Piocreat: Piocreat industrial 3D printing can meet diversified printing needs.

What is melt granulation?FGF 3D printing can be associated with the molten filament manufacturing (FFF) process because it uses chopped granular raw materials instead of filaments as a material source. FGF can convert raw materials directly to the printing bed, thus eliminating the "middleman" of FFF technology. FGF can meet the strength, stiffness and heat resistance required to create large 3D printing structure applications.

In fact, compared with FFF technology, FGF is especially suitable for large format 3D printing. Although FFF can be used to create large structures, it is usually limited by its limited extrusion rate due to the filament feeding system. FGF technology overcomes these limitations because it can extrude a large amount of materials through its inherent screw extrusion system. Therefore, various 3D printer OEMs are introducing FGF machines and compatible print heads to the market, but it is still far less widely used than FFF. FGF is hampered by "accessibility of low-cost granulators and shredders". In any case, FGF has proved its potential to become a more environmentally friendly and economical 3D printing method.

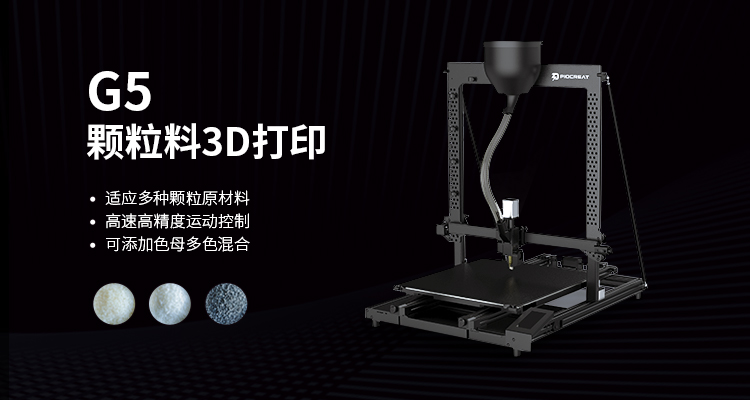

Piocreat G5 and G12

FGF 3D printers are equipped with a build volume of 500 mm x 500 mm x 500 mm and are part of the company's piocreat G series particle extrusion system.

Multi material adaptabilityThe piocreat G series is a truly reliable industrial grade machine that allows users to use mass-produced materials and expand their additive manufacturing work. Industrial 3D printer can be applied to a variety of granular materials, which is a highlight of piocreat granular 3D printer G5. It supports traditional commercial thermoplastic particles such as PVC, ABS, PC, PA, HDPE, TPU, and even special mixtures such as carbon fiber composites. In addition, users can also add color masterbatch in the printing process, which can not only improve the beauty of the model, but also meet the diversified printing needs of users.

Design of screw extrusion nozzle

Design of screw extrusion nozzleIt is worth mentioning that the G5 of chuangxiang Sandi particulate matter 3D printer adopts the design of screw extrusion nozzle to promote the full melting of consumables and ensure the stable and smooth discharge without plug. During operation, the extrusion force is large and the force is uniform, which greatly improves the printing efficiency, enhances the bonding force between printing layers, and makes the printing performance close to that of injection molded parts.

Powerful high-speed printing

Powerful high-speed printingAs a perfect product, the G5 of chuangxiang Sandi particulate matter 3D printer is extraordinary in printing speed. It breaks through the operation speed limitation of general 3D printers, up to 100mm / s. It can not only feel the rapid printing experience in an instant, but also affect the delicacy of the model.