With the transfer of

3D printers from the R & D workshop to the processing workshop, the emerging question is "will 3D printing replace CNC processing?" The short answer is no, because it does not need, or they can coexist in another way.

3D printing and CNC processing both occupy a place in the manufacturing industry. In fact, they are friends rather than rivals. In short, both are useful, and they are suitable for different jobs. Then we need to know how to use them together to maximize the processing advantage.

The main difference between the two is that 3D printing is an additive process, while CNC is a subtractive process. 3D printing builds parts layer by layer from scratch. CNC technology starts from removing the material until the desired shape is obtained.

Their respective advantages are as follows:

● 3D printing advantages:

1. freedom of design - geometric shapes that cannot be achieved by traditional manufacturing methods (i.e. more freedom of complexity) can be realized, and complex molds are not required before manufacturing.

2. parts can be combined - components requiring multiple parts and manufacturing / connection methods can be printed as a single piece.

3. lightweight - 3D printing allows materials to be placed in the most important place. You can easily create voids, cells, or lattices without creating additional steps or removing them.

4. fast speed - the time from 3D model file to final part is the shortest. Multiple changes can be made instantly.

5. less programming time - compared with CNC machining, 3D printing requires less user interaction to create machine motion paths. In some cases, it can be a simple button, but in other cases, it may require more knowledge, such as creating the best support structure for SLA or DMLS.

6. waste reduction, environmental protection and sustainability - you only use the materials required to produce parts. Even if there is a supporting structure, the material consumed is usually much less than the reduced material. In some color increasing manufacturing processes, the remaining materials can be reused.

● CNC processing advantages:

1. wide range of materials - the range of materials available for CNC is very wide, including metal, plastic and wood. In general, it is not common for 3D printers in mass production to have multiple or multiple material options. Even if the number is limited, sometimes the conversion can be expensive and time-consuming.

2. product tolerance - CNC machining can process parts to strict tolerance; Typically 10 to 100 times better than 3D printing.

3. high surface finish, i.e. low roughness - the surface finish of CNC machine tool parts is usually very good, depending on the part geometry, tool geometry and processing time.

4. high indirect acceptance in the industry: due to the existing part certification and CNC manufacturing methods, many industries accept CNC processing parts.

5. open architecture - generally, users of CNC technology purchase their tools and materials from third-party suppliers and enjoy multiple sources of these projects; However, 3D printer users often have to purchase their consumables from a single source. In most cases, this source is a 3D printer manufacturer.

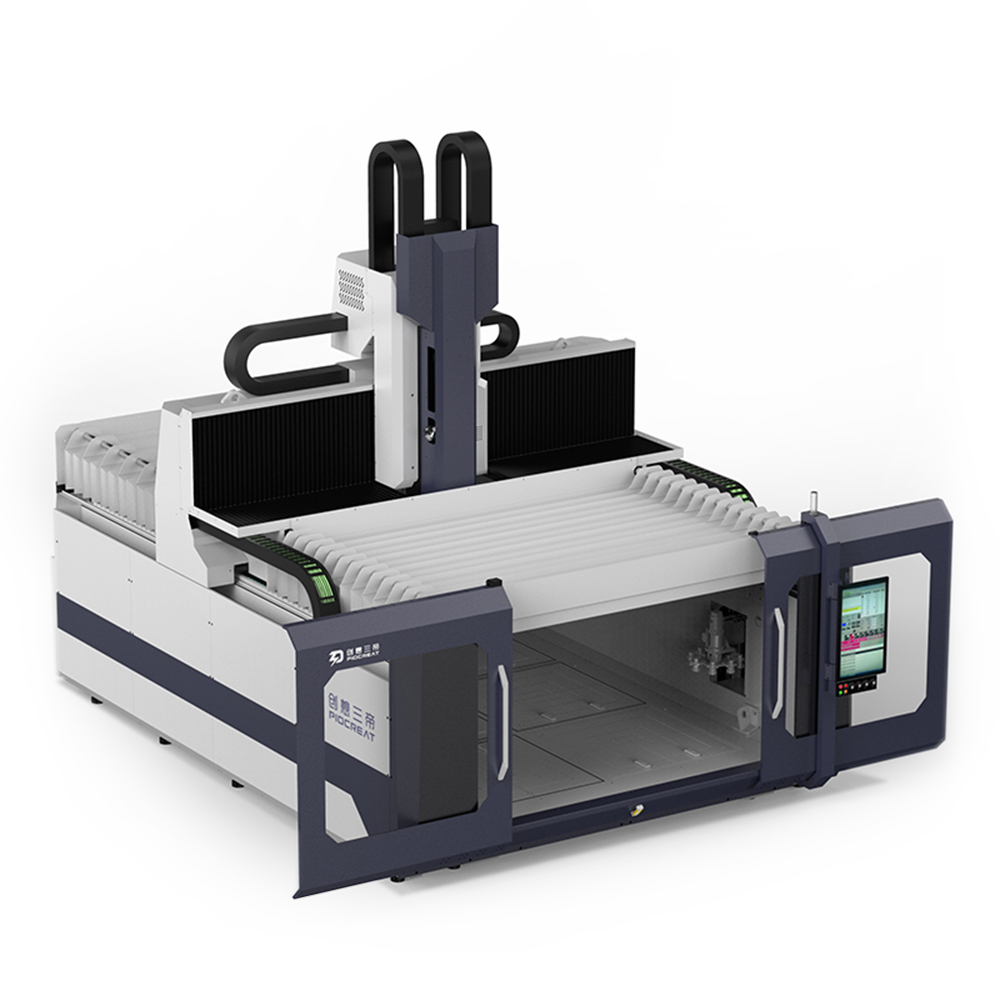

However, the emergence of

G40 large-scale integrated machining center for adding and removing materials has closely linked 3D printing and CNC. G40 can not only realize 3D printing, but also milling after printing. Because it is processed on the basis of 3D printing model, it can reduce material consumption and waste, thus reducing production costs.