In today's modern society with the continuous development of science and technology, no matter which industry's products, the demand for molds is highly dependent. Many parts in most products need to be manufactured by molding (injection, blow molding and silica gel) or casting (investment molding, sanding and spinning). Therefore, no matter what industry or application, manufacturing molds can not only improve efficiency and profit, but also ensure the quality of products.

In the past, CNC machining was the mainstream technology for manufacturing molds. Although the manufactured molds can provide reliable and effective results, the practical application of this technology is very time-consuming and expensive, so many products also increase a lot of costs. Therefore, many mold manufacturing enterprises are looking for more effective, time-saving and cost-saving methods to replace CNC technology.

At present, the most suitable method for mold manufacturing is additive manufacturing (i.e. 3D printing technology). At this stage, 3D printing technology and practical materials (such as plastics, rubber, composite materials, metals, ceramics, wax, sand, etc.) have brought great convenience to many industries such as automobile, aerospace and medical treatment. Especially in foreign countries, many enterprises have integrated 3D printer supply chains, The most used industry is mold manufacturing. So, what are the advantages of using professional mold 3D printer in mold manufacturing?

1.Reduce mold manufacturing cycle

As we mentioned earlier, one of the main reasons why mold manufacturing enterprises and industries that need to use molds want to change another mold manufacturing method is the long manufacturing cycle. After the application of 3D printing technology, the whole product development cycle is shortened in the manufacturing mold, and it has become the source of driving innovation. In the past, considering the need to invest a lot of money to manufacture new molds, companies sometimes chose to postpone or give up product design updates. By reducing the production preparation time of the mold and enabling the existing design tools to be updated quickly, the mold 3D printer enables enterprises to afford to replace and improve the mold more frequently. It can make the mold design cycle keep pace with the product design cycle.

2.Reduce the manufacturing cost of mold

This is also one of the main reasons why the technology needs to be replaced. The use of CNC to manufacture molds involves programming, raw material reduction, labor, etc. under these procedures, a wide range of materials and labor need to pay a high cost. When using 3D printing technology, only the graphics and digital model need to be involved, and the rest only need to be handed over to the mold 3D printer to complete by itself, and multiple steps are omitted in the middle. And the need for more materials can use as many materials as possible. There is no need to worry about waste, which can well save the production cost of mold manufacturers and enterprises.

3.It can realize highly customized mold manufacturing

Shorter production cycle, more complex geometry and the ability to reduce the final manufacturing cost enable enterprises to manufacture a large number of personalized chemical tools to support the manufacture of customized parts. Mold 3D printer printing mold is very conducive to customized production, such as medical equipment and medical industry. It can provide surgeons with 3D printed personalized instruments, such as surgical guides and tools, so that they can improve the operation effect and reduce the operation time.

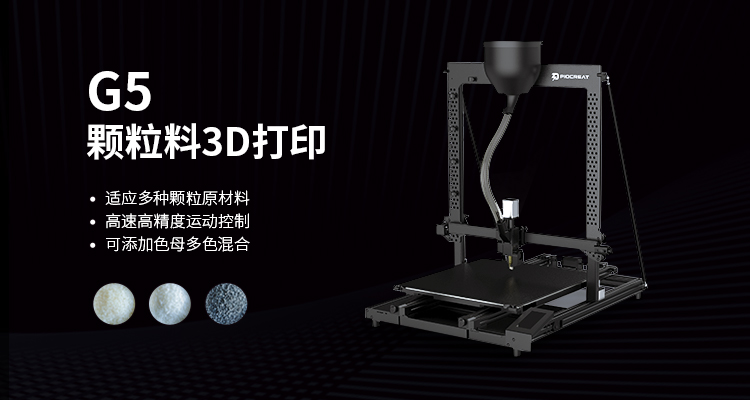

The granular mold 3D printer G5 independently developed by Piocreat uses granular materials instead of traditional wires and is equipped with a screw structure print head design, which increases the printing efficiency by 5-10 times. Low-cost, high-efficiency 3D printing technology meets users' demands for high-speed, high-precision and multi-material 3D printing. At present, G5 has been deeply applied and practiced in the fields of teaching and research, molds, and sculpture. In the future, Chuangxiang Sandi will explore new possibilities in more industries based on particle 3D printing.