2023/03/10

Main Information

Brand:Piocreat

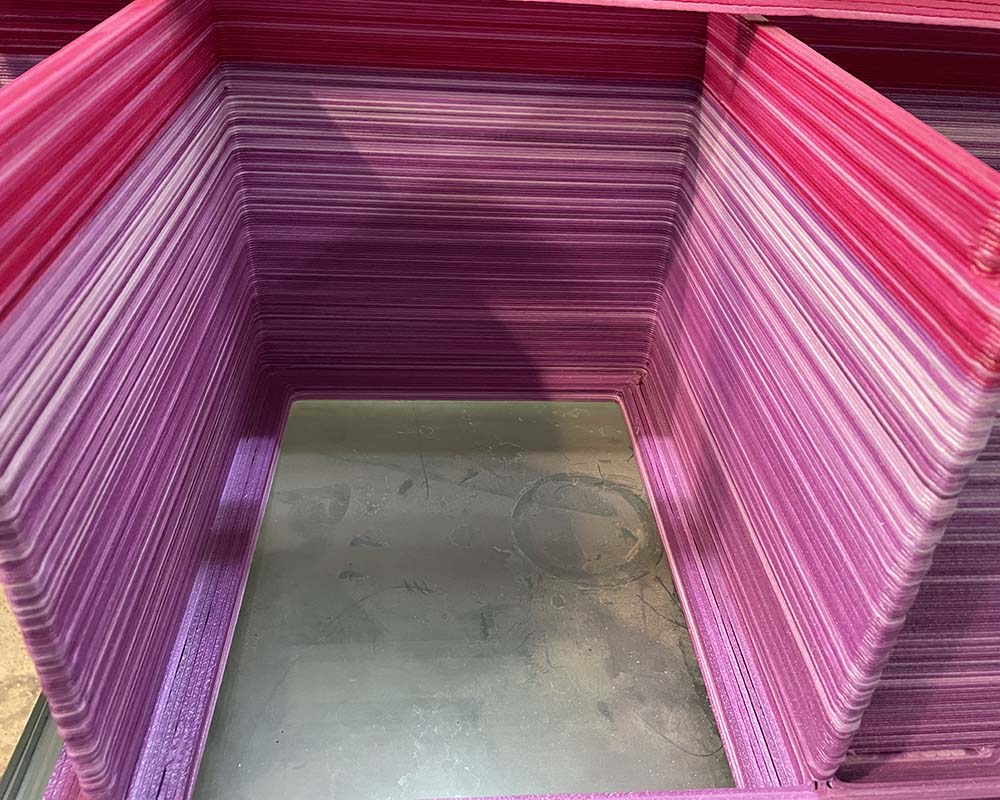

Printing machine: industrial 3d printers G12

Printing material: PETG+ Glass fiber particle+color pellet

Printing time: 10 days

Material cost: RMB1500

Model size: L1300*W800*H1000mm

MOdel name:Air purifying cylinder

Why Use Piocreat Printing Technology?

Compared with traditional FDM 3D Printing, PIOCREAT 3D Pellet 3D Printing Technology has the advantages of low cost and high efficiency. The fenders are printed with PETG modified material, which takes 7-10 days for Air purifying cylinder large batch production , weighs 10 kg, and costs about RMB 1000, But FDM 3D Printing needs take 20 days to printing,and costs about RMB 6000 for one larger industrial modle.

Air purifying cylinder Pellet 3d printer

Pellet 3d printer

Piocreat FGF pellet 3d printer G12 has a large printing area of 1.5 meters in length, width, and height,an extrusion head temperature of 450°C, Self deveped screw nozzle design with diameter 0.6-3mm,cossumables melt thoroughly and aqueeze out smoothly Printing Speed: 80~100mm/s.The automatic feeding technology has created excellent hardware conditions for pellet moulding of various materials,PLA、PETG、ABS、PC、PA、HDPE、TPU、EVA、PC+ABS、PA+Fiber、WPC、MQP-S+PA12、EVA based foam board.shenzhen piocreat 3d Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand piocreat 3D is a global industrial grade 3D printer brand.Hot Sale 1000000+sets, we have been best sold in such 192 +countries and regions as USA、Germany、UK etc, and cooperation agency.

At present, our 3D printing solutions have been applied to aerospace, automotive,petrochemical,medical, dental and electronics manufacturing.