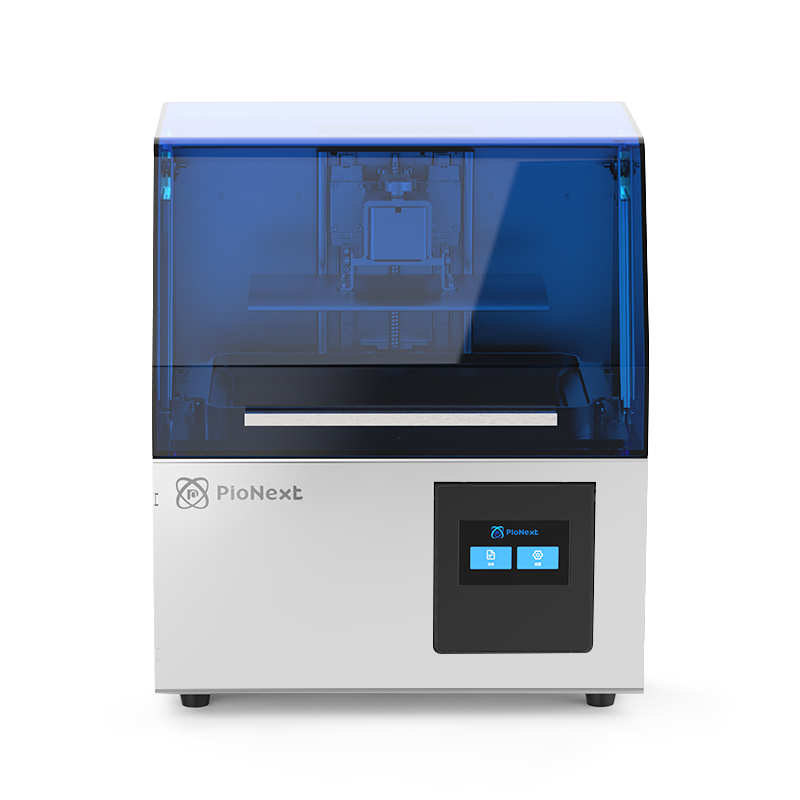

Pionext DJ-89 applies LCD printing technology to achieve industrial 3D printing quality

Pionext DJ-89 machine applies LCD printing technology, with a printing area of 8.9 inches, 4K high-definition black-and-white LCD screen, and the printing accuracy can reach 47 microns.

1. The machine adopts integral light source technology. Compared with ordinary parallel light source technology, this technology can achieve higher light uniformity. Parallel light source means that the lamp bead directly irradiates on the LCD screen. There are always a large number of repeated irradiation areas in the irradiation area between the light bead and the light bead, resulting in the light intensity in this area being higher than that in other areas. The integral light source is adopted. The light of each light bead will irradiate evenly on the LCD screen through the reflection principle, and the final output light source is obtained by superposition. If the output light intensity of a lamp bead is lower than that of other lamp beads, it will immediately show the final printing effect - printing failure, and its illuminated area will be directly affected. When using integral light source, the difference of one or more light beads will not have a direct impact on the effect. After that, the final output light source will be weakened. Users can solve the impact on the final product by increasing the exposure time of printing.

2. The machine adopts bilinear guide rail + roller screw rod, which can effectively strengthen the stability of z-axis printing. In the printing process, the printer moves up and down to achieve the printing effect, drops the light solid, the light solid ends to rise, then drops the light solid again, and repeats this movement repeatedly until the printing ends. A small model can usually be sliced into hundreds or even thousands of pieces through slicing software, that is, in order to print a small model, the printer needs to repeat this movement hundreds or even thousands of times. A stable z-axis structure design can bring certain stability to the printer and indirectly affect its printing effect. Usually, the accuracy we say refers to the pixel accuracy of the printer, and the final accuracy of the printer depends on some small details.

3. The print size of DJ-89 is only 100mm high. The design of this machine is mainly used in the field of Dentistry and jewelry. Generally, in this field, users do not need to print models with a height of more than 100mm. Therefore, Pionext did not consider this factor when designing this machine, and only designed a printing height of 100mm. Reducing the printing height can increase the stability of its z-axis, reduce unnecessary burden and increase the final printing accuracy of the machine. At present, most of the machines on the market are 200mm high. They are not specially designed for dental jewelry, but prefer general-purpose printers.