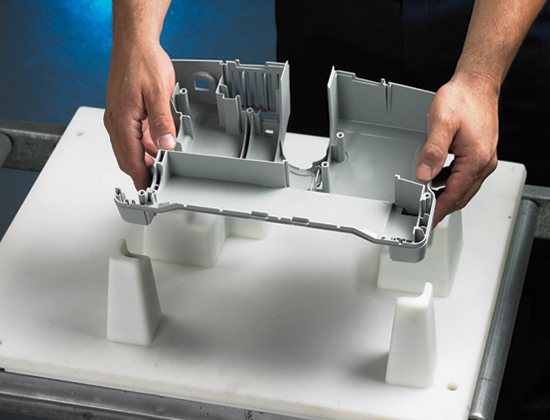

Manufacturing enterprises have been committed to improving efficiency and reducing costs. Lean production technology plays an irreplaceable role in this process. The implementation of inspection tools, fixtures and fixtures in the production line helps to improve operation efficiency. However, the production cost of fixture is very high and the cycle is very long, which seriously affects the production efficiency. 3D printing allows a high degree of customization with complex parts in the design. With its excellent speed and accuracy, it has become an ideal solution for the production of inspection tools, fixtures and fixtures.

Reduce costs and improve profitability

Compared with NC machine tool processing, the production time of 3D printing fixture and fixture is only 25%, less material is wasted, the operation complexity will not be increased, and almost labor-free production can be realized. All this allows you to be creative and design and test through rapid iterations. Together, these features increase production and help you enter the market faster.

Improve productivity. Improve quality

Shorten the development cycle from months to weeks. With the flexibility of 3D printing fixtures and fixtures, you can print your own customized manufacturing tools - lightweight alignment tools and robust fixtures made of industrial grade materials. Faster, more efficient and more profitable operation.

Customized to improve ergonomics

Make strong and light fixtures and fixtures. Various tools are designed for better ergonomics and higher safety, and are specially customized for operation and operators, which is very suitable for your production environment.

Reconstruction of plant workshop

3D printing reduces the manufacturing cost of fixtures and fixtures. The combination of print prototype and grabcad print shortens the design cycle. Developing durable materials means you can print fixtures that meet stringent manufacturing requirements. 3D printing breaks through traditional possibilities.

Now, we have

pellet 3D printer, we can put forward more requirements for the performance of fixture. Because our pellet 3D printer can print a variety of materials, such as PETG, ABS, PA, PC and PLA, and can also add glass fiber and other composite materials for printing, which can fully meet the application needs of fixtures and fixtures.