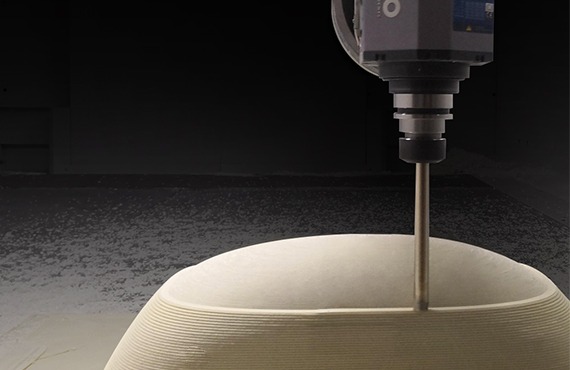

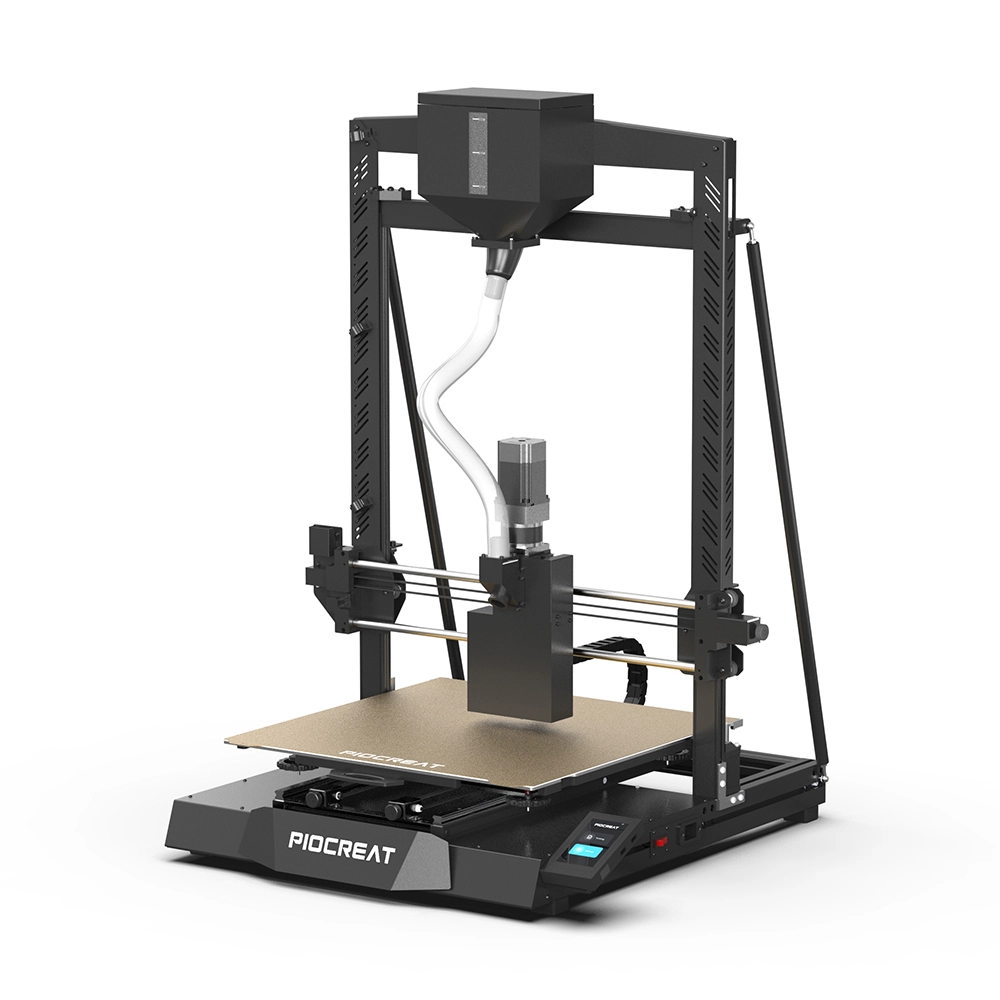

The G40 pellet extruder 3d printer merges large-scale, high-speed 3D printing with CNC five-axis manufacturing, excelling in thermoplastic extrusion. It’s a combined additive and subtractive machine that 3D prints workpieces nearly to final size then mills them to precise specifications. This enhances production speed, cuts costs, and optimizes material use. Ideal for large patterns, molds, batches, and prototypes, it’s widely used in manufacturing, automotive, aerospace, and marine industries.

With its ability to heat up to 450℃, the G40 enables the processing of a vast array of thermoplastics and composites, including PLA, PETG, ABS, PC, PA and other composite materials. This flexibility ensures that users can select the ideal material for each project, tailoring their approach to leverage specific material properties for better outcomes.

The G40 advances extrusion efficiency with its high-flow, 3-8mm screw nozzles, achieving high flow rates (up to 25kg/hr) and maintaining quality. Its gantry precision is ±0.02mm/1000mm. The printer impressively runs at 10m/min and processes at 15m/min, ideal for additive and subtractive manufacturing, highlighting its rapid and reliable production capabilities.

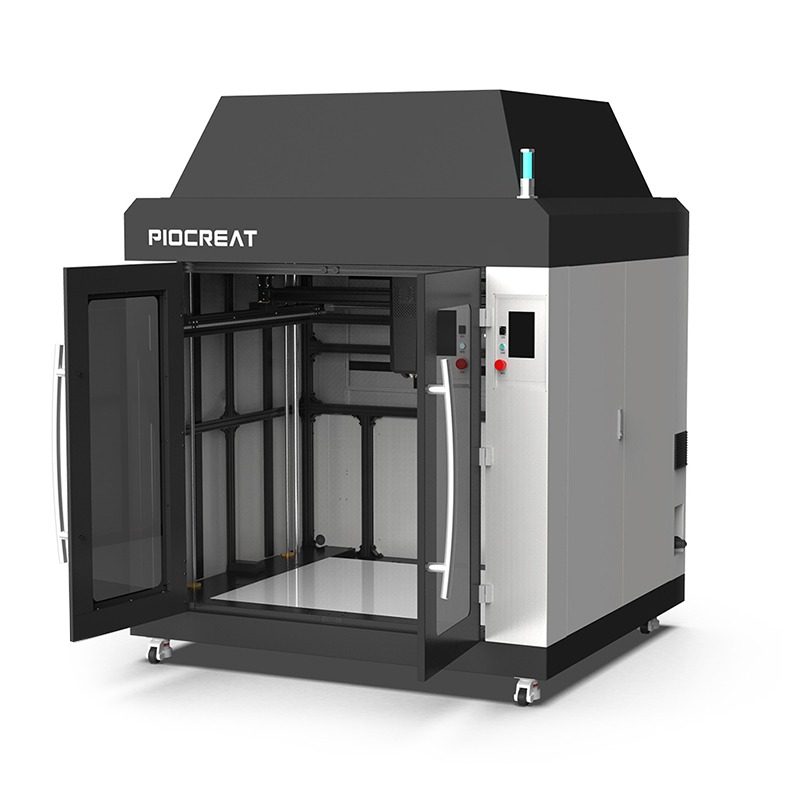

The G40 Pellet 3D Printer boasts an impressive large working space of 3725×2500×1330mm, providing ample room for the production of various large-scale components. This spacious build area is ideal for the creation of expansive patterns, full-scale molds, and substantial functional prototypes.

The G40 boasts an 8.5KW/24000 hvct and advanced CNC five-axis head for high precision. Its A axis offers +120° and the C axis +320° rotation, ensuring flexibility and top performance. The machine excels in processing thermoplastics, carbon fiber, and engineering-grade polymers with outstanding accuracy and ease.

Pellet extrusion 3D printing offers significant savings, cutting costs up to 10X compared to traditional filament-based methods.

Enjoy speeds up to 10X faster than conventional filament extrusion 3D printing, drastically reducing project lead times.

Use original materials for optimal material properties, ensuring enhanced performance of printed components through superior quality.

Our 3D printing innovation uses pellets and shredded recycled plastic for sustainable, eco-friendly additive manufacturing alternatives.

| G40 Pellet 3D Printer Parameters | |

|---|---|

| Molding technology | FGF Fused Granulate Fabrication |

| Built Volume | 3725×2500×1330mm |

| Machine Size | 5962×4220×4800mm |

| Discharge structure | Screw extrusion |

| Nozzle number | Single nozzl |

| Nozzle Tempature | ≤450°C |

| Maximum workbench heating | ≤120°C |

| Particles diameter | 2-5mm |

| 3-Axis positioning accuracy | ±0.1mm/m |

| Particle diameterr | 2-5mm |

| Print layer thickness | 0.2-1.0mm |

| Nozzle diameter | 3-8mm |

| Flow Rates | 25kg/h |

| Rated Power | 65KW |

| Files Format | STL/OBJ/AMF |

| Transfer method | U disk / WIFI printing |

| Slicing software | Piocreat Slicer/Cura/Simplify3D |

| Warranty | 12 months manufacturer's warranty |

| Technical Support | Unlimited lifetime technical support |

| G40 CNC machining parameters | |

|---|---|

| Processing size | 3400×2500×1330mm |

| Processing speed | 20m/min |

| Spindle power | 8.5KW |

| Processing mode | Five axis |

Cut your material costs by more than 60% by printing with Plastic pellets and recycled plastics instead of filament.

Various types of nozzles 0.4,0.8, 1.0, 1.5, 2.0, 3.0, 4.0,etc.

Independent research and development, multi-point detection, intelligent compensation.

Maximum temperature 450°C, Consumables melt thoroughly and extrude smoothly.

3D printer insulation cover, Thermal insulation, constant temperature printing.

Heating up quickly,reducing waiting time for printing. The platform is easy to put and take,can be bent,easy to take the mold.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.