Large Format 3D Printing + Post Processing Make Full Use Of The Advantages Of 3D Printing Of Pellets.

Large format 3D printing + post processing make full use of the advantages of 3D printing of granular materials.

Pellet based extrusion 3D printing offers many advantages, including achieving very high yields, reducing material costs, and providing new polymers in non silk mode. The cost of granular materials can also be 65-90% lower than that of filaments of the same plastic.

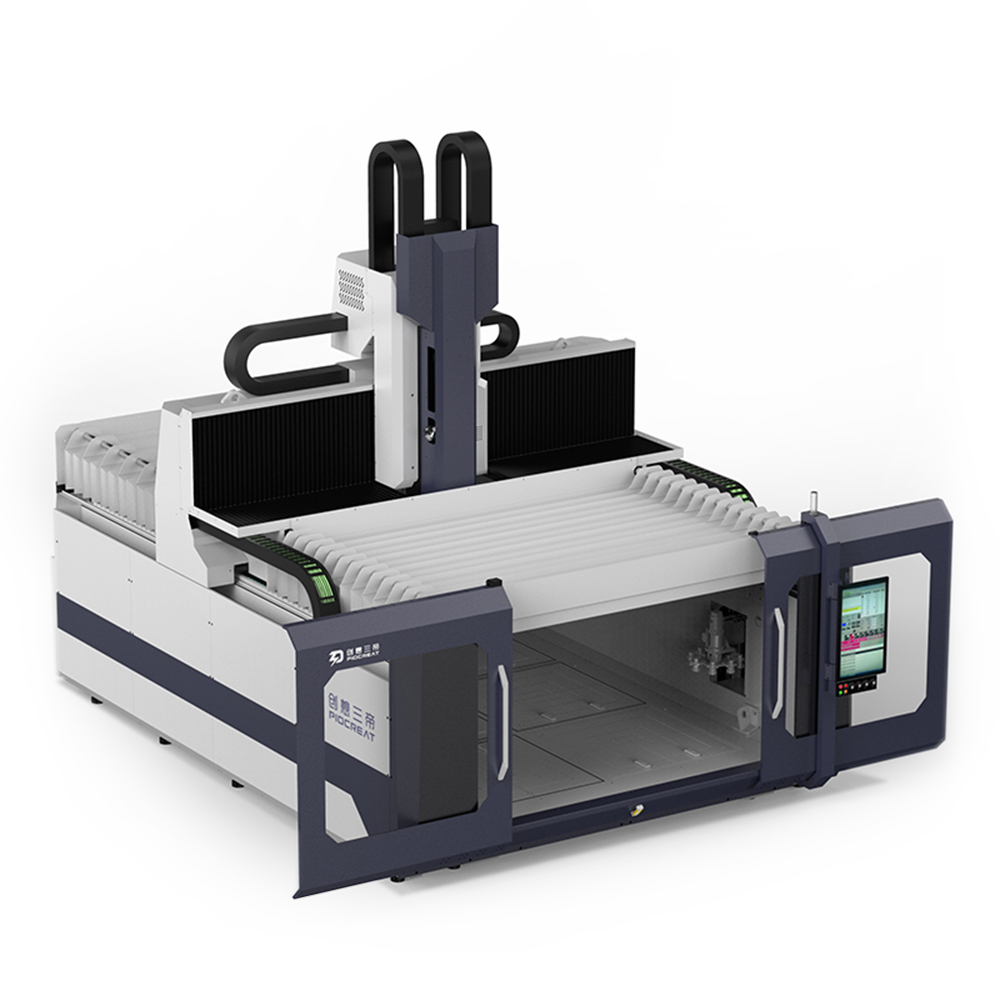

With a series of advantages provided by the G40 wood pellet 3D printer, customers will get faster printing speed and larger printing size. Due to the large nozzle in the particle extruder, the material extrusion speed is nearly 100 times higher than that of FDM 3D printer, and the printing speed is 200 times faster.

The combination of G40 pellet 3D printer and granule extruder is usually used for large-scale printing, such as 3D printing furniture. Due to the low material cost and fast printing time, the manufacturing of these objects is more economically feasible.

In addition, customers can create their own customized composites and material mixtures through the combination of different pellets. By easily adding various dyes, additives and reinforcing fibers to the mixture, customers can create customized composite plastics, and the waste can be mixed with the original pellets and reused.

Therefore, granular 3D printing has not only efficiency and cost advantages, but also environmental advantages. We can collect urban plastic waste for benches or sculptures in 3D printing parks. Now there are many companies selling recycled pellet fragments for granular 3D printing. Looking forward to the future, pioceat G40 envisages that everyone can chop up their own household pellet waste and use it as pellets in their own 3D printers, which is a very beautiful thing.

Realize large-scale industrial application

Pioceat's high flow rate particle extruder can extrude 30 kg of material per hour, which can print larger works in a shorter time. The extruder has six heating zones to ensure that the polymer is at a constant temperature at the end of extrusion, and the patented anti-seepage system can prevent leakage during movement. G40 pellet extruder can print any material currently produced on the market, including peek, ULTEM and PSU.

Particle based extrusion 3D printing G40 is disruptive. It achieves real high production, but most importantly, it reduces your material cost by 10 times and enables you to obtain new polymers without using filament as raw material.

At the same time, G40 is used for large-scale and independent additive manufacturing; It adopts self-developed slicing software, supports a variety of algorithms and slicing modes, and can provide process data adjusted by different parameters. Using advanced algorithms, Internet of things devices and cloud infrastructure to automate workflow, we aim to make 3D printing simple, intelligent and affordable.

The advanced tool path function of the software allows users to print complex geometric shapes without supports, thus reducing material waste, printing time and failure rate. Using tool paths, users can design and print the parts they want without any constraints or restrictions.