Piocreat:Particle melting 3D printing Consumables are cheap, fast and super large

The 3D printing technology is based on the principle of additive manufacturing, and the product can be obtained quickly and efficiently through a computer connected to a

3D printer. Fused deposition 3D printing process (FDM for short) is currently the most popular 3D printing technology, which is widely used due to the low cost of equipment and materials. However, this technology still has some shortcomings, such as high material cost, slow printing speed and unsuitable high-temperature materials.

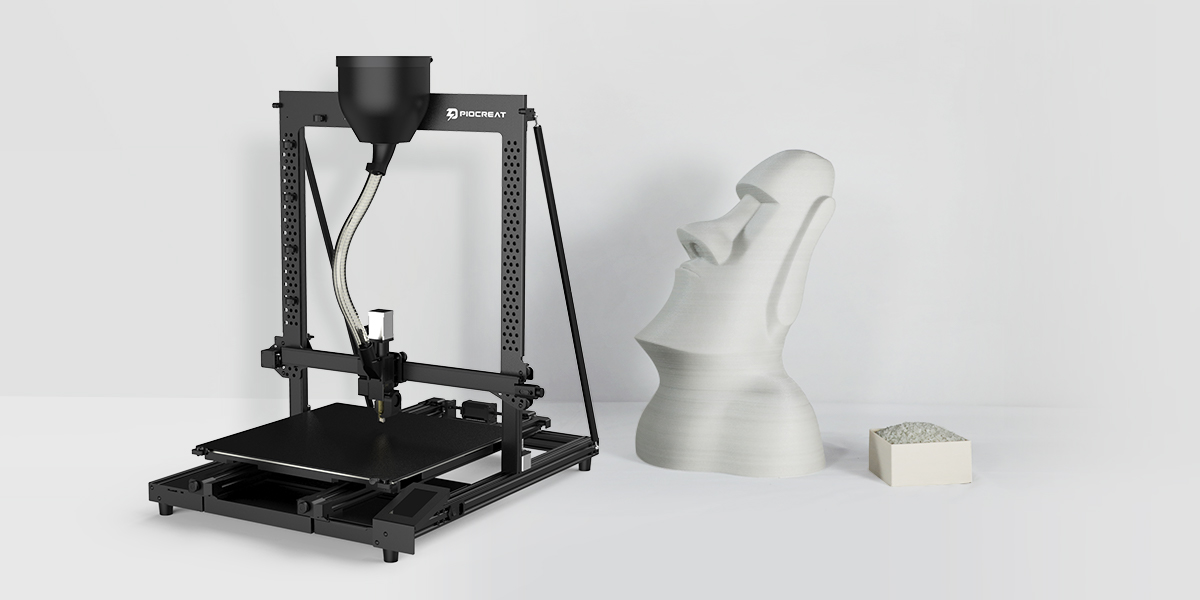

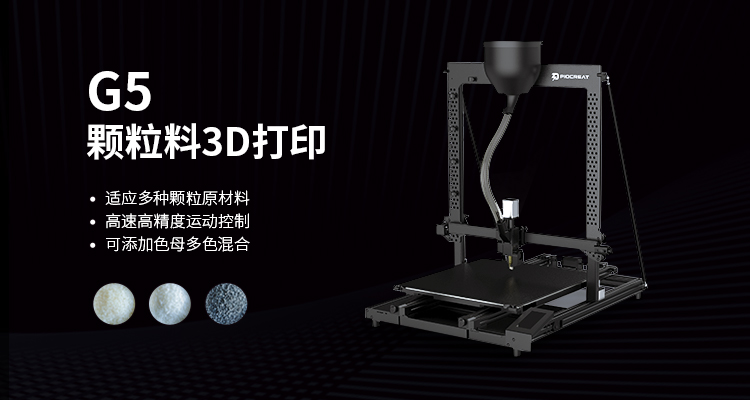

Particle fusion 3D printing uses standard plastic particles and is heated by a vertical spiral rod to extrude the molten material. It can be configured with multiple nozzles to work together. The molding size can be customized. It can print 30 kilograms of material per hour. Standard materials such as ABS, PP, nylon, and TPU can be used. Fiber or copper powder can also be added to form composite materials. Biodegradable materials and recycled materials can also be used. Meet the final use requirements of large sculptures, buildings, doors and windows and other large parts.

Fused deposition process is currently the most widely used additive manufacturing technology in the 3D printing industry. The traditional molten deposition process is to heat and melt the filamentous hot-melt material, and then extrude it through a micro nozzle. Due to the limited efficiency of resistance heating, the flow rate of the extruded material is very low, generally less than 0.1cm3/s, which reduces The forming efficiency and forming speed make this rapid prototyping technology unsuitable for the establishment of large and medium-sized parts; on the other hand, the use of thermoplastic filaments as raw materials limits the types of materials that can be used, and it is difficult to form filaments or have higher hardness at room temperature. Plastics that are not easy to curl are not suitable for this forming process.

In response to these shortcomings, the manufacturer has developed a new type of particle fusion printer. This 3D printer adopts a pellet-feeding screw extrusion device, which can solve the problems of low molding efficiency and slow molding speed of fused deposition molding 3D printers. Moreover, printing materials are not limited to hot-melt materials, which greatly broadens the scope of industry applications.

The emergence of particle fusion 3D printing marks a new step for the 3D printing industry.