After several years of vigorous development of 3d printing technology, 3d printers have been basically popularized throughout the country, and even entered well-off families to print some 3d printing models for children. When many parents use the 3D printer, it is easy to see that the base of the 3D printing model cannot stick. We commonly call this phenomenon "edge warping". The edge warping in the 3D printing project is a headache for many parents. Piocreate has accumulated 3d printing experience over the past seven years, and summarized six efficient solutions to the problem of 3d printer edge warping.

Piostreak

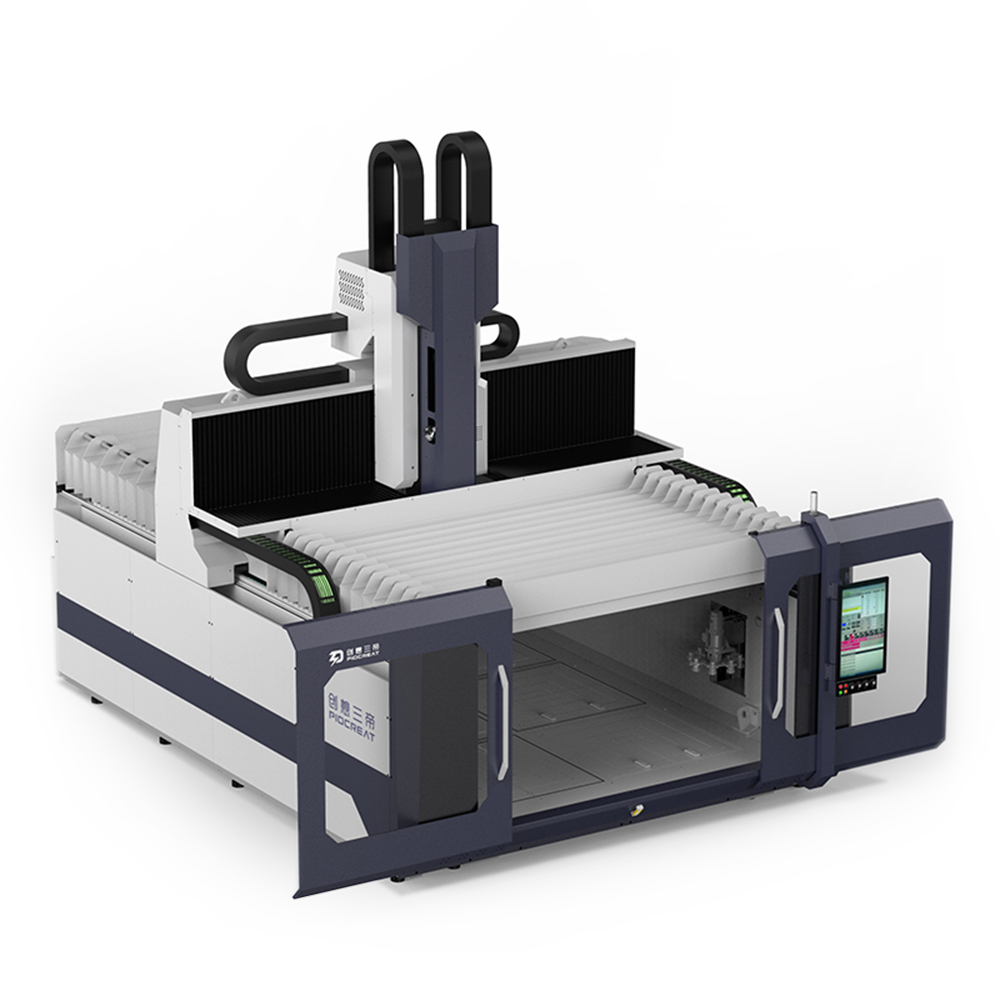

industrial pellet 3d printer1、 Why does edge warping appear during 3d printing?

If we want to solve the edge warping problem of 3D printers, we must understand from the root cause that the edge warping is caused.

① It is affected by the thermal expansion and cold contraction of 3d printing materials. When we use the 3D printer to print the model, the 3D printing material extruded from the nozzle will shrink during the cooling process, which is easy to cause the edge of the 3D printing model to tilt up, and the hot bed of the 3D printer will be separated.

② Sometimes, because the bottom surface of the 3D printing model is not large enough, the effect of shrinkage is not obvious during the 3D printing process. When the 3D printing model is large enough, the shrinkage per unit area accumulates, while the inward tension is quite large, causing edge warping.

③ Another situation is that some parents failed to reach the corresponding temperature of the hot bed for the convenience of drawing, which led to the hot bed temperature. They could not stick to the base of the 3D printing model, which led to the warping of the bottom of the model.

2、 Efficient and fast solution to 3d printer warping

① Any 3D printer of Piocreat is equipped with a hot bed. Users are using the 3D printer to adjust the temperature of the hot bed to the melting point of the corresponding 3D printing materials. Let me kindly remind you that when printing ABS, the hot bed temperature is about 110 degrees, while PLA is relatively easy to adjust to 60 degrees; The nylon should also be adjusted to about 60 degrees, and then add the corresponding glue.

② Of course, some customers buy 3D printers without hot beds, which can only be relatively troublesome. Apply some glue on the bottom of the 3D printing model, and stick the base with glue. You can choose to buy PVP solid adhesive, textured paper, etc. in the market.

③ Thickened 3d printing model base width,As we all know with 3D printers, the wider the printing line, the more 3D printing materials will be squeezed out of the extruder, which will lead to greater extrusion force on the platform, so as to increase the adhesion between the model and the platform and prevent edge warping.

④ Reduce the printing speed of 3d printer,As we know, many customers use 3D printers. In order to improve printing speed, 3D printing models are basically edge warped. According to the Piocreat 3D printing manufacturer, you have accumulated many years of 3D printing experience, and you can control the speed of the 3D printer to 50mm/s-60mm/s.

⑤ When printing the bottom of the model, do not turn on the fan of the 3d printer,When we use a 3D printer to print a large area model, we should try not to turn on the fan. Fan blowing can speed up the cooling of the model. If it is too late to print the next layer, it will cool down, which may cause deformation.