With the continuous development and penetration of 3D printing technology, the craftsmanship of the jewelry industry has also undergone earth-shaking changes. Jewelry casting resin combined with light-curing 3D printers has become the industry's "sweet pastry". From design to prototype, to the melting, casting and final product in the foundry, digital manufacturing technology has become the key to the successful development of the jewelry industry.

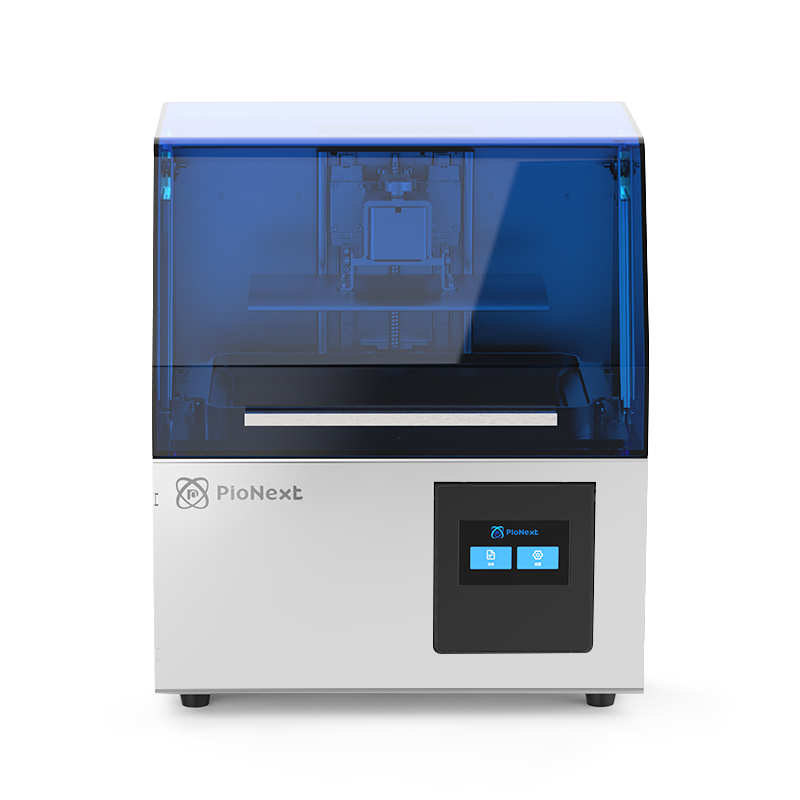

Before 3D printing, our prototype production was basically outsourced, and the difference between design and prototype could not be seen in real time. This not only increased the product design and production cycle, but also the cost of model production. The new castable wax resin 3D printing technology of Pionext light-curing 3D printer is very exciting. It has high printing accuracy, high material economy and easy casting. It is now deeply loved by the jewelry industry.

Diagram of traditional casting process:

Traditional jewelry casting process:

The designer designs the product;

Sculptors carve wax molds through design drawings;

Foundry workers make trees from carved wax molds;

Wrap the made wax pattern tree with gypsum and melt it in the combustion furnace;

Pour the metal liquid into the blank shell for casting (if only one piece is made, the process ends. If batch production is required, please continue);

Turn over the cast parts to make rubber mold;

Batch molding through rubber mold;

Group batch wax molds into trees;

Wrap the made wax pattern tree with gypsum and melt it in the combustion furnace;

Pouring the metal liquid into the green shell for casting;

Finally, the final product is obtained by grinding and polishing.

3D printing casting process diagram:

3D printing casting process:

The designer designs the three-dimensional model of the product;

Print the model through 3D printer (print according to the required quantity);

Foundry workers make trees from carved wax molds;

Wrap the made wax pattern tree with gypsum and melt it in the combustion furnace;

Pouring the metal liquid into the green shell for casting;

Finally, the final product is obtained by grinding and polishing.

3D printing casting process video:

3D printed jewelry wax molds have been successfully cast in 18k gold, sterling silver, and bronze. Cast using R & R casting and our standard burnout schedule. Other metals can also be cast by adjusting the final casting temperature and necessary changes.

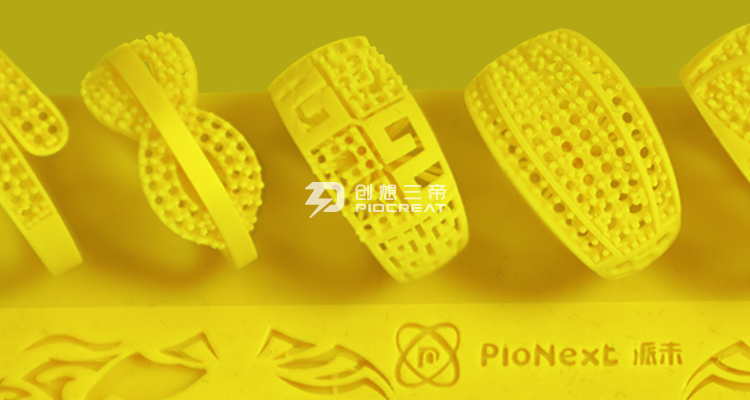

Here are the photos of our jewelry wax models printed in 3D: