Today's 3D printing technology has been very mature and applied to all walks of life. However, although 3D printers have existed in the domestic market for decades, there are still many people who are using or just know 3D printers, and do not understand the working principle and forming process of 3D printers. I just know that many three-dimensional objects can be printed with a 3D printer.

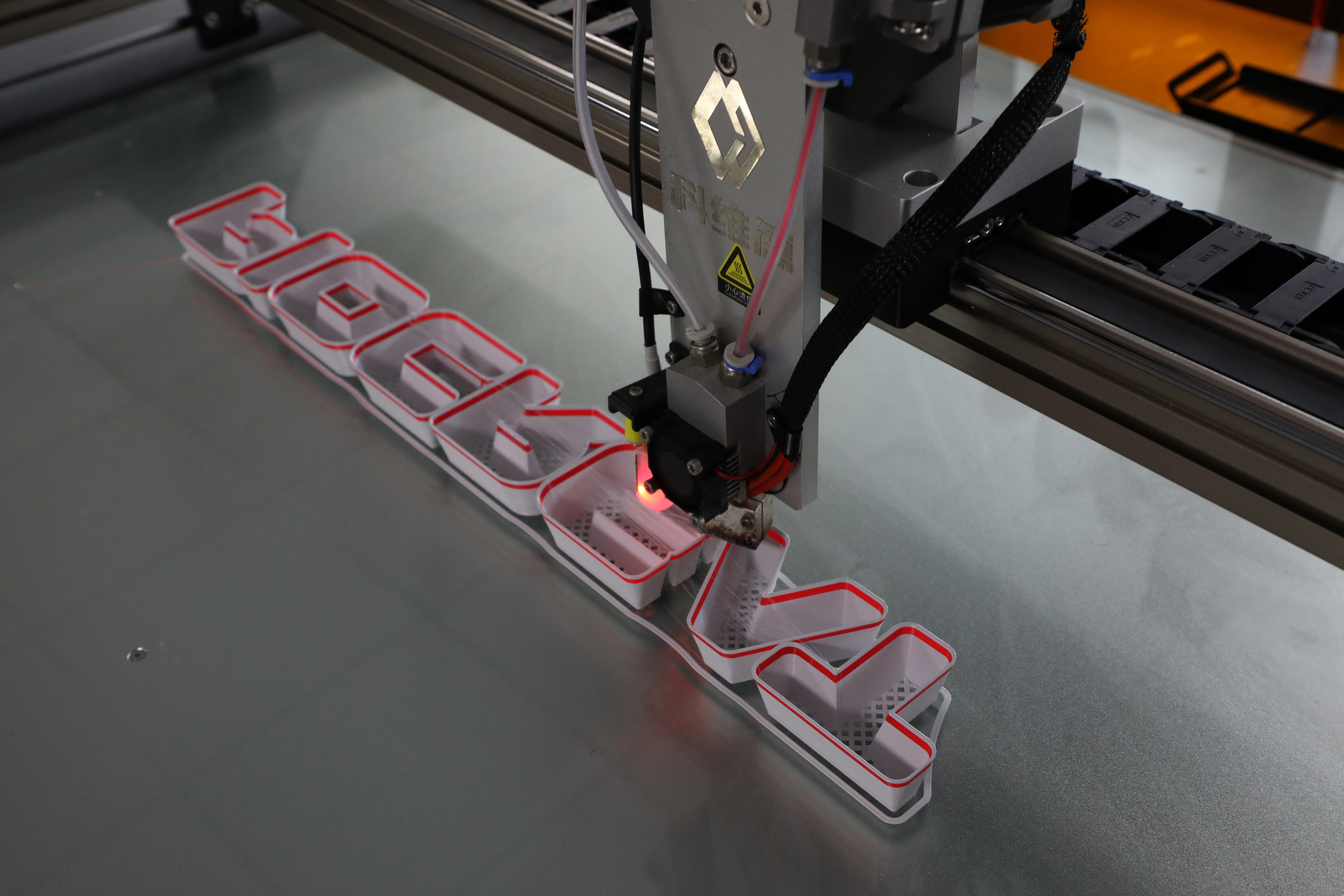

Especially in the advertising logo industry, many manufacturers have gradually abandoned the traditional production process and used 3D printers using FDM technology to print all kinds of channel letters, luminous channel letters and signs produced by this industry. So, what is the working principle of so many channel letters manufacturers using FDM technology 3D printers on the market? What kind of production process is it? Now let covid give you a brief explanation:

FDM (fused deposition modeling) is a melt lamination molding technology, sometimes called fuse deposition. Its working principle is to heat the hot-melt material to melt, and the filamentous material is extruded by the extruder with micro nozzle. The nozzle that can move along the x-axis direction, and the worktable is along the y-axis. After extruding the molten wire, it is immediately bonded with the previous layer of material, and then repeat these steps until the workpiece is formed.

And its production process is to pile up and form layer after layer under the control of the computer of the machine. The heating nozzle controlled by the machine can move in X-Y plane and Z direction according to the profile information. The filamentous thermoplastic material is sent to the nozzle through the wire feeding mechanism, heated to the molten state, and then selectively coated on the workbench. After rapid cooling, the cross-sectional profile is formed. After completing the section of one layer, increase the height of one layer of nozzle, and then apply the next layer. Repeat the above actions until a three-dimensional product is formed.