3D printing in automobile industry: beyond imagination

In China and even in various countries around the world, the automotive industry - new models, accessories, consumables, spare parts, etc. - is definitely a field with strong demand. Because cars need regular maintenance and new models need to manufacture various parts, a new technology has emerged in the automotive industry, because the traditional manufacturing system of all related projects is difficult to deal with.

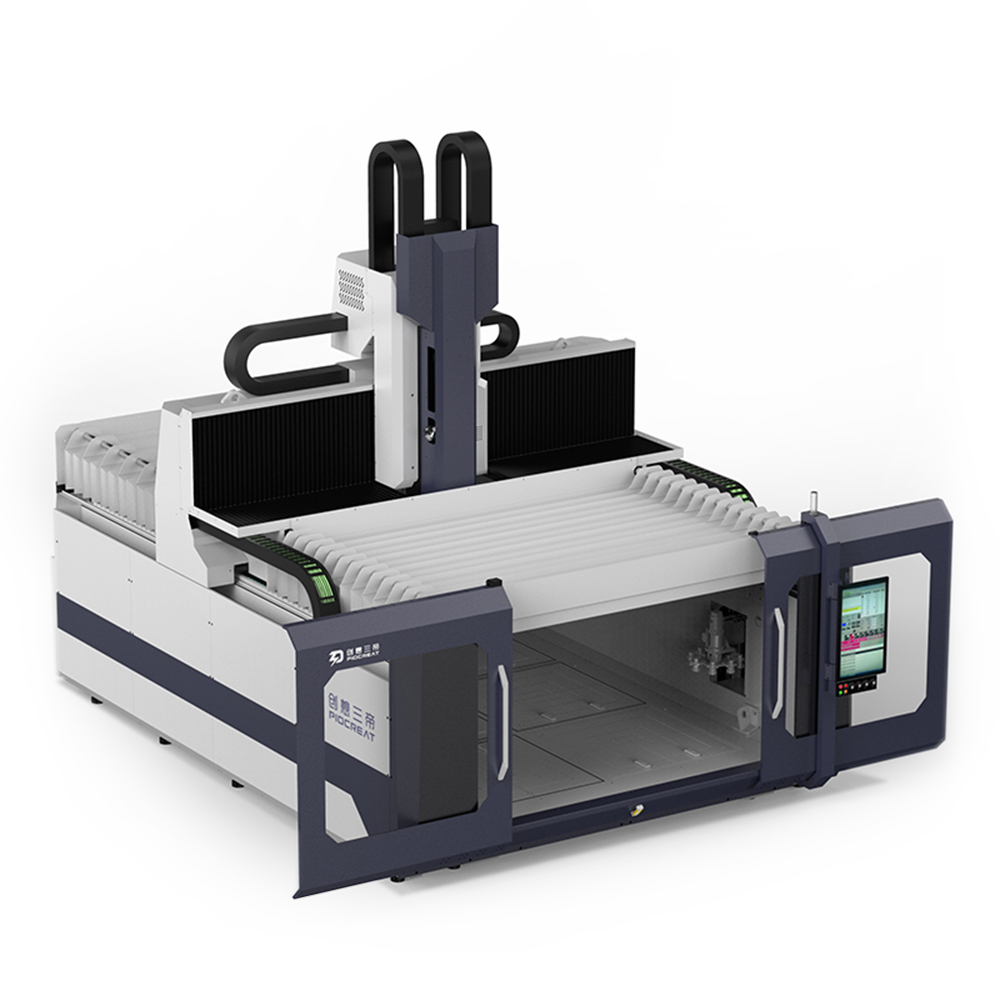

Specifically, 3D printing of functional parts is often used for new cars and other vehicles, including four-wheel vehicles, motorcycles or other vehicles. You want to print real size spare parts, accessories, prototypes or even 3D models. Piocreate can meet your needs through 3D printers of different sizes and features!

What can be 3D printed in the automotive field

The application of 3D printers in the automotive field can be said to be countless, suitable for all kinds of customers and partners. However, it is important to choose a 3D device that suits your needs. Therefore, here are some of the most popular materialized objects in the automotive industry:

Customized parts - the manufacturer can adapt the parts to the new model, and also provide special design for future drivers;

Prototypes - 3D printed models can be used as prototypes for new car series. This helps to diagnose any future design problems in order to resolve them before the final product appears;

Spare parts - The car needs regular maintenance and replacement of worn parts. Through 3D technology, you can copy and replace: fuel injectors, spark plugs, planetary gears, steering boxes, horns, various containers, filters, turbines, etc;

Tools - With the help of the 3D printer, you can also create the necessary tools to replace and repair car parts and fasteners.

Advantages of 3D application in automobile field:

cost reduction

Spare parts for new models can be copied in many ways. From a financial point of view, one of the most advantageous ways is to copy through 3D printing, whether you are implementing a large inventory of parts or a customized design for a smaller audience. The digital file of the product you are about to 3D print is enough to make the object "lifelike", replacing long and expensive production.

"Versatility" and customization

You can create 3D car parts (and more) in countless ways. For example, suppose you want to make a car handle. They can be produced on a large scale, with the same color, size and pattern, and are only suitable for one brand. On the other hand, with the help of the 3D printer, you can customize the handle design for different cars, use a rich palette, and the size depends on the project, even can be engraved.

Last but not least, because the field is vast, 3D printers can be at your side at any time, so it is important to choose the right device according to the objects to be created. For example, for large and super large parts, we recommend CNC equipment or industrial 3D printers; On the other hand, you need to make brackets for cups, handles, boxes or small objects, but for complex models, you can even turn to a hobby printer to make products at home.

Short production time

Making 3D printed parts can significantly reduce the waiting time and manufacturing of materials required for the automotive business. Since it requires less material consumption, it also helps to shorten production time. With a professional 3D printer, you can immediately make a large number of spare parts and so on!

Turn the project into reality immediately

Another benefit that the 3D printing project in the automotive field will bring is that the digital model will be immediately translated into reality, further shortening the time from the idea to the final result! Even if you start making real size small objects or car prototypes, your plan will use high-quality and sustainable materials for rapid prototyping!

Top automotive brands using 3D printing technology

BMW - Pre development, validation and testing of large and custom model vehicles using 3D technology;

Ford - use 3D technology to reduce mold costs, and speed up the production of spare parts and prototypes;

Volvo - use 3D printing for supply chain management of tools, spare parts, consumables, tools and other materialized objects;

General Motors - use 3D technology to make prototypes and prepare to expand production in other fields;

Porsche - 3D printing of major components and reshaping the supply chain for older models.

As you have noticed, there is a large demand for the automobile industry in China. If you want to develop business in this niche market and use 3D printers to manufacture spare parts, vehicle parts, accessories and other automotive items, you will certainly enjoy the success of your career as you wish in your life!