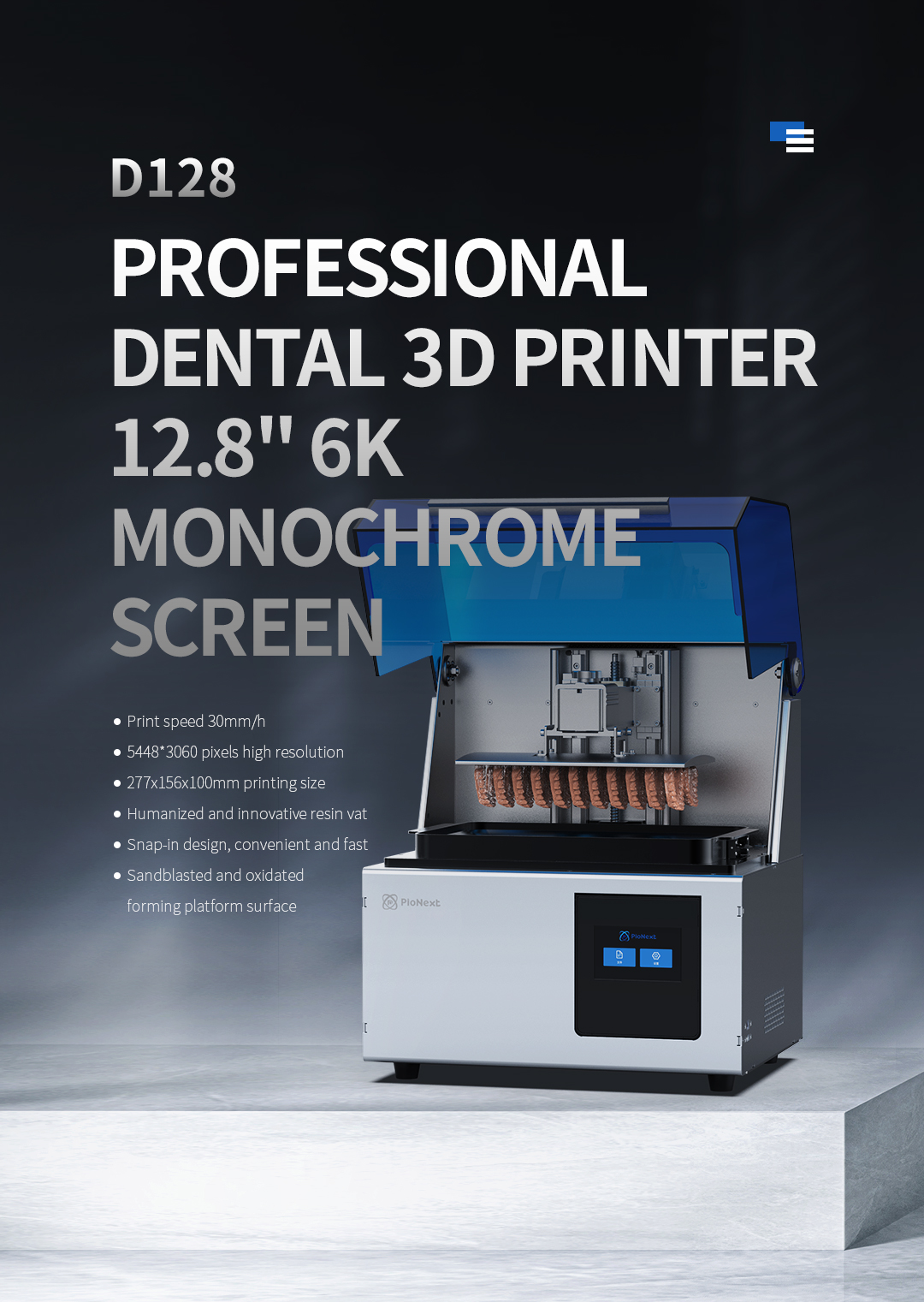

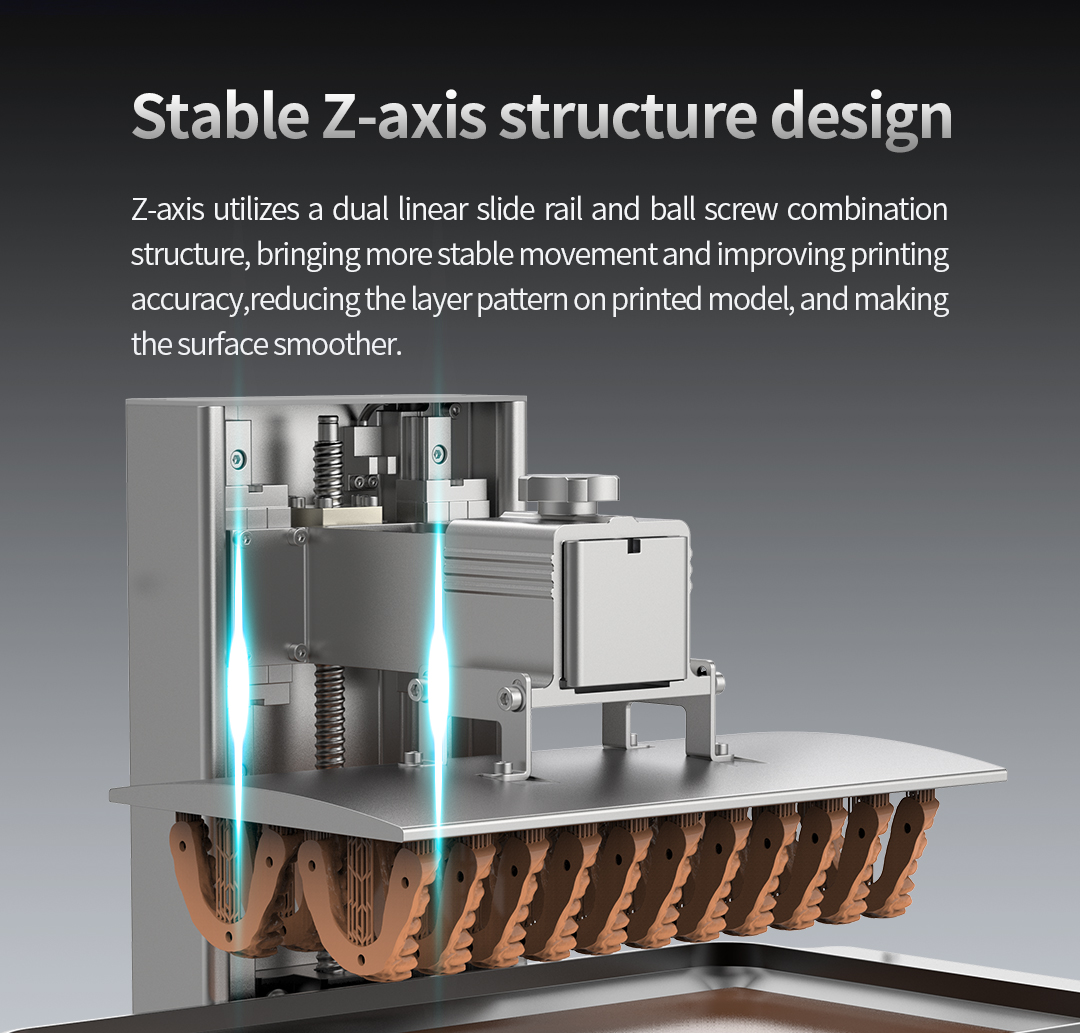

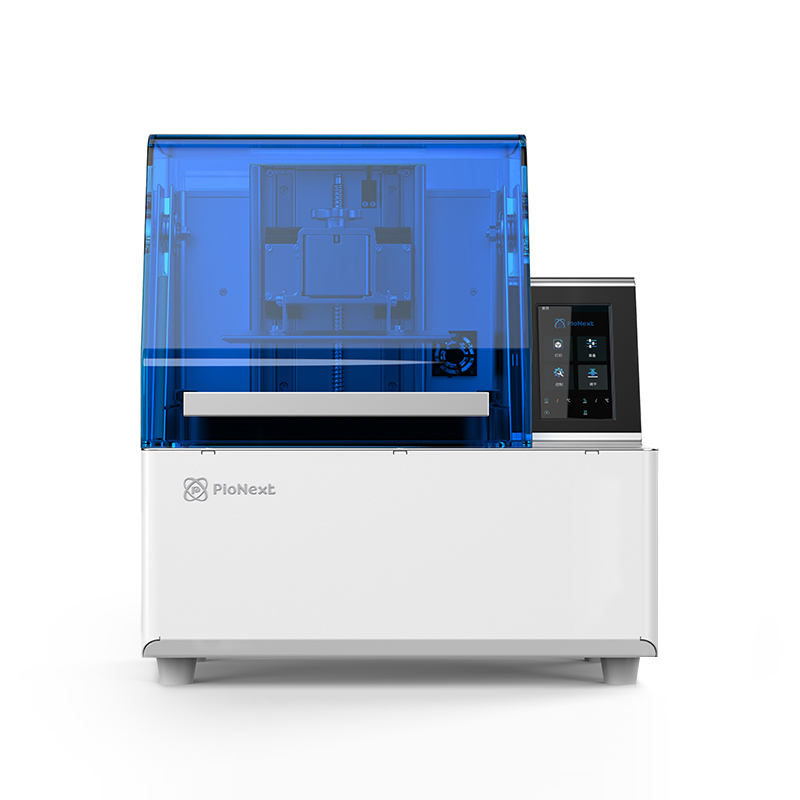

We found that the 3D printer printing platforms in the dental market are generally small, usually only 2-5 at one time. For denture processing plants with small batch production demand, this will reduce production efficiency and increase production costs. Now you see this d128 is also a light curing 3D printer used in the dental industry. It is a new large-size dental 3D printer launched by piocreat. What is the difference between it and other dental 3D printers on the market? First of all, from the printing platform, is 12.8-inch much larger than ordinary

dental 3D printer? Because of this, it can print more dental molds at one time. Secondly, d128 continues the integral light source technology of dental series models, and the details of the printed model are highly restored.

D128 has 6K, 5448 * 3060 high resolution, which can not only meet the needs of mass production, but also ensure high precision.

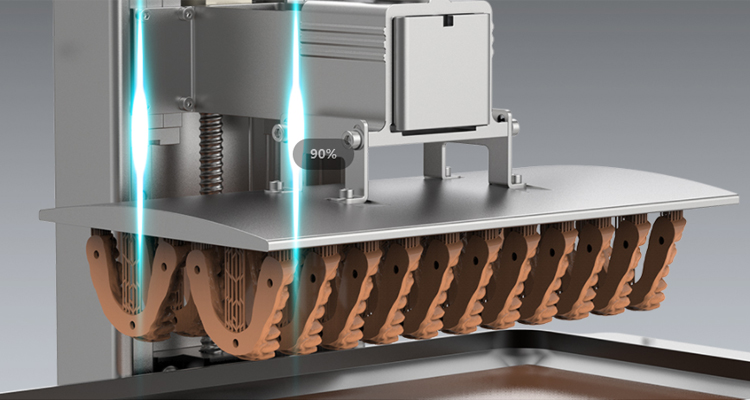

So how many dental molds can d128 print at one time? Let me show you today. First of all, let's slice the dental model. Import a dental model, copy 19 identical models, and then arrange them within the scope of d128 printing platform. After arranging, we will slice the software. After cutting the pieces, we can export the printing file.

We insert the cut model into the d128 3D printer. Next, we can see whether it can make so many dental molds at one time, how the effect is, and how long it will take. Here we choose the resin specially developed for dental molds, which has high printing accuracy and good reduction. We looked at the printing time of the whole dental molds, and this batch of dental molds can be printed in about three hours.

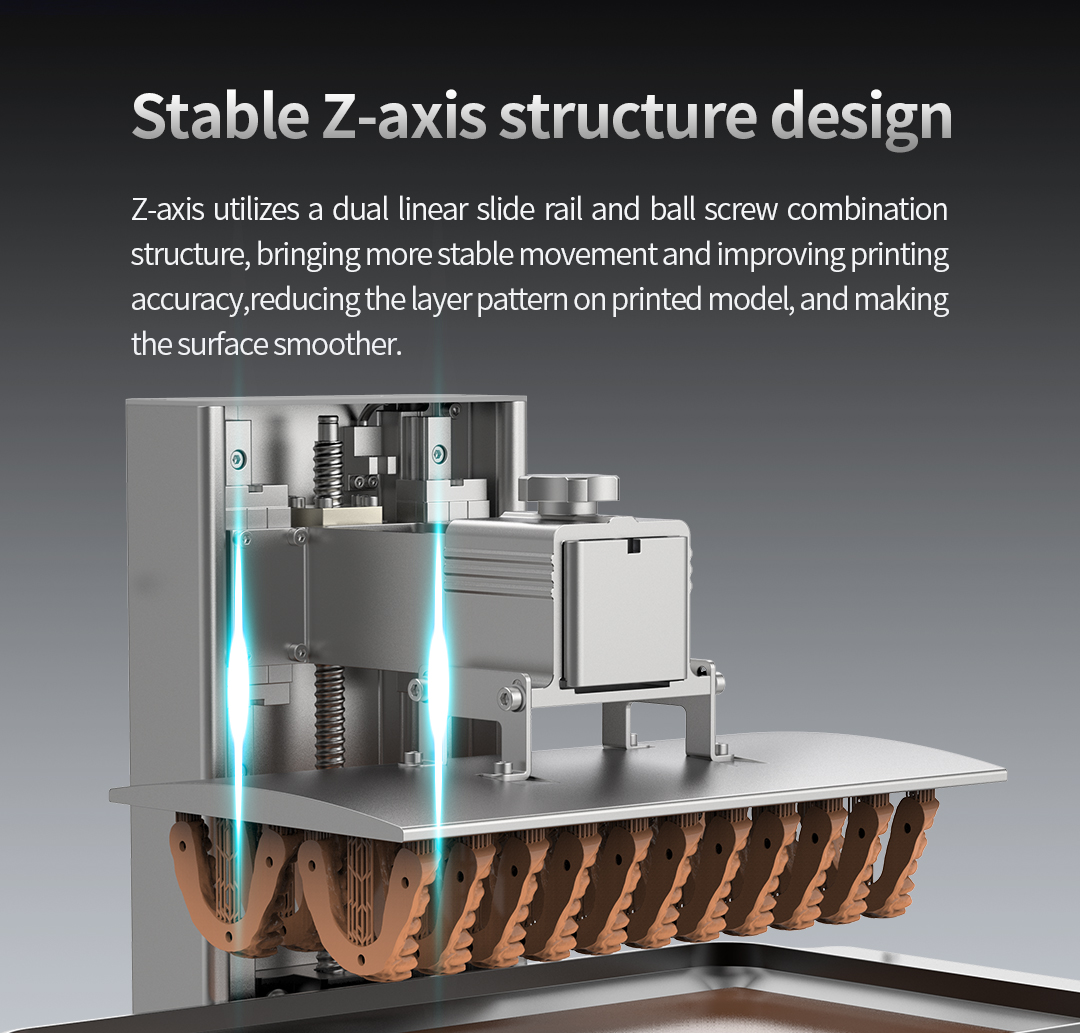

After three and a half hours of printing, the dental molds have been printed. We take them down and have a look. The overall effect is still very good. In terms of detail performance, it clearly presents the shape and edges of the dental molds. It can be said that it can perfectly print the smooth, burr free and almost laminar model. The accuracy requirement of dental model is much higher than that of ordinary manual model. A slight deviation will make the patient's experience very uncomfortable and even affect the final treatment effect. The printing speed of d128 is 30mm / h, with 6K and 5448 * 3060 high-resolution, higher precision integral light source and 277 × one hundred and fifty-six × With a printing size of 100mm, generally speaking, d128 is more cost-effective than the dental 3D printing equipment of tens of thousands of yuan or even hundreds of thousands on the market, and it is also more complex with the industry prospect of low-cost mass production in the dental industry.