Prosthetic dental molds have become increasingly popular in oral clinical application. Accurate grasp of implant sites has always been the goal of stomatologists. Using our

dental 3D printer to print restorative dental molds has good adaptability and accuracy. Combined with digital oral technology, it brings oral data with high precision, low cost, high efficiency and consistent with the standardized production chain to the dental industry.

Today, let's see how to combine

3D printer to make dental prosthesis. In fact, the process of 3D printing dental molds is not complicated.

1. As long as the patient's tooth data is scanned through a 3D scanner, an oral tooth model that can assist in accurate positioning is made. With the dental model data, we import the model into piocreat box software for slicing.

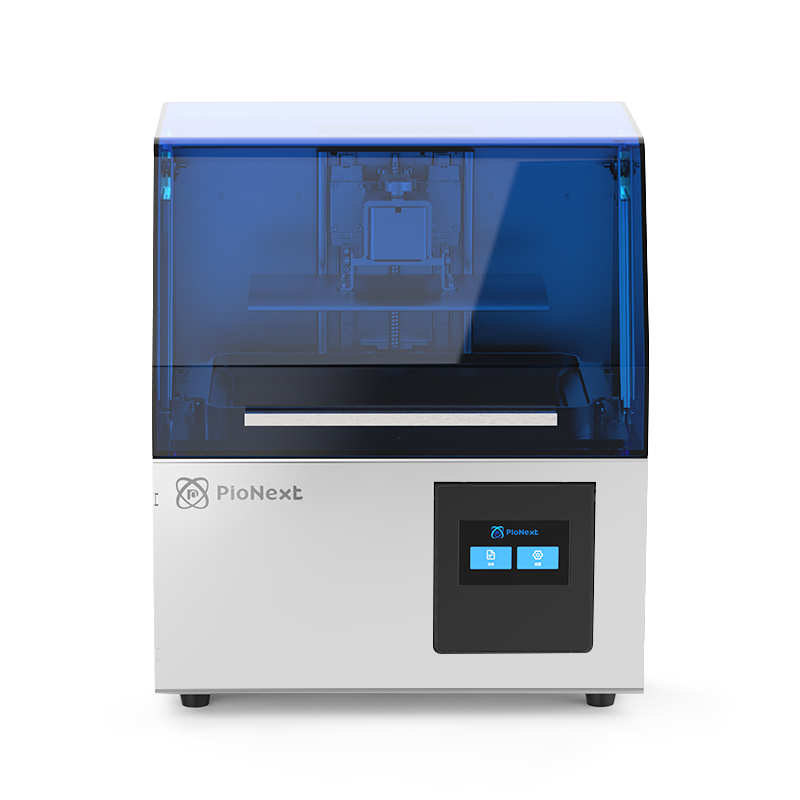

2. After the slice is cut, we can print 3D. Here, we print with the special 3D printer dj89 for dentistry and the special photosensitive resin for repairing dental molds,Parameter setting of dental model: bottom exposure time is set to 50s, delay light off is set to 1s, print exposure time is 5.5s, lifting distance is 8mm, motor speed is set to 3mm / s, and the number of bottom exposure layers is 2.

3. After setting, we press OK to start printing.

4. DJ89 adopts the new black-and-white monochrome imaging display technology. Compared with the ordinary LCD color screen, the black-and-white screen has high light transmittance, which is about 4 times higher than the color screen, the single-layer curing time is shortened to 1-4s, and the printing speed is greatly improved. At the same time, the screen resolution is up to 3840 * 2400! When printing various models, it can accurately capture the subtle and complex characteristics of the model, clearly present the points, sharp corners and surface details, and perfectly print the smooth, burr free and almost laminar model.

5. Now that the restoration dental model has been printed, we take down the dental model and wash it with alcohol. After cleaning, we use uv-01 for curing for 10 minutes.

After curing, let's take a look at the effect of the cured dental model. (finished product display)

With the application of 3D printing technology in the field of oral implant, it will not only bring changes to our concept, but also bring subversive development to oral clinic.