Piocreat Launched G40 Large-scale Integrated Rocessing Center For Mold Material Increase And Decrease

In the past two years, China's 3D printing technology has accelerated the pace of innovation and progress in important fields of manufacturing industry, and has been more deeply and closely applied in aerospace, automobile, medical treatment, denture, mold, processing services and other industries. It has been comprehensively improved in terms of molding size, printing efficiency, printing quality, software system, product optimization, cost control, safety production and so on. With the rapid development of manufacturing industry, the industry's demand for product lightweight, customization and efficiency is increasing, which makes the application of carbon fiber and other composite products in aircraft, automobile and other large parts increasing. At the same time, it also puts forward higher requirements for the size, complexity and quality of product prototype.

It depends on the high quality of the traditional manufacturing mode, which is highly dependent on the upgrading of the quality of the mold. Therefore, the quality of the mold is highly dependent on the traditional and intelligent manufacturing mode, which is also highly dependent on the high quality of the mold. Considering the complex structure and customization of the mold, it is very attractive to make the mold by increasing or decreasing the material. G40 launched by Piocreat can effectively solve the pain points and difficulties in the process of upgrading enterprise intelligent manufacturing capacity, reduce costs, increase efficiency and improve production capacity through the integration technology of increasing and reducing materials.

Large gantry integrated processing center for increasing and decreasing materials-G40

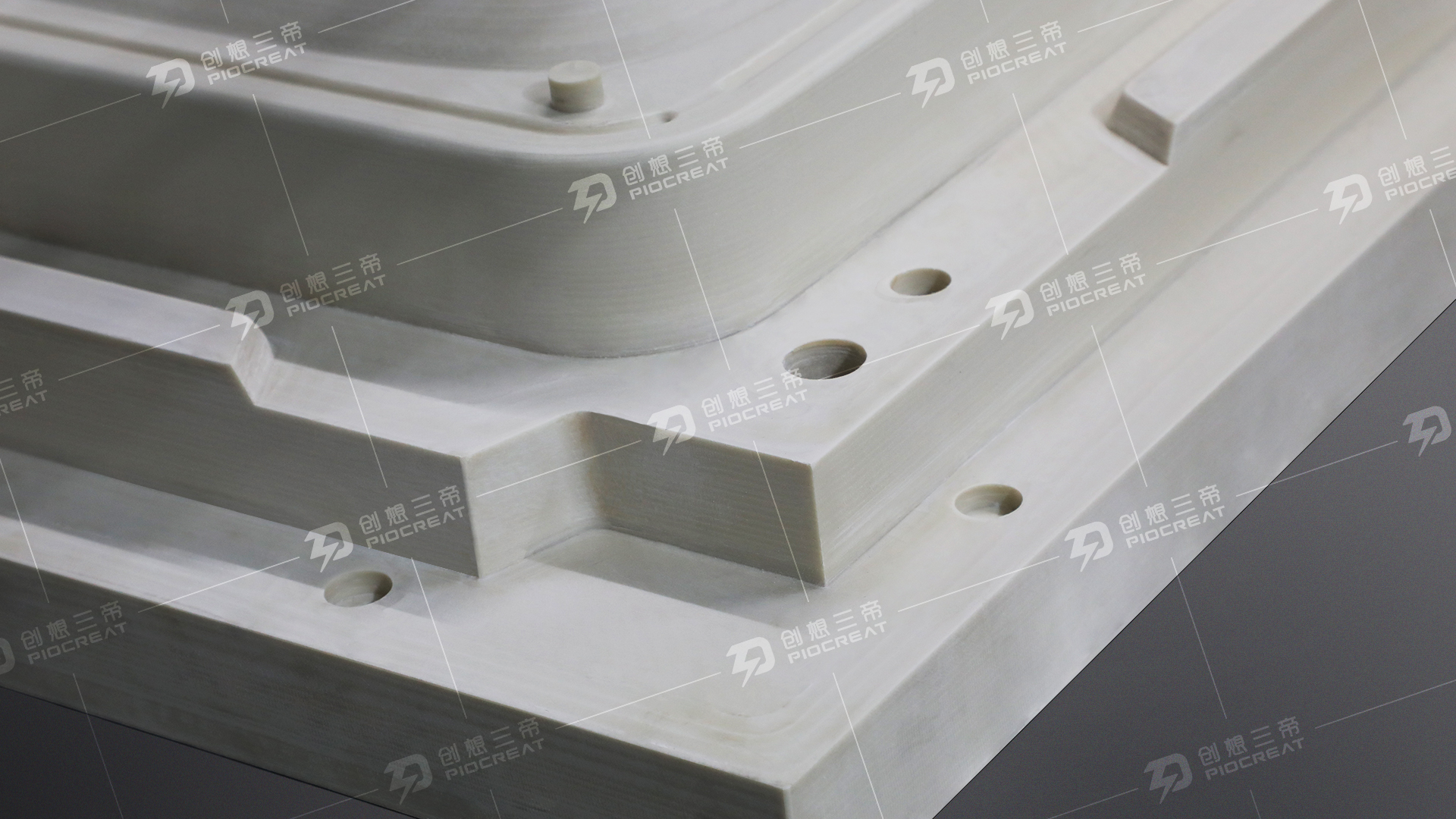

Piocreat G40 integrates the integrated manufacturing process of increasing and decreasing materials and polymer granular materials to create an integrated processing center of screw extrusion 3D printing and CNC five axis processing for the field of processing and manufacturing. From fine design, model optimization, to 3D printing and CNC post-processing, it provides a complete set of processing from design to finished products. It is suitable for manufacturing all kinds of normal temperature forming molds and molds. It can replace traditional gypsum molds, epoxy resin molds and wood molds. It can not only reduce cost, but also improve time efficiency and realize automatic production. It is an ideal solution for mold forming.

Integrated manufacturing and processing of super large materials

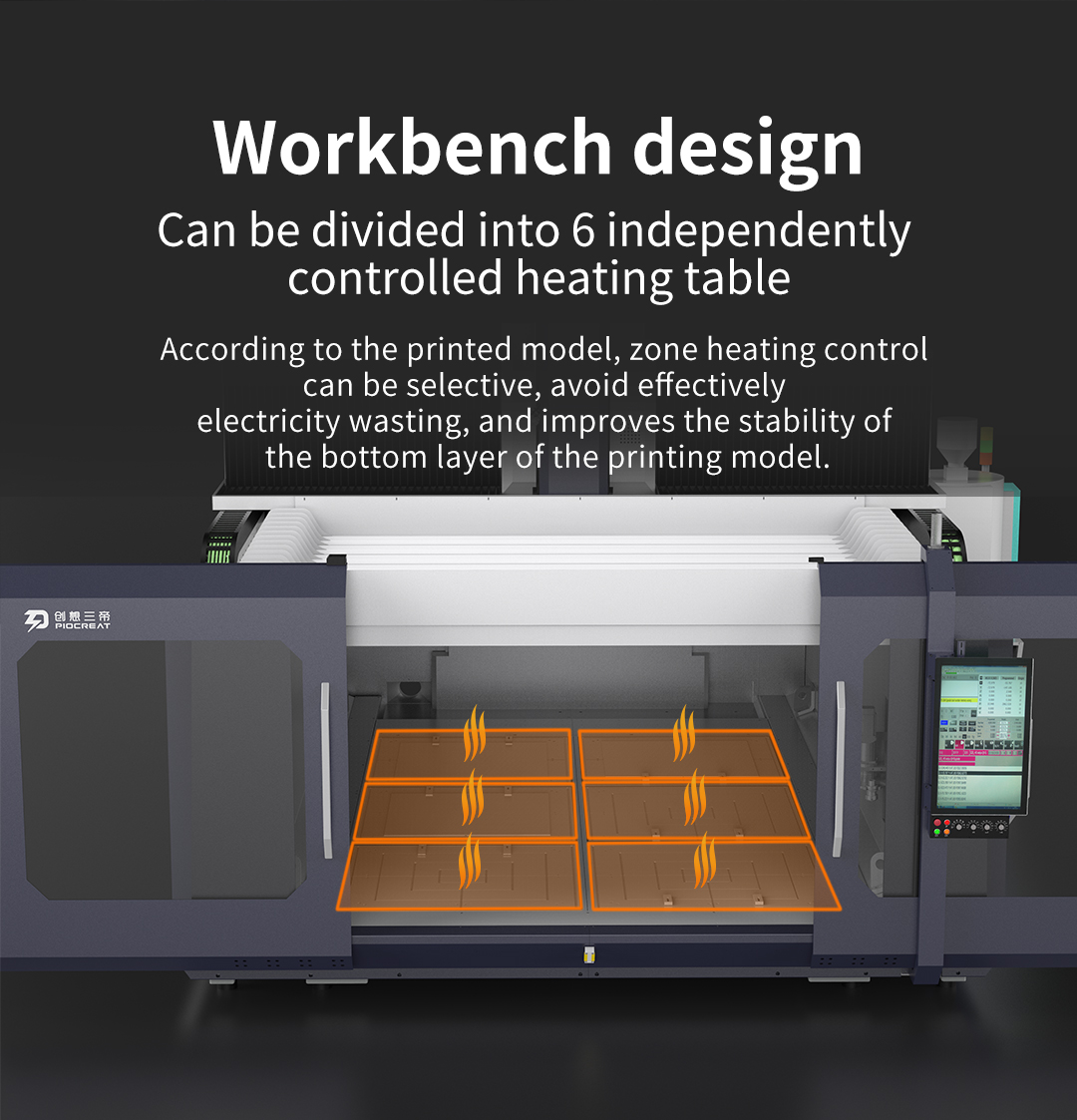

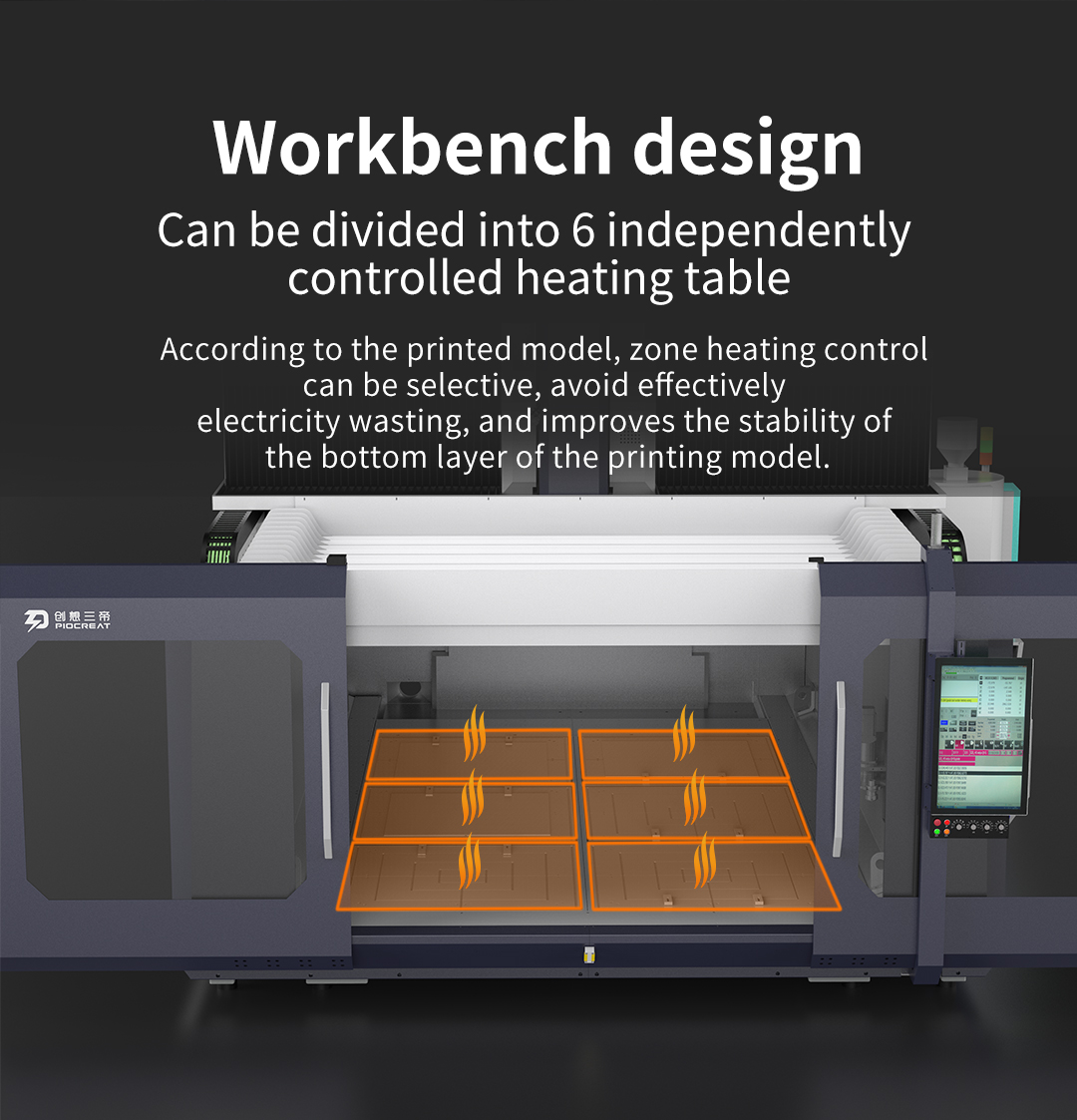

G40 is a large

industrial gantry 3D printer integrating 3D printing and five axis material reduction launched by Piocreat for intelligent manufacturing. The forming size is up to 3725mm x 2500 x 1330mm, and the extrusion capacity of the print head is up to 30kg / h. It can control the heating platform in different regions, and the printing controllability is better. It is not only suitable for manufacturing large molds, but also suitable for mass-produced parts and industrial tools.

The traditional die finishing methods mainly include fine turning, fine boring, reaming, hole grinding, electric machining and forming grinding. They are made of reduced materials. The materials used to process large workpieces are often more than those used to form workpieces, and the labor cost is high and the construction period is long. The integrated machining center of material increase and decrease of Piocreat large gantry adopts the combination of screw extrusion 3D printing and CNC five axis machining. Firstly, the workpiece close to the final size and contour is printed in 3D, and then the accurate model is made through CNC milling, which has low cost and high efficiency.

The manufacturing advantages of the integration of increasing and decreasing materials are obvious:

Flexible and efficient innovation

Compared with the production cycle of traditional aluminum steel molds for at least 1-2 months, the integrated manufacturing process of chuangxiang Sandi G40 can be put into production and use in only 1-2 weeks, which enables the production and manufacturing of molds to keep up with the changes of product design in time, fundamentally shortens the product design and R & D cycle of enterprises, and becomes a strong driving force for innovation in the industry.

Saving material, reducing cost, environmental protection and consumption

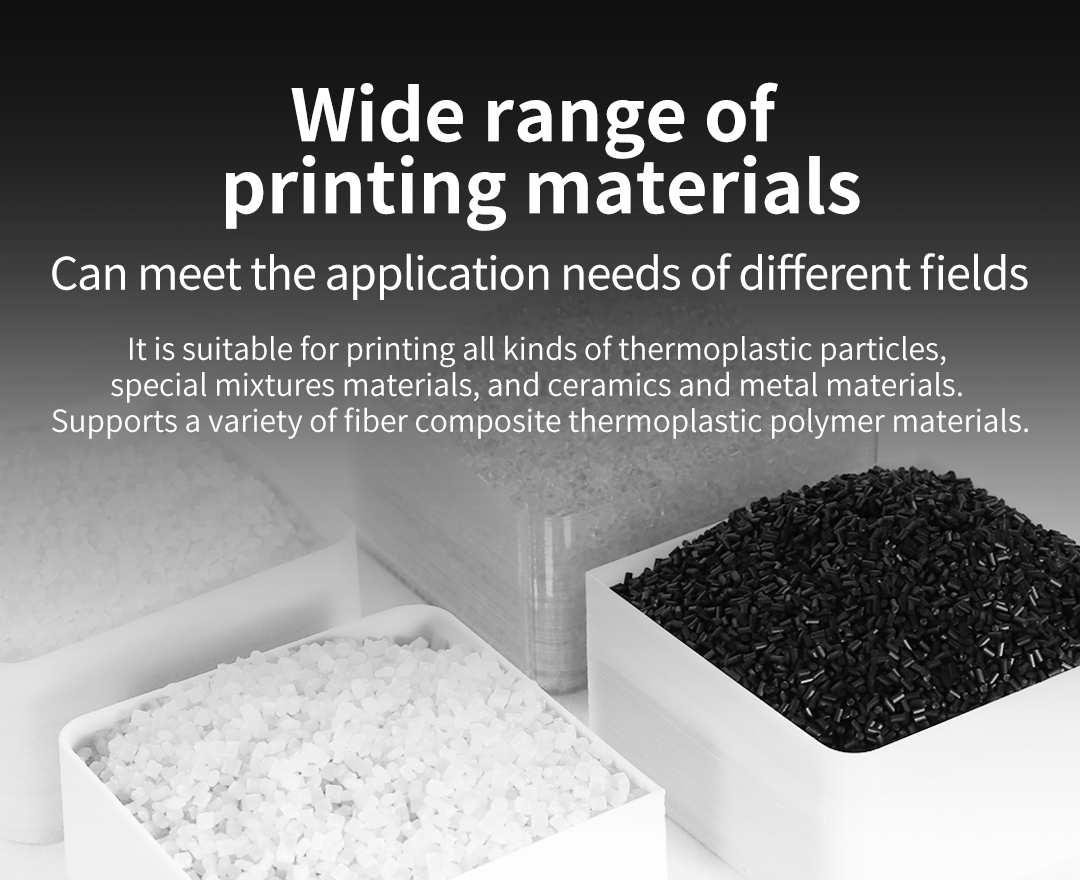

The manufacturing process of increasing and decreasing materials based on 3D printing rarely produces waste materials, and the material utilization rate is very high. G40 adopts ABS, PETG, TPU, PC, PLA and other granular materials, which is not only low cost, but also beneficial to environmental protection. In addition, the combination of 3D printing technology can simplify the mold manufacturing process, reduce the mold opening cost and labor cost. Moreover, in response to customized and lightweight customer needs, it can effectively reduce the cost of R & D and innovation.

Higher degree of customization

It is difficult to realize the complex structure workpiece by traditional technology, and the cost is high, such as hollowing out, curved surface and so on. 3D printing technology enables many complex structures to be realized, which can release the freedom of design to the greatest extent, realize the unrestricted design of product technology and form, so as to achieve the product design closest to the ideal state, so that enterprises can better and faster realize the production and manufacturing of various customized models.

Intelligent manufacturing drives industry change

The integrated manufacturing process of increasing and decreasing materials of chuangxiang three emperors puts the digital mold technology through the links of mold R & D, design and production, so as to improve the reliability of mold design, shorten the mold development cycle, realize automatic production, and further promote the application process of digital mold manufacturing technology in the industry.

Adaptability of various high performance composites

Chuangxiang Sandi G40 has a mature material supply system. At present, it has developed and tested a variety of thermoplastic polymer materials, such as abs-gf, petg-gf, TPU, PC, Pei, etc., which are specially customized for super large 3D printing. The materials have excellent mechanical properties and dimensional stability, and are widely used in the industry. At the same time, chuangxiang Sandi G40 uses granular material to replace the traditional wire rod, which also greatly reduces the material cost of the die.