2022/09/09

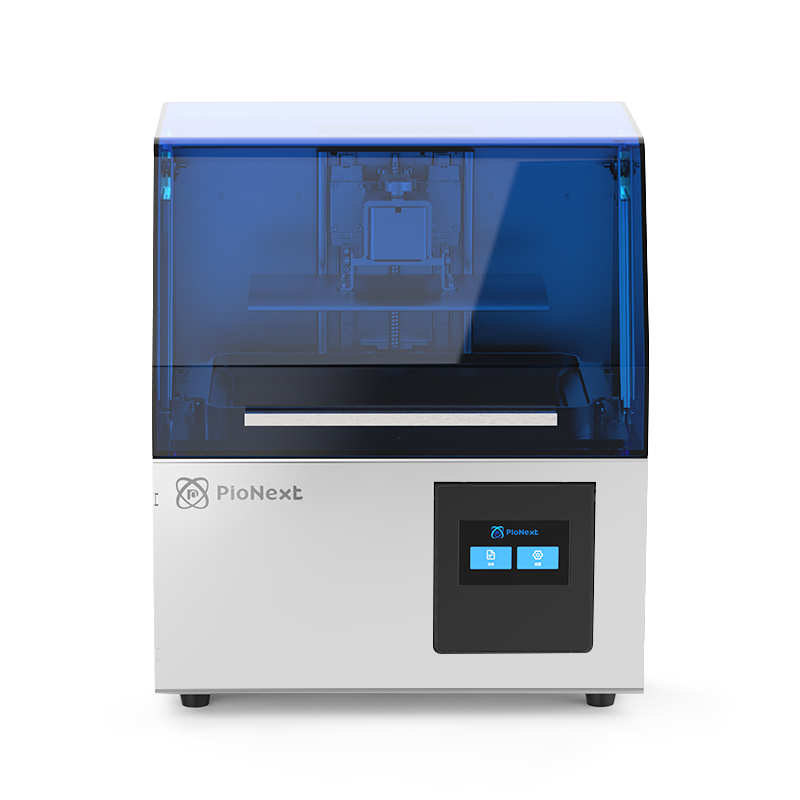

D150 DLP dental 3D printer, Newly developed high-power DLP projection light engine, high-definition projection, Stable z-axis structure design to print less layers and smoother surface models, light engine provides light uniformity up to 90%. Built-in automatic air purification system, Print speed 60-80mm/h, 5"full color touch screen, Print size 144×81×100mm. Adjustable light intensity: 6000-20000uw/cm2.

D150 could accomplish the printing tasks efficiently with high quality and reduces the laminated structure on the models as much as possible. Fully meet printing requirement of dental, jewelry, prototyping and others.

Free printed models available

To check and feel printing quality of Piocreat printers by yourself. Free models available.