For more than two centuries, industrial factory production has performed well in four main areas: process repeatability, durability of production parts, production efficiency of work processes, and economic total operating costs. The factory workflow has been optimized to produce as many high-quality parts as possible at the lowest possible cost. Any new production method or workflow that seeks to be accepted along with standard processes must meet new requirements or improve these outdated elements in other ways.

Today's manufacturing industry is undergoing rapid transformation: some people call this process Industry 4.0. New market demands are pushing manufacturers to increase speed and flexibility. New business models require rapid response to customer needs and rapid design iterations. Manufacturers need shorter production cycles and faster product ecosystem evolution; they must build physical products at a digital speed.

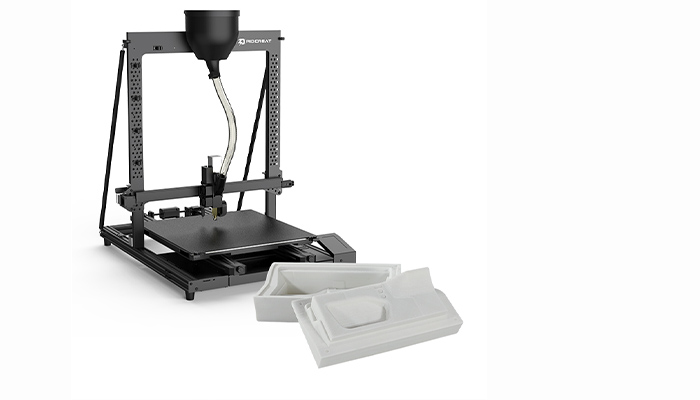

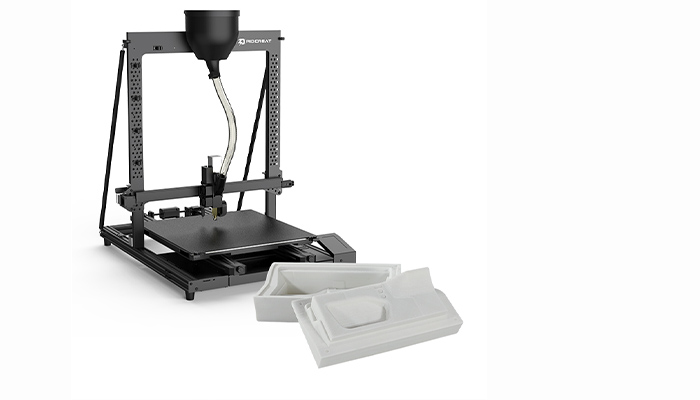

Scalable metal additive manufacturing for large seamless parts.

piocreat3d G5 is a metal 3D printing solution with optimized workflow, which can achieve large-scale scalability, repeatable quality parts, high throughput and low total operating costs, and can produce parts up to 500 mm x 500 mm x 500 mm.

Fortunately, for manufacturers facing these pressures, 3D printing technology has continuously improved its functions and has become a strategic asset for industrial factory production. New materials, new printing methods, new design capabilities and new workflows mean that digital manufacturing methods are possible. In the past 30 years, 3D printing has been the main research and development content of design review, prototype manufacturing, temporary disposable products or bypass manufacturing. Today, 3D printing is added to the factory floor and can be part of the mass production of the final product.

Parts manufactured using digital factory technology are more excellent in terms of repeatability and durability. They fulfill the promise of Industry 4.0 for products and processes, which is impossible to achieve with traditional methods. Advanced design algorithms support internal lattices instead of entities, which makes parts lighter but stronger. The injection molding industry can design conformal cooling molds or mass-produce new thermoplastic parts in hours instead of weeks. The digital casting process can quickly and flexibly create wax mold casting models and castings—low cost, no waiting for forming, no inherent defects of traditional casting, and direct metal printing.