The field of 3D printing is expanding rapidly, and the application value of aerospace is increasingly prominent

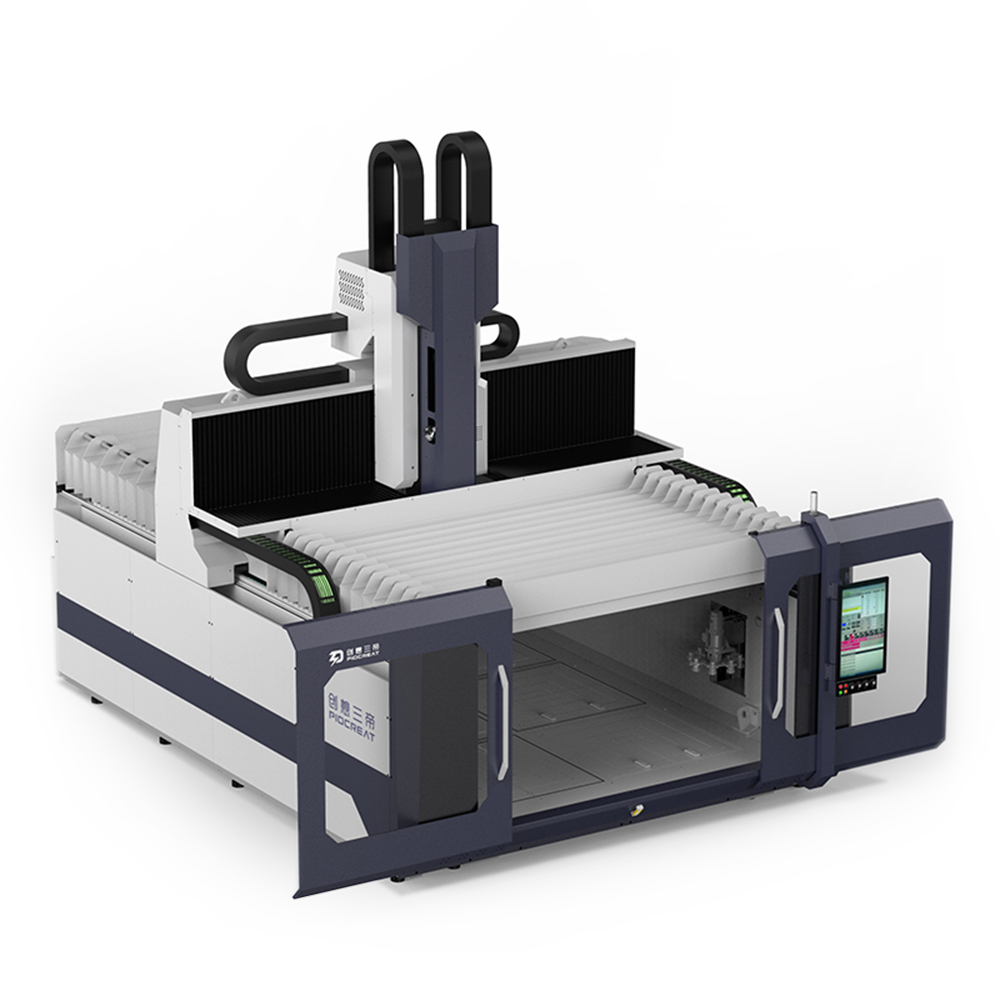

3D printing technology has the advantages of reducing costs, improving production efficiency, and improving the reliability and stability of parts. In recent years, the market demand has grown rapidly, especially for

industrial 3D printers.

Benefiting from the hot sales of the international 3D printer market, China has also actively developed relevant technologies to continuously improve the production technology level of 3D printers. Influenced by a series of favorable factors in the industry, such as policy support, continuous expansion of the market, and decline in production costs, 3D printing technology has rapidly entered the industrial era, and its commercial value in aerospace and other fields is increasingly apparent. It is of great significance to solve the shortage of related materials, reduce the number of parts, and improve the reliability of parts.

Recently, a "00 generation" college student in Nanjing used 3D printing technology to melt extrude and print the main structural parts of the rocket, and self-made the third generation reverse rocket model, effectively expanding the possibility of part design, greatly reducing the production cost, and making the workpiece convenient and fast. Another example is the large-scale use of 3D printing technology in the rocket of a foreign enterprise, which not only reduces the number of parts in traditional rocket manufacturing, but also improves the reliability and stability of parts, greatly improving its profit margin.

In addition, 3D printing technology also helps to successfully realize the 100 meter vertical recovery of China's liquid oxygen kerosene rocket. It is reported that in July 2021, Deep Blue Aerospace successfully achieved China's first vertical recovery test of liquid oxygen kerosene rocket, "Grasshopper Jump". In October, it successfully achieved China's first 100 meter vertical recovery test of liquid oxygen kerosene rocket. The engines used in both tests were made using 3D printing technology. The 3D printed rocket engine not only improves the quality stability and consistency of products, but also shortens the product development cycle, making the total cost of product development more competitive.

However, on the whole, compared with the countries that joined the R&D team of 3D printers earlier in foreign countries, China has started to research and develop 3D printing technology since the 1980s. At present, the production and manufacturing of 3D printers still face problems such as immature production technology, material quality and utilization rate restrictions, expensive prices, and the lack of core technology and cutting-edge talents is an important factor restricting the development of China's 3D printer industry. Therefore, relevant enterprises should also increase their R&D efforts, introduce technical talents, strengthen technical research, break down barriers to industrial development, and promote the overall level of domestic 3D printing technology.

Although 3D printing, as a way of additive manufacturing, is only a part of food, construction, aerospace and other processing and manufacturing industries, it cannot completely replace the traditional reduced material manufacturing or equal material manufacturing. However, it is true that 3D printing technology can reduce the number of parts, significantly shorten the product manufacturing process, improve manufacturing efficiency and product quality stability, reduce costs, etc., and accelerate the iterative speed of design manufacturing design of aerospace and other products.