At present, due to the excessive hype of consumer 3D printers by the media, some consumers' understanding of them only stays at the level of making a beautiful gift for children, while they lack understanding of the performance and potential of industrial 3D printing. At the same time, many traditional enterprises are not clear about the potential of 3D printing technology and think that it is just a flashy gimmick. At the initial stage of the development of 3D printing technology, the cost of equipment and materials is high, the printing quality is not high, and the technology is not mature enough. However, in recent years, industrial 3D printing technology has developed rapidly, and new process methods with high speed, high performance and high quality have emerged. For example, high-end manufacturing industries such as aerospace and automobile have actively applied industrial 3D printing technology to carry out product upgrading and new product research and development, and achieved good results.

History is always strikingly similar. Like the train and printing, this personal travel revolution was triggered by scale and standardization. Before the invention of the train, people relied on carriages to travel. Although they were personalized, they were inefficient; After the invention of the train, its more efficient, faster and cheaper characteristics quickly crushed the carriage business and greatly expanded the scope of people's activities. However, the scale of the train is at the expense of personalization. The train always follows the same track and the same route. People even need to adjust their living habits according to the train route and departure time. The standardized train has its inherent defects. Finally, the arrival of cars in 1919 rewrites the city map and changes the concept of travel. Compared with the steam train subject to the track, cars give passengers greater autonomy and facilitate people's travel. People no longer have to travel according to the schedule of rail trains. At that time, the market share of the railway was shrinking, just as the 3D printing technology that can rapidly process high-quality parts in batches gradually replaced the traditional manufacturing technology.

1. impact of industrial 3D printing technology on parts design

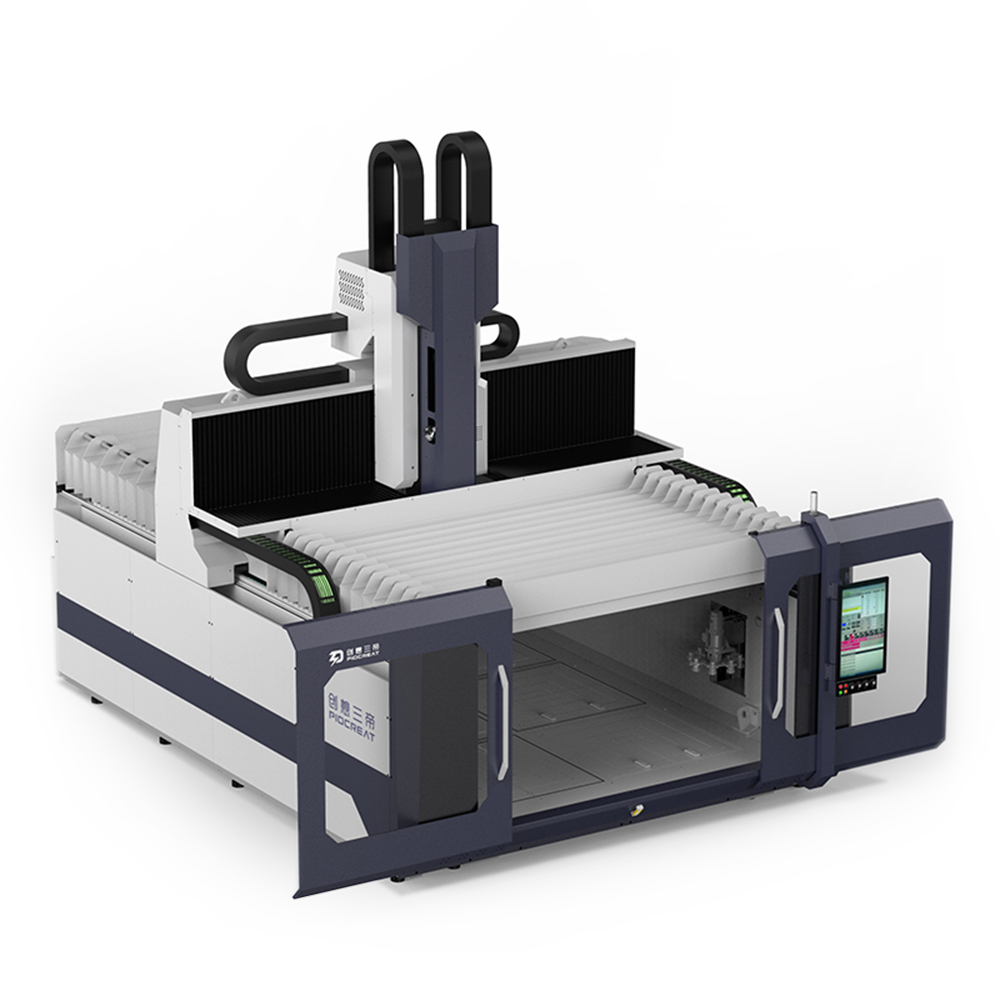

Software simulation can be used for topology optimization design and performance analysis and evaluation in parts design. Compared with traditional manufacturing process, the calculation results of topology optimization can be used to a greater extent, and the weight reduction effect is obvious. The product design facing the traditional manufacturing process needs to be decomposed into many parts according to the processing capacity. The development of

pellet 3D printing technology can integrate many parts for design, greatly reducing the number of parts, greatly improving the reliability, and reducing the workload of machine assembly. For example, for the box and cooling air duct assembled by multiple parts, 3D printing processing not only saves the sealing materials and conductive materials between the assembled parts, but also the cross-section design and route design of the flow channel and air duct meet the requirements of fluid mechanics and improve the flow efficiency. If the characteristics of additive manufacturing and die-casting or injection mold are comprehensively considered in the design of parts and complete machine, the mold design and manufacturing before mass production can be carried out at the same time of small batch additive processing. The design work can save the time of mold design, manufacturing and testing, and the product can be put on the market faster.

2. impact of industrial 3D printing technology on product R & D process

The R & D process of new products facing the traditional manufacturing process can only be serial basically. After the design is completed, it waits for processing and assembly before testing. There are many parts, and the design and processing time is also long. The fitting accuracy of parts is poor. Sometimes problems are found and solved during assembly and testing, resulting in a long R & D cycle. For the new product R & D process for additive manufacturing, some work can be carried out in parallel, reducing the number of parts, design and processing time, and minimizing the R & D cycle.

Analyze the whole R & D process: in the product modeling stage, multiple different product shapes are compared and evaluated through 3D printing, which can make the modeling and conceptual design more perfect and shorten the cycle, and win sufficient time for the later detailed design; In the prototype stage, 3D printing technology is used to process the product structure and some circuit boards, which can save the processing time of prototype parts, so as to have sufficient time to test the prototype and find and solve potential problems as soon as possible; In the small batch trial production stage, industrial 3D printing technology can be used to quickly produce small batch of parts, and the assembly line trial production of the whole product can be carried out, so that the product can reach the batch production status faster; At the same time of formal batch production, industrial 3D printing technology can be used for small batch production, so as to cooperate with market promotion, customer trial and other marketing, so that the products can be brought to the market faster.

3. prospect of product development for industrial 3D printing

In june2019, Europe released the European Industrial outlook 2030, which identified additive manufacturing as the key to the future strategic growth of European industry. Due to the reduction of the restriction of 3D printing technology on product design process, the product design software can develop faster in the direction of intelligence. The previous computer-aided design will develop into artificial intelligence aided design. The product design will be more reasonable and efficient, greatly reducing the workload of design engineers, and can focus more on the realization and improvement of product functions. Product R & D organization form and product R & D process will also change for additive manufacturing and intelligent design.

With the continuous popularization of industrial 3D printing technology, enterprises need to increase the attempt of additive manufacturing in the process of product planning and design, so that product strategy, design thinking, system process and supply chain can gradually adapt to the changes brought about by additive manufacturing. For enterprises, the change can not be achieved overnight. They need to make planning and layout in all aspects and keep trying to form a development route of additive manufacturing that is suitable for enterprises and product characteristics. Just like the book "great disruption - from 3D printing to 3D manufacturing", the authors ricksmith and Mickey Frey systematically investigated the previous industrial changes since the 15th century. Each major change is accompanied by a second wave. At present, big data, cloud computing and other technologies are booming, and the traditional standardized manufacturing has been unable to adapt to the rapidly changing market requirements. The emerging 3D printing technology is characterized by its digitalization, customization The new face of liberalization has emerged in people's vision. It will be perfectly integrated with these emerging network technologies and lead the era of 3D manufacturing.