology. G5 directly uses standard plastic particles as printing consumables. Compared with wire materials, the cost of materials is lower and the extrusion The molding speed is faster. Not only that, G5 is also the first and first particulate 3D printer in China. So, in which industries can such a desktop industrial 3D printer be used?

一, the application in the manufacturing industry

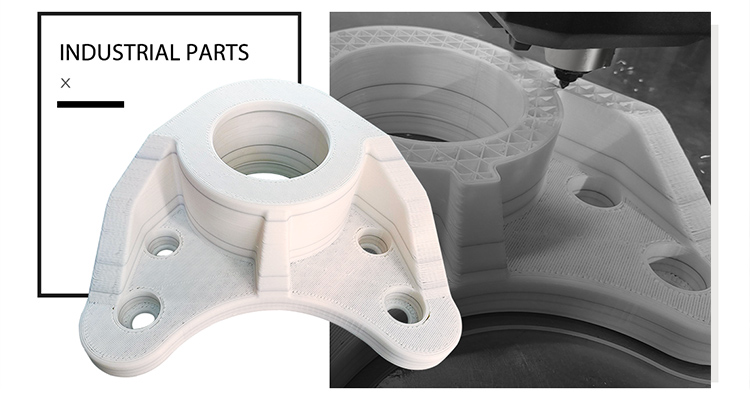

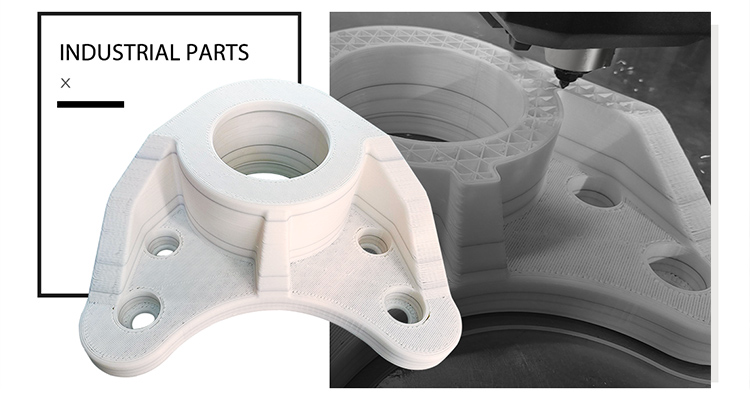

1. Printing of various parts: G5 can not only use plastic particles, but also composite material particles, such as metal, ceramic and other composite particles. Just because it can use a variety of consumables with different attributes, G5 can design for different parts and print them directly and quickly to meet different levels of needs and save time and cost.

2. The efficiency of commission manufacturing: We all know that 3D printing technology is printing layer by layer, whether it is light curing or thermal melting technology. In addition to the faster printing speed of light curing technology, the printing speed of 3D printers using FDM technology is generally slow. The granular 3D printer G5 is different. Due to the practical granular consumables, the extrusion nozzle is larger and the extruded material is more. Therefore, it is much higher than the general FDM3D printer in terms of printing and forming, helping enterprises to improve production efficiency.

3. Improve the overall quality of mass-manufactured products: G5 can improve the overall mass-manufactured product quality for industry users, especially highly customized products. Due to the characteristics of 3D printing, it is more suitable for printing highly customized services for the industry, and the automated printing mode can also reduce product problems such as unqualified products and non-compliance with customized needs.

二, the application of education industry

1. Modern education uses 3D printing to improve the quality of students: to achieve an organic combination of the virtual world and the physical world, G5 can enable the campus to train students in innovation and practical ability, turn students’ creativity and imagination into reality, and Greatly develop students' hands-on and brain-working abilities, thereby realizing the reform of school training methods.

2. A new attempt to educate public welfare: Under the background of the technological trend of 3D printing, the promotion and popularization of 3D printing technology in my country still has some gaps with foreign countries. In order to let more people come into contact with 3D printing technology, 3D printers The education industry has become an attempt at a new way of education.

3. Make learning more interesting: When children not only enjoy the process, but also increase their creativity and deepen their understanding of the subject. Three-dimensional visual effects are an amazing learning tool, and 3D printing is used to help explain difficult concepts.

三, the application of the construction industry

1. Model modification: Use G5 particulate matter 3D printer to realize any idea you have, transform your idea into a visible realistic model, share, discuss, improve with your customers or your fans, and improve customer satisfaction and Reduce the dispute rate.

2. Urban planning: Urban planning no longer displays city planning blueprints in a flat way, and practical G5 particle 3D printer printing allows city planning to be displayed in a three-dimensional form within a few hours, bringing all visionary ideas and concepts It's all visible.

3. Sand table: Real estate companies no longer have to spend hundreds of thousands to find a company that specializes in sand tables to display sand tables for their upcoming real estate. They use G5 particle 3D printers to directly print real estate renderings, eliminating the need for complicated communication. Problems such as long production process, expensive production cost, and long production cycle.

四, the application of the furniture industry

1. Simple and convenient: using the advantages of 3D printing technology, no matter how complicated the furniture product is, as long as the G5 particle 3D printer can design the furniture model, consumers can choose the furniture style and style that they are satisfied with; of course, it can also be directly Use a 3D printer to directly print out furniture prototypes; greatly shorten product design time and improve production efficiency.

2. Personalized customization: For some furniture products that are large in size and not easy to carry, furniture accessory manufacturers have also developed effective segmentation and combination systems. They only need to use 3D printing technology to produce sofa legs, sofa chassis, sofa functional frames, etc. Some components can be simply assembled by users when they are in use, and they can even provide customers with personalized services such as self-designed furniture products and accessories.

五. Application in the art industry

1. Reproduction of cultural relics: use 3D scanning technology to obtain a three-dimensional model of the reproduced cultural relics, and then use the G5 particle 3D printer to directly copy and print to obtain the replicas, and then reproduce the replicas on the replicas to form batch production.

2. Digital sculpture: The combination of digital sculpture and 3D printing technology enables artists to realize many novel ideas in a short time, making good design concepts in their minds materialize quickly, and design inspiration is no longer a piece of drawing, but a piece of paper. A materialized model that is easy to understand.

3. Art work design: Designers no longer need to consider the craftsmanship in the production process. 3D printers realize any complex structure and geometric shapes, which can perfectly handle the consistency and simplicity of the work from design to production.