2021/10/15

In most people's minds, 3D printing is only a change in the printing and appearance of models, but 3D printers can also print out physical objects through printing. So how does a 3D printer print real objects?

3D printing technology has created many business opportunities in the consumer field, and has also played an important role in the industrial manufacturing process. It can not only print models of mobile phone cases, tires, storage boxes, etc. with only appearance and simple structure, but also print them. Production-grade accessories and finished products with complex structure. For example, car wheels are 3D printed with metal, and furniture is a combination of steel and wood. When using 3D printing for train interiors, it is necessary to consider the difference between metal edging, decorative strips, buttons, switches and other materials.

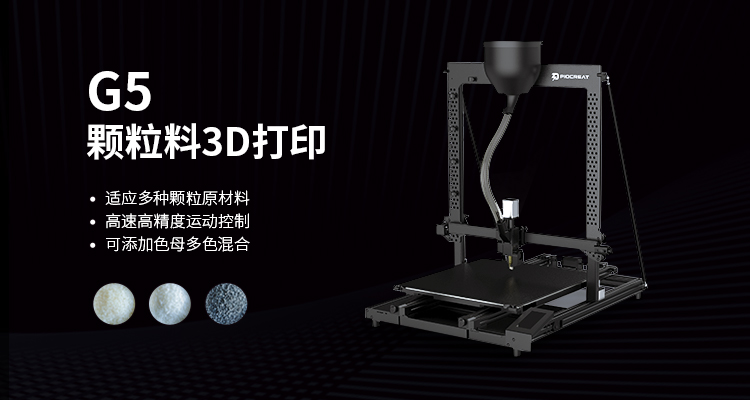

At present, the raw materials printed by mainstream 3D printers include solid metal powder, liquid metal powder, molten metal model inkjet, etc., and then generate the model according to the slices, and 3D print the parts. The parts are manually assembled to be the kind of work you want. . Take the Piocreat pellet 3D printer G5 as an example. The maximum printing size is 500*500*500mm, which can produce complex modeling parts, and use abundant printable materials as support to meet the manufacturing needs of various industrial parts and materials, especially It can print cermet consumables, which adds a strong impetus to industrial manufacturing.

In general, Piocreat pellet 3D Printer G5 has the following main features:

Photosensitive Light Curing Dental Resin, The material has fast forming speed, high forming precision and super high surface hardness, the most cost-effective dental resin for dental applications.

Features: Fine forming, Delicate Texture, Wide compatibility, Cost effective, High hardness, High precission.

Application: Invisible braces,Try-in model and others dental and medical applications.