3D printing has become a trend and began to be widely used in the design field, especially in industrial design and digital product mold opening. It can complete the printing of a mold in a few hours, saving the development time of many products to the market. The following small series will introduce the method of selecting industrial grade 3D printer.

Method of selecting

industrial 3D printer1. Explicit requirements:

The price range of industrial 3D printers ranges from hundreds of thousands to tens of millions. Common technologies include FDM, SLM, polyjet, MJP, SLA, DLP, EBM, etc. Each technology is only similar to the traditional turning, milling, planing and grinding processes, and the solution is limited. Therefore, when selecting "how do you want to use 3D printer", you must determine the type of technical process required? What kind of result do you want? Someone wants to buy a printing hand board to meet the verification of assembly structure; Some people want to make finished parts to meet the use requirements. The demand determines the size, specification, material type and forming accuracy of the purchased equipment. The price of industrial 3D printer is directly proportional to the forming size and the quantity of materials. In addition to the purpose of scientific research, the purchased equipment shall not be too large as far as possible to meet the demand.

2. Consider the use of environmental factors:

Different technologies have different requirements for 3D printing equipment. Consumer machines have all the simple requirements for printing houses, which are usually places with good indoor ventilation. SLA and DLP adopt open storage resin, with the highest environmental requirements, constant temperature and humidity, the best temperature is controlled at 22-26, the humidity is 40%, the amount of indoor ultraviolet light is low, natural light is avoided, and special printing places need to be provided.

For industrial grade metal 3D printers, whether it is powder discharge in the cabinet, electron beam or coaxial powder feeding, the requirements for the environment are much looser. The industrial

pellet 3D printer has lower requirements for the environment. Environmental friendly particle materials, direct particle printing, will not produce dust. When installing 3D printing equipment, the equipment size and auxiliary equipment size shall also be comprehensively considered. Sometimes it is necessary to transport resin tanks or printers with trailers, and reserve processing space, etc. Before purchasing equipment, the equipment supplier must be clearly informed of the site they can provide and plan the site in advance.

3. Operator training:

3D printing preparation: emphasize software operation in 3D data processing, supporting design and layout. At present, the slicing software used by many 3D printing manufacturers are customized modules of materialise, and some are developed or acquired by themselves. Therefore, it is necessary to consider whether our engineers are familiar with 3D modeling and whether 3D printer manufacturers have training.

4. Selection of consumables:

The rapid development of new materials is an important driving force for the rapid development of 3D printing industry. The applicable material states for 3D printing are solid, liquid and gas, and the material types are metal, resin, polymer, ceramic, inorganic lipid, biomaterial, etc. 3D printing can use a variety of materials, but in reality, there are usually no materials that fully meet the requirements. In a certain category, the existing 3D printing technology can only print a limited number of materials. It is recommended that the manufacturer of industrial 3D printing equipment provide a detailed material parameter table when selecting materials to understand whether there are alternative or similar materials that can meet the final requirements.

5. After sales service:

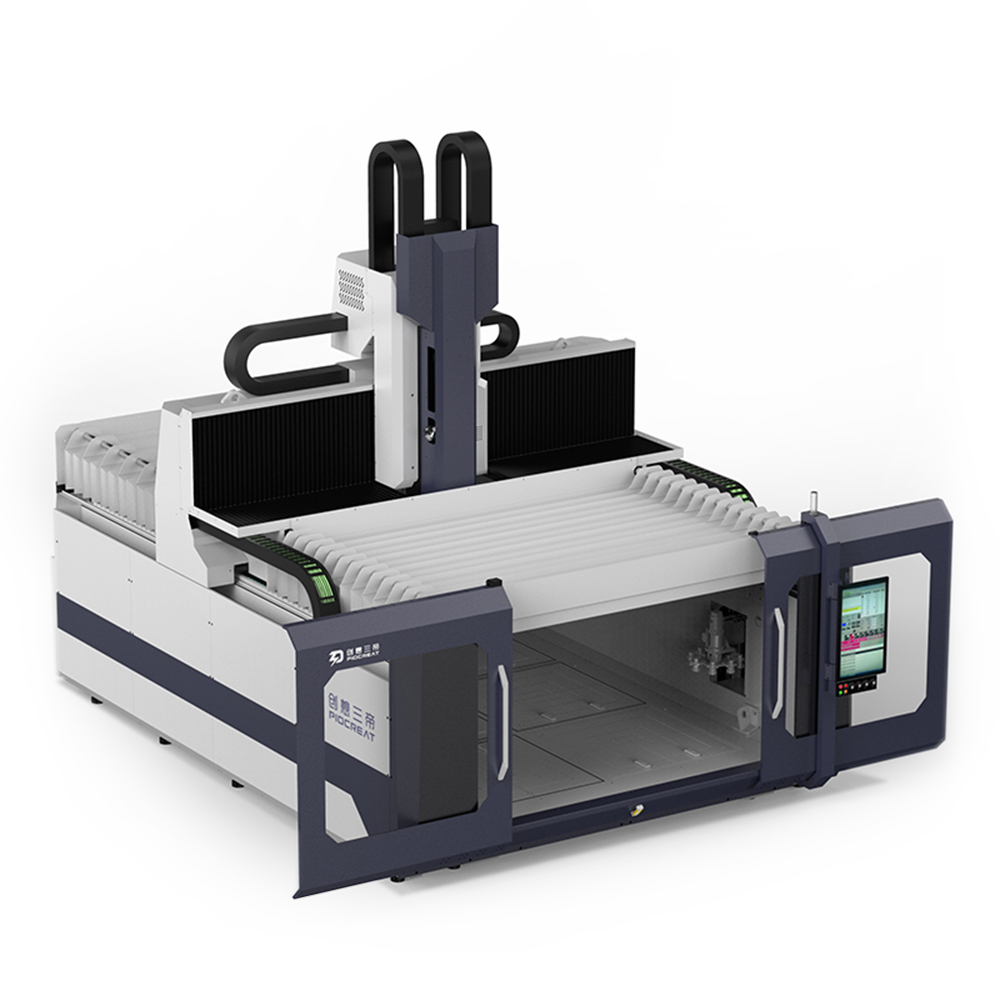

Having abundant spare parts and mature technology is very important for the after-sales team. At present, many industrial 3D printer manufacturers have, such as G12 and G40 of chuangxiang three emperors. 3D printing equipment is highly automated. As long as we strictly follow the manufacturer's process, the failure rate is usually very low. Of course, some equipment in the market is of poor quality, so professional procurement consultants can get twice the result with half the effort. After all, every industrial 3D printer is expensive.

The above is how to choose industrial 3D printer? The introduction of the method of selecting industrial grade 3D printer is expected to help you. At the same time, if you want to know more about 3D printer information, you can pay attention to the update of Zhicheng industry.