- 3D Printers

Pellet 3D Printer

Fused granulate fabrication

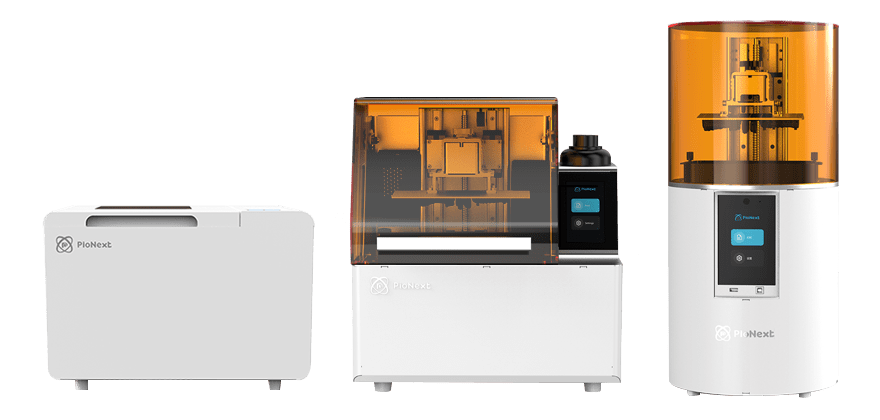

Consumer 3D Printer

14K LCD

- Material

- Application

- Support

- About

- 3D Printers

Pellet 3D Printer

Fused granulate fabrication

Consumer 3D Printer

14K LCD

- Material

- Application

- Support

- About