Integrated material increase and reduction scheme makes industrial manufacturing simpler

In high-end manufacturing applications, the trend of customized production is becoming more and more obvious, and the demand for large structural parts with small batch, large size and complex modeling is increasing. However, the high cost, long production cycle, and too large size make it difficult to open the mold, which lead to the traditional method of making molds before making finished products no longer applicable.

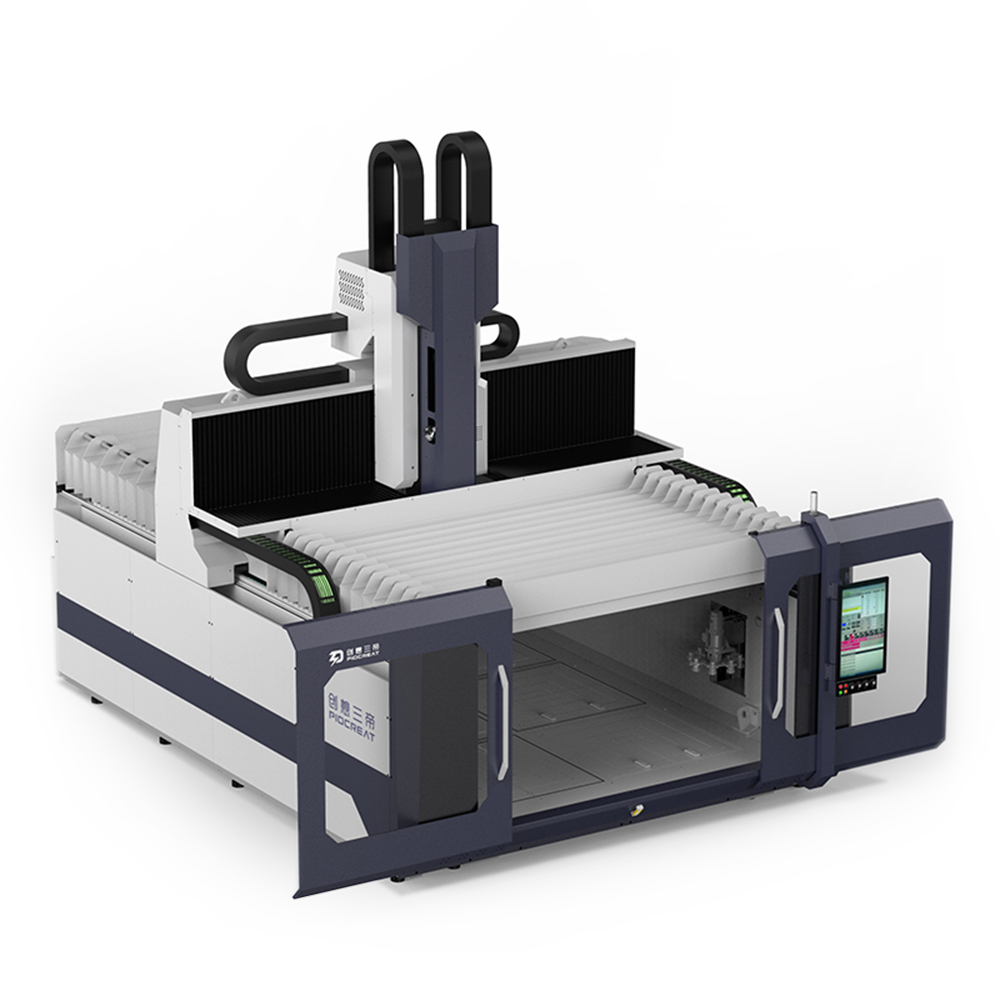

Piocreat, based on the self-developed integrated additive manufacturing and five axis material reduction processing machine (G40), launched an integrated solution for large-scale composite products in high-end manufacturing, designed and manufactured the final products directly according to the model, without mold opening, and has the advantages of stronger molding ability, shorter production cycle and higher efficiency, which can effectively subvert the traditional manufacturing methods, It is an ideal solution for rapid prototyping and low-cost manufacturing of large size workpieces, and has a promising application prospect.

1.3D has stronger printing and forming ability, which maximizes the freedom of design. Compared with traditional manufacturing methods, rapid prototyping technology can realize product structures with various multi-dimensional surfaces and complex shapes, and can optimize the structure through design, making fewer parts, more conducive to product structure design, and effectively accelerating product iteration and production process.

2. Larger size and higher precision. Compared with other 3D printing processes on the market, Piocreat's integrated solution for increasing and reducing materials is more suitable for high-end manufacturing applications. On the one hand, it can realize the integrated molding of composite products with larger size, and the molding size of the five axis material addition and reduction machine (G40) can reach 3725 * 2500 * 1330mm, which can directly produce workpieces that meet the strength and size requirements without too much splicing and bonding. On the other hand, our integrated manufacturing process of material addition and reduction is incomparable with traditional 3D printing in terms of size accuracy and surface accuracy, Smaller deformation can realize the seamless assembly of all parts, and machining can make the surface smoother and more accurate.

3. Prints are strong and light, with excellent performance. Weight, strength, etc. are key factors to be considered when designing and manufacturing industrial products. It is difficult to give consideration to traditional manufacturing methods, but Piocut's solution can perfectly achieve high strength and maximum lightweight at the same time. We use fiber reinforced polymer composites to produce products, and the strength and stiffness can be significantly enhanced and improved. The compression resistance is excellent, and can be directly used in practical applications.

4. The production process is more simplified and the production cycle is greatly shortened. Piocreat integrates 3D printing and CNC processing on a single device, and directly enters the manufacturing of finished products from design. The whole process is fast and efficient, with environmental protection and material saving. Compared with the traditional manufacturing method, there is no need to open the mold, fewer processes and faster production speed, which are crucial for enterprises to quickly realize product upgrading and shorten the manufacturing process.

The integrated solution for the increase and decrease of large size composite products of Piocure is particularly suitable for the manufacturing of small batches of large size components and the iterative upgrading and research of products in special industries. It has a broad application prospect in military industry, aerospace, rail transit, new energy vehicles, shipbuilding and other industries. At present, it has been used in the interior trim parts, cover plates, etc. of various large aircraft, unmanned aerial vehicles, large size aircraft models, automobile shells and components, Manufacture of submarine and unmanned boat hull, ship spare parts and other parts.

With the rapid development of the manufacturing industry, the demand for large size and customized components is increasingly significant. The integration technology of large size composite materials will be an important development direction of manufacturing technology, and will bring more extensive application value to high-end manufacturing fields. Piocraet