Piocreat:Industrial-grade 3D printer manufacturer Piocreat launches heavy-weight particle 3D printing equipment G12

Recently, China’s industrial-grade 3D printer equipment manufacturing service provider, Piocreat, said that for a 3D printing equipment company, the biggest risk may not be its current competitors, but that new 3D printing technologies may appear in the future, which will change the current situation. Some technologies are substituted. In this regard, many industry peers expressed their deep agreement. The

FGF 3D printer that directly uses pellets is a very obvious example. Its appearance and popularity will most likely cause a batch of FDM wire suppliers to lose their jobs.

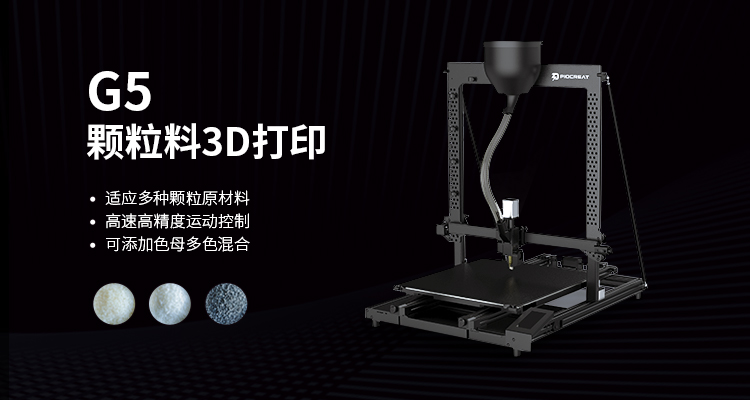

The industrial-grade granular 3D printer G12 developed by the Piocreat Material Addition and Subtraction Group is not an exaggeration, because he has a lot of materials that can be printed. It can be seen from the inside of the "Big Stomach King" 3D printer that its molding system platform is a bit more complicated than a general 3D printer, but the biggest difference lies in its feeding and extruding devices. It can directly use granular raw materials such as ABS/PLA/TPU, pour it into the feed compartment, melt it at high temperature and turn it into a liquid state, and then realize the extrusion of 3D printing materials under the control of a powerful extrusion system. The material used is no longer a wire, which makes its material cost lower, because with a large nozzle, its printing speed is much faster than the FDM wire 3d printer.

To put it simply, FDM technology, the current process of general 3D printing materials in the ecosystem is: ABS/PLA and other granular materials → become wire after drawing → heat and melt and extrude for 3D printing. At present, there are dozens of 3D printing consumables manufacturers in China, most of which are "turning ABS/PLA and other granular materials into wire after drawing."

However, the FDM 3D printer that directly uses granular raw materials makes the process of 3D printing materials in the ecosystem become "ABS/PLA and other granular raw materials → heating and melting and extruding for 3D printing", directly removing the "drawing into wire", Reduce the dimensionality of the industrial chain. In the arena of 3D printing, it is estimated that there will be another wave of renovation and innovation.

It can be seen that in the near future, this type of extrusion system that directly uses granular raw materials for printing, once the technology is more mature and stable, and is widely used by equipment manufacturers, it will definitely smash the jobs of consumable drawing manufacturers in the future. It is worth mentioning that the G12 granular 3D printer of Chuangxiang Sandi supports a wider range of materials, but in terms of print quality related indicators, there is still a certain distance from the existing wire-type 3D printers.

Globally, innovations in 3D printing technology emerge in endlessly. In addition to impacting the 3D printing industry, they also often have a profound impact on some manufacturing sectors. The popularity and popularity of new technologies depends on many factors. The existing ecosystem still has a certain life cycle. 3D printing wire suppliers will not completely lose their jobs in the next few years.