3D printing is a rapid prototyping technology. It is a technology based on digital model files. By printing layer by layer, objects are constructed using pellets, plastic or powder metal and other adhesive materials. 3D printers usually use digital technology and material printers. The following is what 3D printing technology can use.

In the future, 3D printers can be extended to new applications

1、 Used in handicraft industry

1. Improve original design: integrate elements into original product design, quickly obtain design elements through three-dimensional digital means, and save development time.

2. Improve the sculpture speed and reduce the cost: 3D digitization can enlarge and reduce the product, and then print out 3D, so as to quickly copy different sizes.

3. Improve sculpture quality: through computer CG technology and designing sculpture products through computer CG, product design and sculpture can be completed more effectively. The sample passing rate of Japanese and Disney products exceeds 90%.

2、 Shoe factory industry

The combination rate of sole and upper developed by 3D technology can reach almost 100%. 3D printing is a special material accumulation process. The utilization rate of raw materials is 100%. Just operate the computer. There is no other manual assistance in the production process, which also shows the obvious advantage of saving labor cost.

3、 Automobile industry

3D printing can be extended to new applications and will play a very important role in automobile and other industries. 3D printing plays an important role in model printing and parts printing of automotive products.

4、 Sand table model industry

3D printing sand table model has incomparable advantages over traditional manufacturing technology. It can not only make a scaled down three-dimensional solid model quickly and accurately, but also meet the personalized needs. Customization enables sand table production to a broader space. 3D printing sand table model based on digital manufacturing technology. 3D printing combines accurate virtual 3D model and real physical objects, which greatly reduces the threshold and time cycle of sand table manufacturing.

5、 Aviation Industry

As a typical representative technology in the manufacturing field of the third industrial revolution, 3D printing has attracted extensive attention from all walks of life.

With the help of 3D printing technology and other information technologies, it will take the aviation industry at least three years to develop a new fighter. In addition,

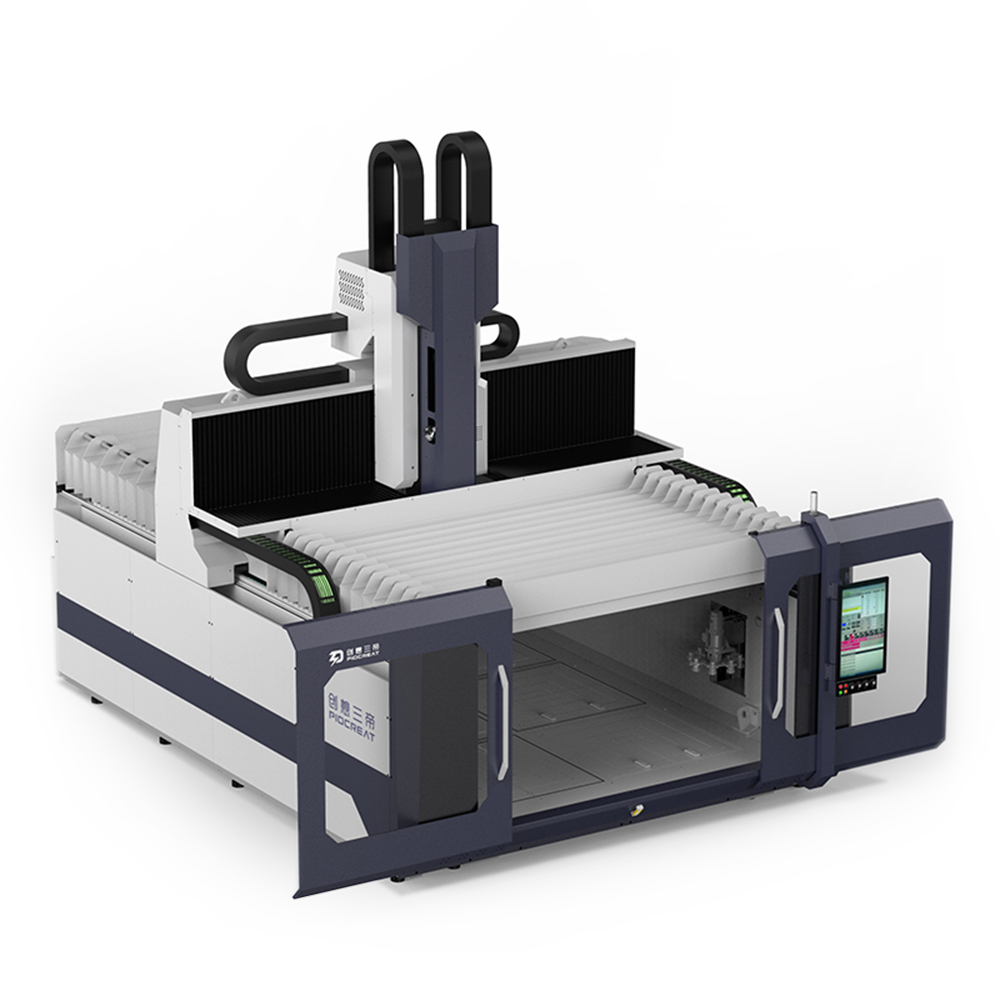

pellet 3D printer will shine brightly in the aerospace field, provide strong technical support for the manufacturing of national defense equipment, have the characteristics of high flexibility, high performance and flexible manufacturing, and free rapid prototyping of complex parts. At present, piocreat has launched several types of pellet 3D printers, which can meet the printing needs of different industries and sizes. Moreover, our large-size integrated machining center

G40 can not only carry out 3D printers, but also milling.

The above is piocreat's view that 3D printing can be extended to new applications in the future. I hope the above introduction can help you.