With the aggravation of aging in China, the market scale of dental implants is growing at a compound annual growth rate of 46.3%. According to statistics, the number of dental implants in China in 2021 was about 5.5 million. Despite the impact of the epidemic, it still achieved an increase of about 45%. The huge market demand has also brought the development of domestic oral intelligent equipment.

Since december2020, the professional

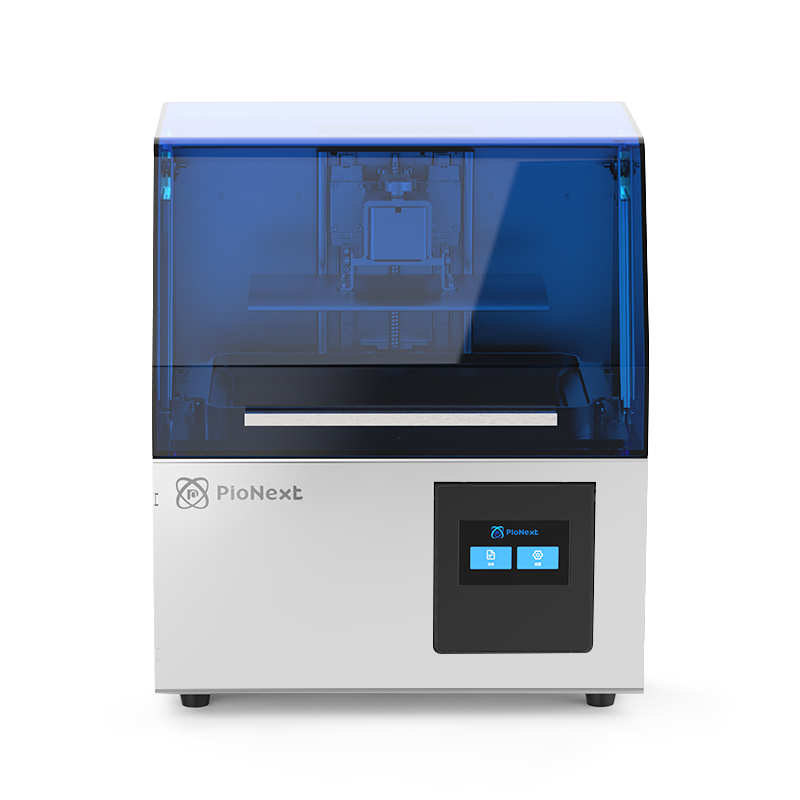

dental 3D printer DJ89 launched by piocreat for the dental industry has been favored by the market. More than 60 denture factories have used DJ89 to make dental molds to replace the traditional manual production. Why do denture manufacturers choose piocreat dental 3D printer?

The management of denture processing plant is becoming more and more difficult due to the lack of skilled workers

The traditional process of denture processing belongs to the manual industry, which is highly dependent on technicians. Nowadays, no one is willing to do this dirty and tired job, which leads to fewer and fewer technicians, more and more difficult to recruit, and higher labor costs. The traditional denture processing technology using gypsum materials for cutting will produce a lot of dust pollution, which is not very environmentally friendly. These two points lead to the increasing difficulty and cost of the denture factory.

Piocreat dental 3D printer helps denture factory realize digital unmanned production

Previously, although there were also 3D printing manufacturers involved in dentistry, they only made invisible orthodontic dental molds with low accuracy requirements, and most of them were small desktop machines, which could not meet the needs of denture processing. Piocreat is determined to overcome the technical barrier of denture 3D printing, and sends R & D personnel to the denture processing plant to communicate face-to-face with industry experts. After half a year, piocreat has developed a dental 3D printer dj89 specially used for orthodontics, restoration and implant guide plate production.

This model has a large printing format and high printing precision. It can make any geometric structure 360 degrees without dead angle, and can print high-precision plug-in dental molds required for denture processing. The dj89 dental 3D printer does not need to be on duty when it works, which makes the denture factory get rid of manual work. Piocreat provides a deep 3D printing solution, from oral scanning to prototyping, and the whole process is digitalized. Manual cutting is replaced by 3D printing, and 24-hour unmanned automatic production reduces labor and avoids pollution.

Technical advantages of dental 3D printer dj89

High precision is the remarkable feature of dj89. It can realize ultra-fine cutting and easy printing and plugging of dental molds. Dj89 also has eight core technologies, including 3840*2400 high-resolution, full-color touch screen, new integral light source, 3D nano release technology, ultra stable z-axis structure design, automatic air purification, wireless transmission and other eight core software technologies, with efficiency increased by 40%-100%. Compared with the traditional process, operators do not need to program frequently, which saves a lot of time and has higher overall efficiency.