2022/04/22

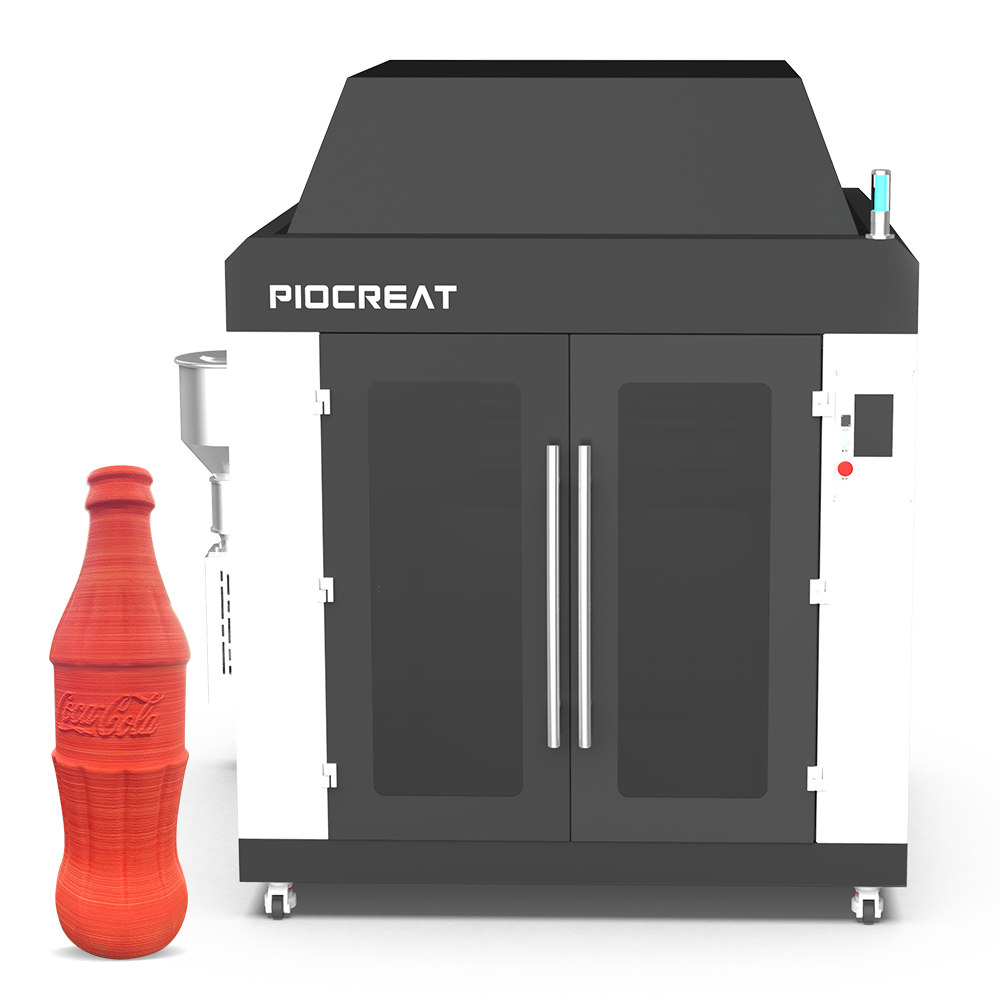

Large working space

Working space: 3725×2500×1330mm. The internal temperature is constant at 35-50 °C,which fully meets the need of various large parts.

Workbench design

Can be divided into 6 independently controlled heating table. According to the printed model, zone heating control can be selective, avoid effectively electricity wasting, and improves the stability of the bottom layer of the printing model.

High flow screw extrusion design

Equipped with 3-8mm large flow screw extrusion nozzle. The maximum printing speed can reach 100kg/h. To ensuring the stability and accuracy of the gantry (±0.02mm/1000mm), the printing speed is 10m/min and the processing speed is 15m/min.

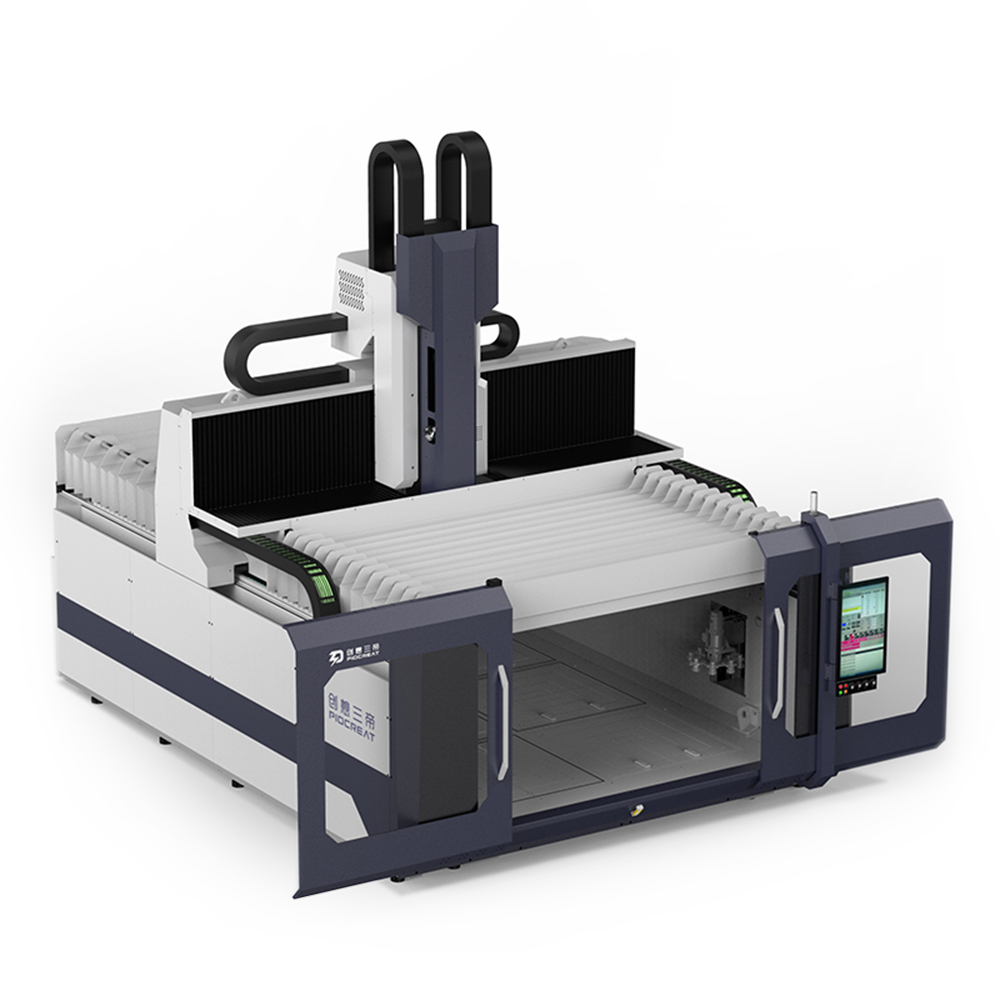

High-speed and high-precision five-axis head

Equipped with 8.5KW/24000 high-speed hvct. Using precision five-axis head, A axis + 120°C, C axis + 320°C, machinable with plastic, carbon fiber and non-ferrous metals.

Wide range of printing materials

Can meet the application needs of different fields. It is suitable for printing all kinds of thermoplastic particles, special mixtures materials, and ceramics and metal materials. Supports a variety of fiber composite thermoplastic polymer materials

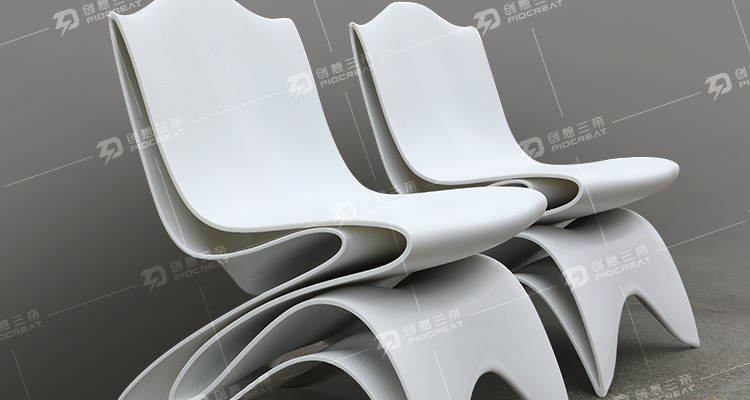

Application field

Applied in various fields. Suitable for producing large to very large thermoplastic materials parts,molds, models and industrial tools, etc. Widely used in aerospace, automobile manufacturing, wind power, yacht and ship, home life, urban landscape and other composite materials field.