Previously, 3D printing technology in the automobile industry was mainly used by automobile manufacturers to manufacture automobile prototypes to check their shape and applicability. And now? The automotive industry is facing various demands, such as higher demand for design updates and performance, and the demand for optimizing production, simplifying supply chain and logistics. 3D printing can help meet these challenges.

Many automobile companies around the world have begun to realize the advantages that 3D printing brings to the automobile industry. 3D printing can be used in the automobile assembly line to manufacture lighter, faster turnaround auto parts, components and prototypes, as well as the production of replacement and spare parts.

Five applications of 3D printing in the automobile industry

1. For design;

2. Direct manufacturing of complex structural parts;

3. Manufacturing of lightweight structural parts on automobiles;

4. Customizing special workpieces and testing instruments;

5. Production of vehicle model.

Impact of 3D printing on automobile industry

1、 Design level

Traditionally, planners design a car from drawings, and then use design software to make accurate data and 3D models of the conceptualized car shape. If you don't have 3D printing skills, the next step is the clay model. The designer should first knock like a carpenter to make the skeleton of a car, and then like a mason, mix talcum powder, vaseline, and industrial wax to make putty, and then paint it on the skeleton layer by layer. Finally, like an artist, scrape out the shape of the putty and make a model at the end to see what the model on the painting paper and computer is actually. This process is still the process of the handicraft era, time-consuming and laborious.

With 3D printing technology, as long as planners input the 3D model made by computers into the 3D printer, the 3D printer will be able to print the sludge model 3D quickly, which can greatly improve the efficiency and step into the information age. Not only the body shell, but also all parts in the car, such as gear shift handle, instrument panel, glove box, door handle, etc., have a process from computer to real object.

With 3D printing technology, engineers can plan the model on the computer, and designers can obtain the printed model of the entity in just a few minutes. Then each professional in the entire development team can modify the printed model on the basis of the printed model, and share the improvement of the design scheme with others in the team in real time to complete the "what you see is what you get", greatly increasing the power of the car design.

2、 Development level

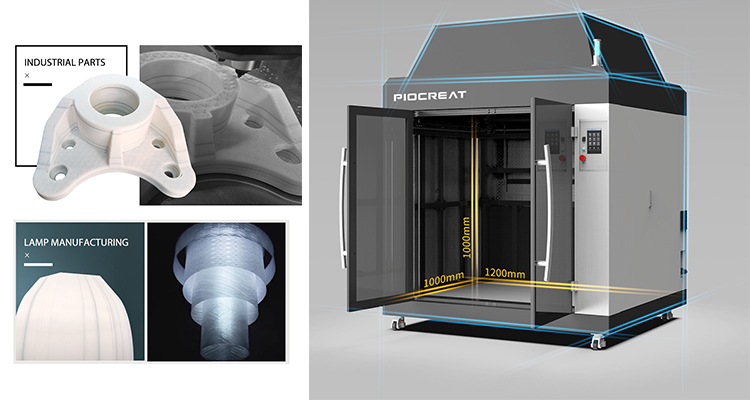

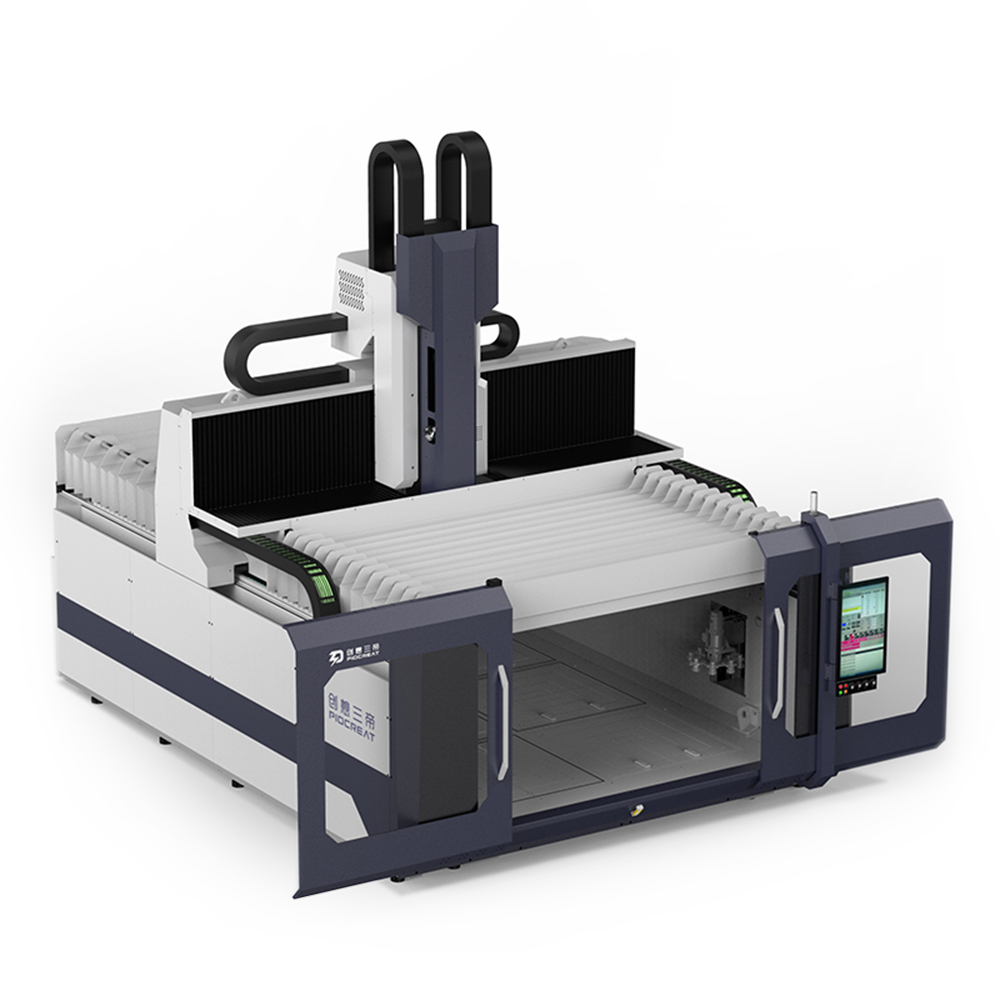

The biggest advantage of 3D printing technology is that it can easily and quickly produce high-precision and complex parts, while the car just has many high-precision parts with complex appearance. For high-end cars with small batch size that cannot meet the mold opening plan, 3D printing can also directly produce some materials to meet the needs of parts, reducing costs, such as F1 racing cars, luxury cars, and some parts of supercar.

As for parts produced in large quantities, 3D printing may not be applicable due to material and cost reasons. However, 3D printing can be used to make parts, especially some parts with very complex appearance, high precision requirements and need repeated debugging. 3D printing can quickly produce the most appropriate parts to ensure that the best parts are selected for the finalized production. The advantages of 3D printing are that the overall development power is increased, the marketing cycle is shortened, and the time and cost are reduced.

To sum up, 3D printing technology can significantly reduce the cost in the process of car development and production, improve the working power, and reduce the development time of new models and parts. These will be reflected in the quotation and quality of cars. Cars with better quality, better skills, and cheaper quotation will be presented due to the popularity of 3D printing technology, and consumers will benefit from it.