Creality double hero: Exploring new ideas for future intelligent manufacturing based on the application trend of the 3D printing industry

At present, 3D printing technology has been recognized as one of the key core technologies of Intelligent Manufacturing in the future in the field of global science and technology. The in-depth application of 3D printing in various industries has become more and more mature. In China, chuangxiang has taken a firm step for seven years. With the continuous improvement of market influence and brand value, it has become a leading application enterprise in the global 3D printer industry. Continuous innovation, from point to area and creativity have realized the diversified development of the industry.

Never forget the original intention and deeply cultivate 3D printing technology to empower various industries

For seven years, Creality has been committed to promoting the marketization of 3D printers and providing efficient and practical 3D printing comprehensive solutions for dental medicine, industrial manufacturing, education and scientific research, culture, creation and art. At present, Creality has more than 500 R & D personnel and a total production site of nearly 50000 m2. It has advanced large-scale R & D center, 3D printing laboratory and chuangxiang Research Institute. It also cooperates with many colleges and universities to establish industry university research teaching practice bases, with complete R & D, manufacturing and after-sales systems and strong technical strength.

Global layout, providing digital dental full link services

Piocreat 3D has firmly grasped the high-speed track of digital dentistry, and has made full precipitation and accumulation in team talents and product R & D. Based on the team advantages, Creality has the composite R & D ability of hardware, algorithms and materials, and has obtained more than 500 patent applications, more than 100 invention licenses and many PCT international applications.

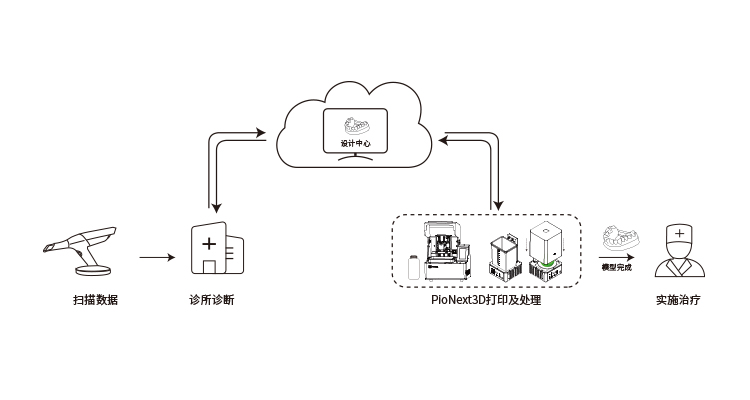

In terms of product structure, Piocreat 3D has a relatively complete dental digital solution and has been laid out in the global market. A one-stop digital dental service system was built. The system can connect the design platform pioneer box, Internet (Pionext official website) and equipment family (DJ89, D133 3D printer and UW-02 cleaning and curing all-in-one machine) to form a digital dental Internet of things, so as to realize the effective connection of users, equipment and articles.

3D printing enters the advertising field, and the traditional logo industry grabs new opportunities

The problems of advertising logo manufacturing industry have a long history and are complex. The traditional advertising industry has many problems, such as high equipment cost, complex process, high labor cost and complex personalized demand. The shrinking profit and intensified competition make the development of enterprises difficult. At the same time, they feel hesitant about investing in new technologies, new equipment and automation systems.

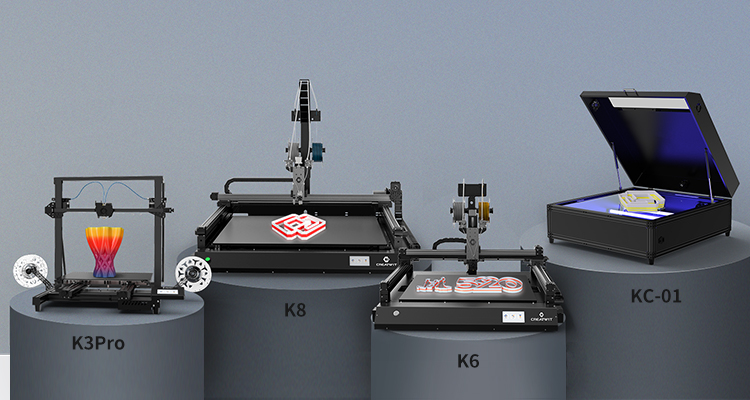

The K-series luminous word 3D printer independently developed by Piocreat has the ability to deal with this complex situation and help transform the production environment. 3D printing technology can solve complex manufacturing problems, integrate networks and physical systems to achieve optimal output, and find and realize value through data interpretation. At present, K series products have been widely used in the advertising field, with more than 1000 cooperative customers, which has won the full recognition of the market.

3D printing of self-developed granular materials creates unlimited possibilities

In the field of industrial manufacturing, how to reduce production costs and shorten product design and development cycle is a major pain point in the development of manufacturing industry. 3D printing technology can directly manufacture design prototypes in a short time, so that developers can quickly verify and optimize products. Especially in some small batch non general parts, tooling and fixtures, 3D printing technology has brought new ideas to the traditional manufacturing industry with its ultra-high manufacturing efficiency and very low production cost.

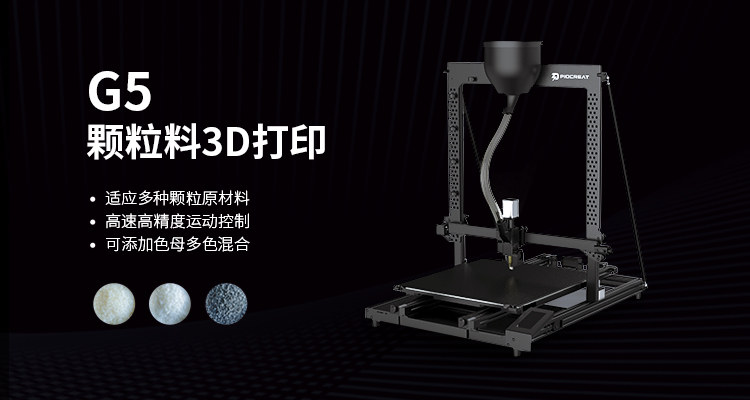

The pellets 3D printer G5 independently developed by Piocreat adopts granular material instead of traditional wire, and is equipped with screw structure print head design, which improves the printing efficiency by 5-10 times. Low cost and high efficiency 3D printing technology meets users' demands for high-speed, high-precision and multi-material 3D printing. At present, G5 has been deeply applied in teaching and scientific research, abrasives, sculpture and other fields. In the future, Piocreat will explore new possibilities in more industries based on 3D printing of granular materials.