As a new era of design and production, 3D printing technology has brought extensive changes. Governments, scientific research institutes and enterprises all over the world have vigorously promoted and developed 3D printing technology and its application in various industries. Especially in the jewelry industry, the combination of wax spraying 3D printing technology and paraffin casting technology has been widely used, which can make complex and unique jewelry casting. However, the advantages of small forming limitations and high forming accuracy of 3D printing technology have not been fully utilized.

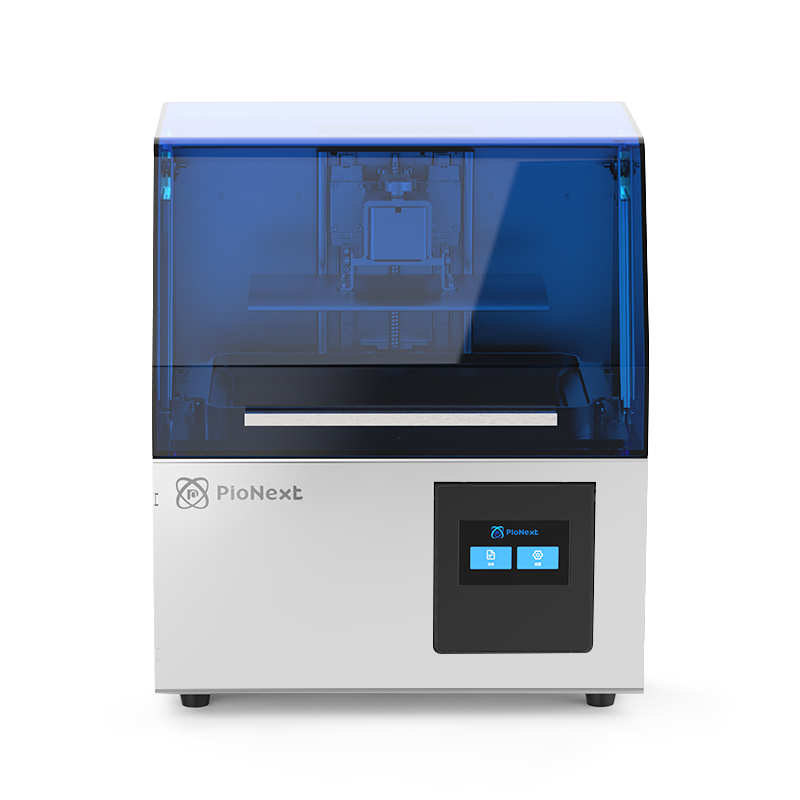

The main reason is that the advantages of small limitation and high forming accuracy of 3D printing technology are not applied to the innovative design of jewelry. Below, piocreat3d Xiaobian carries out 3D printing jewelry design and Application Research on forming structure, internal suspension movable structure and shaft structure from the perspective of jewelry making.

In recent years, digital manufacturing technology has made a major breakthrough. Various markets also appear and gradually accept 3D printing products. At the same time, the application of advanced 3D printing and digital technology creates unprecedented opportunities for Chinese jewelry. Therefore, the printing jewelry technology is divided into five steps:

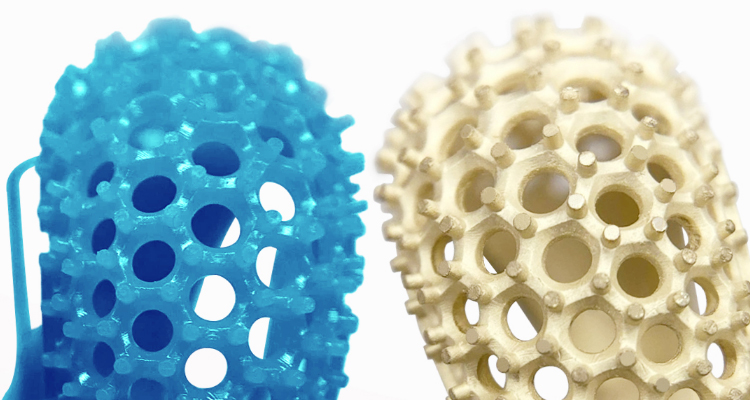

① Use a high ratio 3D printer to print the design model into wax model. This wax mold has this saturated blue color, and its density and surface characteristics are similar to those of traditional casting wax. It is modeled and printed by multi jet design. Its working principle is to sweep the melted wax through the structural construction area through several nozzles and deposit it on the aluminum platform layer by layer. When the heated 3D printing material is sprayed on the construction board, the wax will solidify. Another wax with low melting stability is deposited under the suspended end of the design model as a support material. After printing, take the model out of the tray and put it in hot water to melt the supporting material.

② Put the model into a container containing liquid gypsum. When the gypsum solidifies, the wax will melt in the furnace and finally get the mold of the gypsum.

③ The molten metal is poured into the mold through pouring and hardened.

④ Break the plaster mold and a new jewelry is born

⑤ The jewelry is simply polished, and finally carefully cleaned and polished by hand.