Granular material 3D printer brings new possibilities for hand mold manufacturing

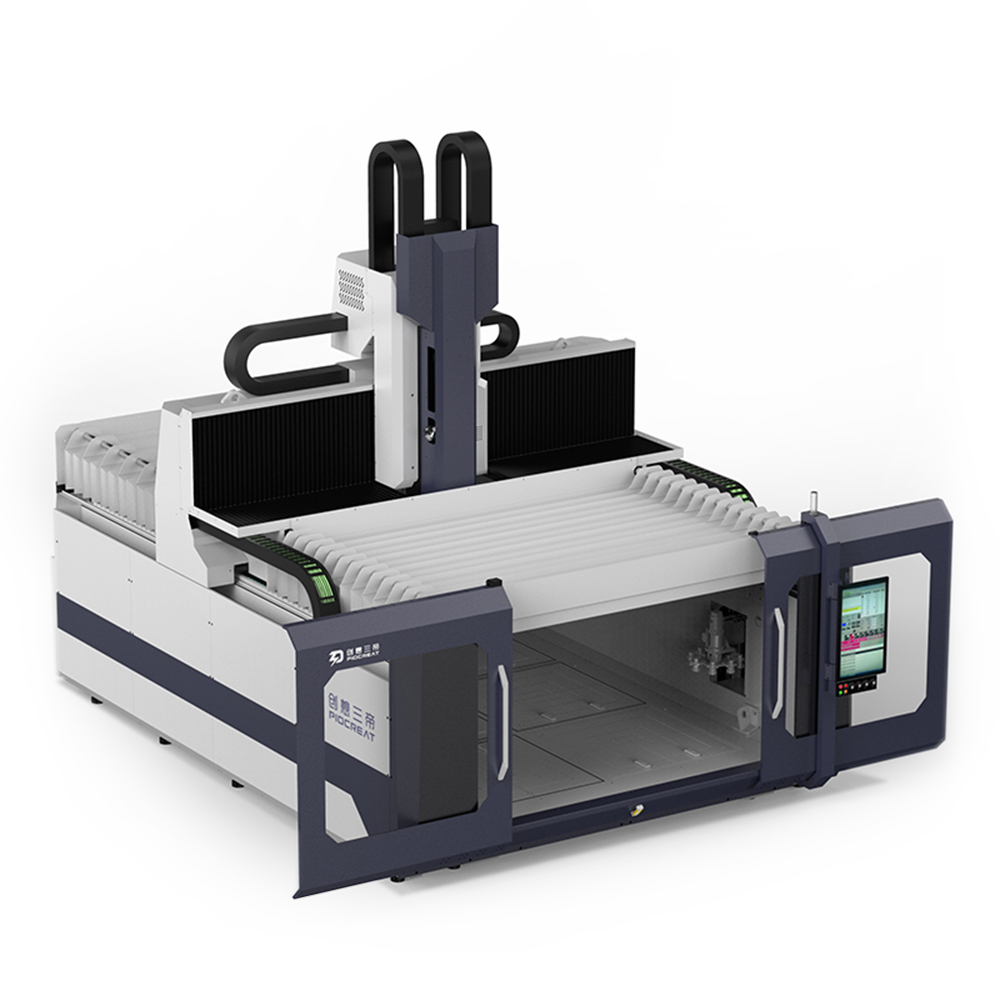

Hand board, a local industry in the manufacturing industry, is also called sample, verification, sample, equal scale model, etc. Generally speaking, the hand board is used for a small number of verification samples manufactured before product finalization. In recent years, with the upgrading and development of 3D printing technology, more and more hand board industries began to use

pellet 3D printers to make hand board models.

The main reason why 3D printing can develop so rapidly in the hand mold industry is the problem of labor. After entering the 21st century, the domestic labor cost is getting higher and higher. Taking 1997 as an example, the salary of workers who can skillfully control CNC handboard production that year is about 1000 yuan. After entering the 21st century, since 2010, the salary of handboard production workers has increased by almost 15% year by year. By 2020, the average wage of labor will reach 4000 to 5000. But it is not the biggest problem. Most of the time, the master who makes the hand board has the right to speak of the technology. Once the master feels that the salary is not high, the working environment is poor, and does not bring out several skilled apprentices, once he throws his hand, puts down the burden and leaves, it will be difficult for the factory to continue normal production. Therefore, in order to solve the problem of labor cost and loss, many hand mold manufacturers are looking for a new way out.

The main reason why 3D printing can develop so rapidly in the hand mold industry is the problem of labor. After entering the 21st century, the domestic labor cost is getting higher and higher. Taking 1997 as an example, the salary of workers who can skillfully control CNC handboard production that year is about 1000 yuan. After entering the 21st century, since 2010, the salary of handboard production workers has increased by almost 15% year by year. By 2020, the average wage of labor will reach 4000 to 5000. But it is not the biggest problem. Most of the time, the master who makes the hand board has the right to speak of the technology. Once the master feels that the salary is not high, the working environment is poor, and does not bring out several skilled apprentices, once he throws his hand, puts down the burden and leaves, it will be difficult for the factory to continue normal production. Therefore, in order to solve the problem of labor cost and loss, many hand mold manufacturers are looking for a new way out.

Compared with the traditional CNC manufacturing hand board, the biggest advantage of 3D printing lies in speed block and labor saving. Generally speaking, using CNC takes about a week to deliver, while using 3D printing can be shortened to 2 to 3 days, or even 24 hours. At the same time, if you need to make some structures with very high precision, twists and turns or hollowed out, pure curved surface and complex structure, some CNC can do it, but the time will be longer and the cost will be higher. 3D printing will have more advantages in this regard; The CNC structure with inverted buckle and inner space needs to be disassembled and assembled together. 3D printing is formed at one time without assembly; What's more, some very complex and fine models CNC can't do at all.

At present, the industries involved in 3D printing include aerospace, automobile, medical treatment, animation, construction, handicrafts and other industries. However, this does not mean that 3D printing can completely replace and subvert the previous traditional technology. Just like the production of hand molds, 3D printing cannot be completed for some models of transmission structure and action structure. It has to be done by CNC and manual work. The wear resistance of 3D printing is not enough and its performance is not comparable to that of CNC.

However, in any case, for the hand board mold manufacturing industry, the introduction and development of 3D printing technology is a new blood fusion for the hand board industry, which also makes the hand board industry burst out new vitality again.