The most eye-catching: the application of 3D printing technology in the dental field

At present, the rapidly developing 3D printing technology has been applied to many industries, of which the application in the dental industry is the most eye-catching. The 3D printing technology is naturally matched with the dental industry, and its application in the oral cavity is also constantly breaking through. The deepening of these applications realizes personalized customization, optimizes the medical process, and reduces pain. Prismlab, as a company focusing on the research and development of 3D printing technology, has long had a layout in the dental industry. The following is a brief introduction to the main applications of 3D printing technology in the dental industry based on prismlab's experience and market cognition in the dental industry over the years.

Compared with biological 3D printing, the principle of non biological 3D printing is relatively simple and the required materials are relatively easy to obtain, so it has been widely used in the medical field. And dentistry is one of the most promising industries in non biological 3D printing.

3D printing technology has obvious advantages in dentistry

First of all, based on the difference of tooth characteristics of each patient in the dental industry, the 3D data generated are different, and the application of 3D printing technology can achieve personalized production. Secondly, the structure of human teeth is relatively complex. Traditional manual work will lead to deviation in the accuracy of dental medical products, resulting in discomfort of patients. 3D printing technology meets the needs of precision, complexity and customization of dentistry. Finally, dental patients always hope to get rapid and effective treatment. Traditional processing methods are slow, and 3D printing technology can accelerate the progress of the treatment process.

The application of 3D printing technology in the dental industry mainly includes orthodontics, dental implants and restorations and removable dentures. Dentistry is the most promising medical field of 3D printing technology that can be applied on a large scale.

Dental orthodontics

The application of 3D printing technology in orthodontics is mainly lingual orthodontics and invisible transparent orthodontics. The 3D printing technology of lingual orthosis is mostly SLM (selective laser melting) technology. Compared with the traditional investment casting method, the metal lingual orthosis printed by SLM technology can realize the direct molding of personalized brackets and avoid casting defects such as cavities and cavities. The invisible transparent correctors are mostly SLA (light curing molding) technology, DLP (digital light processing) technology and LCD (laser clamping deposition). Invisible orthodontic technology is the first 3D printing commodity to realize mass production in the world. 3D printing technology can realize mass customized production of dental models at different orthodontic stages.

The production process of the whole invisible appliance is roughly divided into "impression - scanning - 3D modeling - digital analog correction design - 3D printing dental model - appliance processing - cleaning and disinfection". In the whole process, 3D printing mainly undertakes the function of mass customization of dental models in different correction stages. After the tooth model is made, the transparent film is wrapped on the model by the thermoplastic molding process, so as to make the invisible appliance suitable for the patient. Through the analysis of the patient's oral data, professionals will conduct tooth arrangement design in combination with software, for example, each tooth moves 0.2-0.3 mm each time, or twists 3-5 degrees, so as to obtain the oral model data at different correction stages, and then print them in batch by using 3D printing technology.

Usually, a patient needs to replace about 30-40 pairs of invisible appliances to achieve the correction effect through the continuous tilt force on the teeth. 30-40 pairs of invisible appliances means that 30-40 orthodontic models need to be printed, and there are only very small differences between each model. If the traditional processing method is adopted, it is impossible to tailor and mass produce the correction model for patients in a short time. As a digital molding technology, 3D printing can transform any digital design into a real object, and the light curing 3D printing technology just meets the two conditions of personalization and mass production.

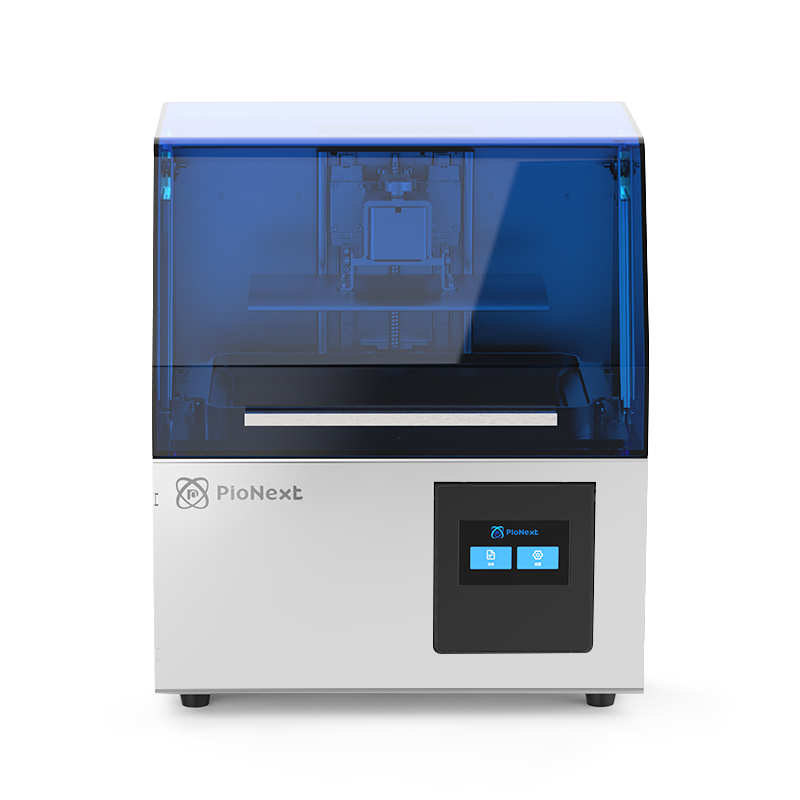

Invisible correction is a kind of digital medical treatment. How to realize accurate "digitization"? Software and device support are indispensable. Unlike traditional correction methods, invisible correction has a process of digital transformation. No matter from the perspective of cost, accuracy, efficiency, stability and safety, 3D printers using light curing technology are the best choice.