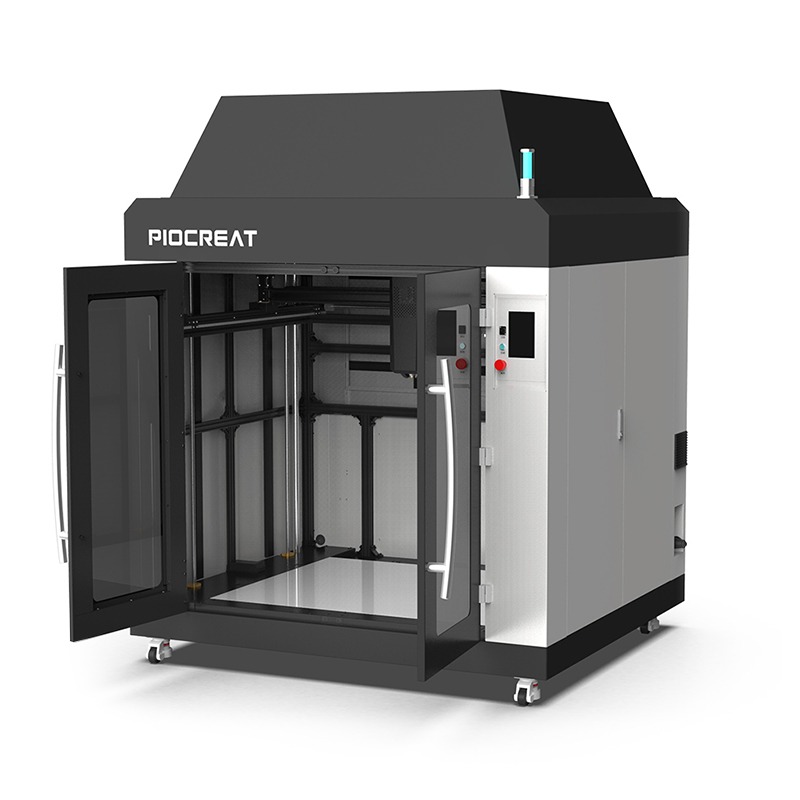

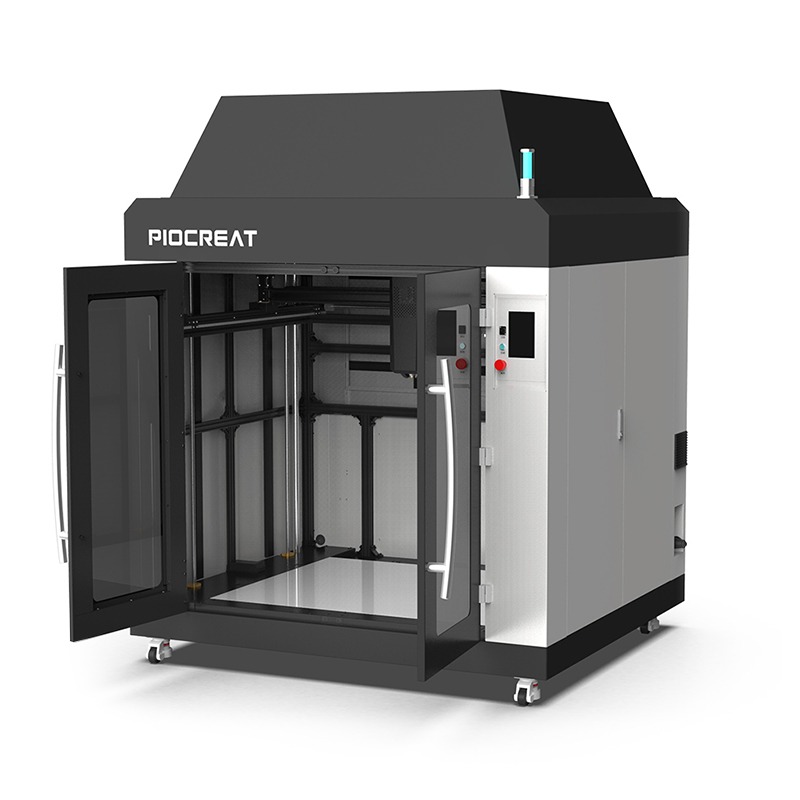

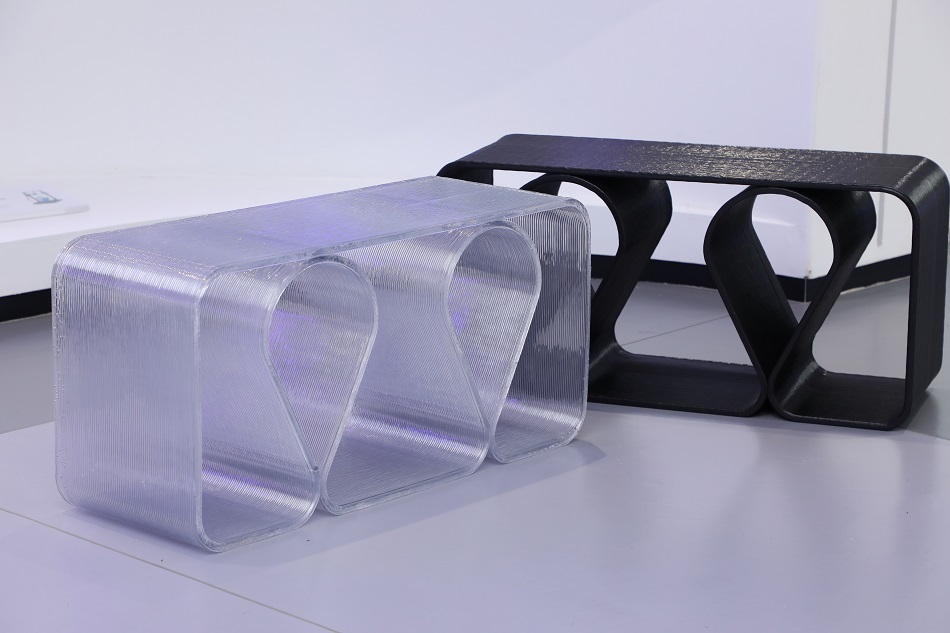

The G12 Fused granulate fabrication (FGF) pellet 3D printer is a large-format, high-speed thermoplastic extrusion printer designed for large-scale additive manufacturing. It is particularly suited for creating sizable patterns, molds, tooling, jigs, fixtures, batch production runs, and full-scale prototypes. The G12 is transforming a variety of sectors, including manufacturing, automotive, aerospace, art and furniture design.

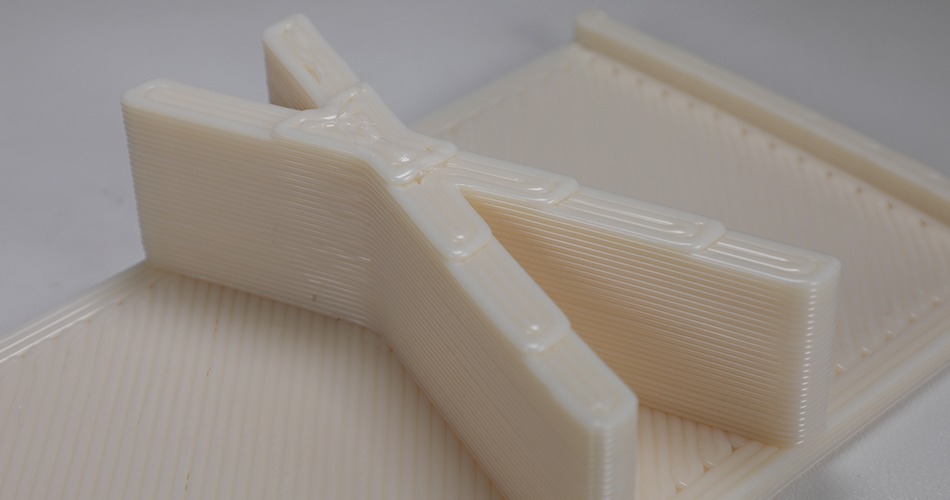

With a nozzle temperature reaching up to 450°C and a bed temperature of ≤130°C, the G12 Pellet 3D Printer’s nozzle is designed to handle high-temperature materials. This enables the printer to work with a wide array of thermoplastics and composite materials, including PLA, PETG, ABS, TPU, and composite materials, broadening the horizon for creating durable, complex parts with ease.

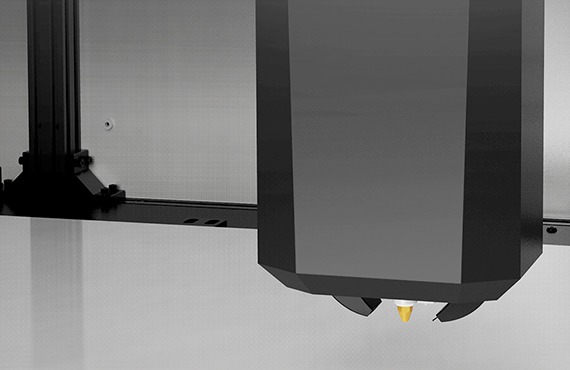

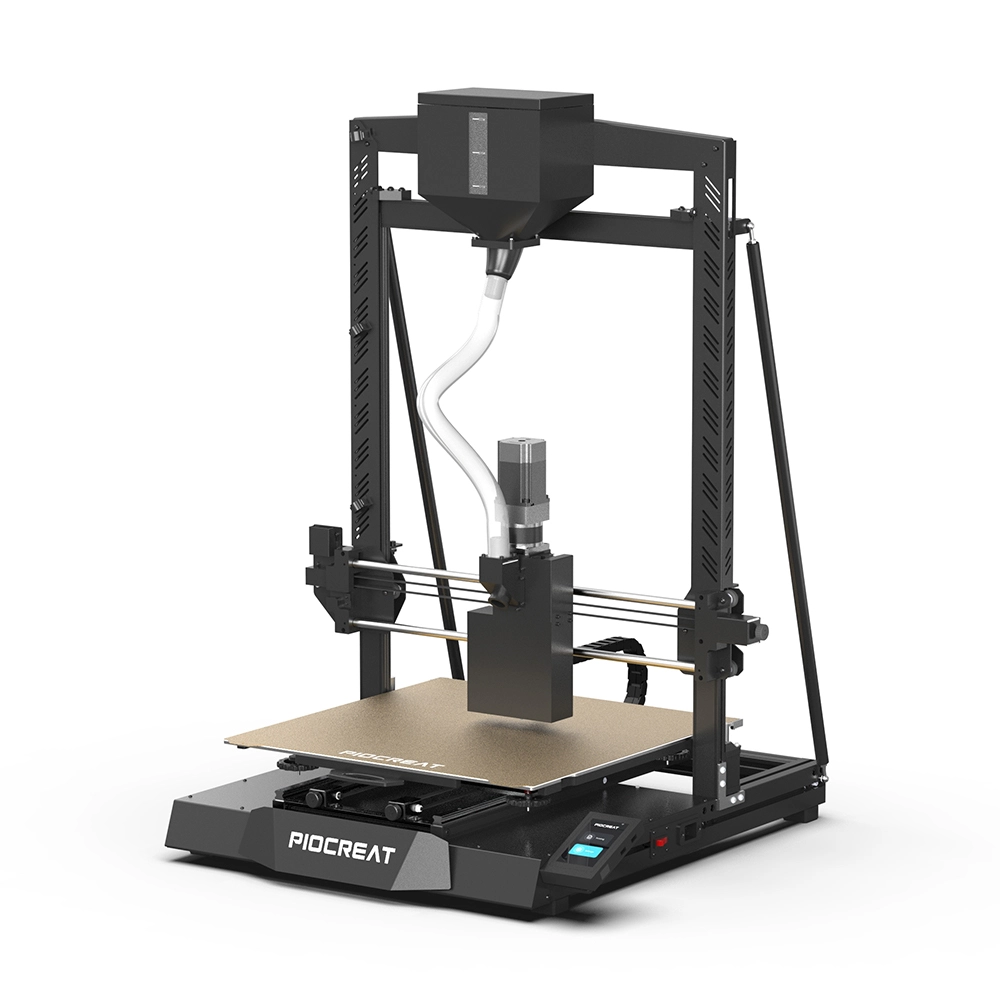

The G12 features a pioneering screw extrusion system, revolutionizing large-format 3D printing with its powerful, even extrusion force for uniform material flow and adhesion. It offers versatile slice thicknesses (0.2-1.5mm) and nozzle sizes (0.6-4mm), enabling both fine details and high flow rates (up to 3kg/hr), enhancing print quality and flexibility.

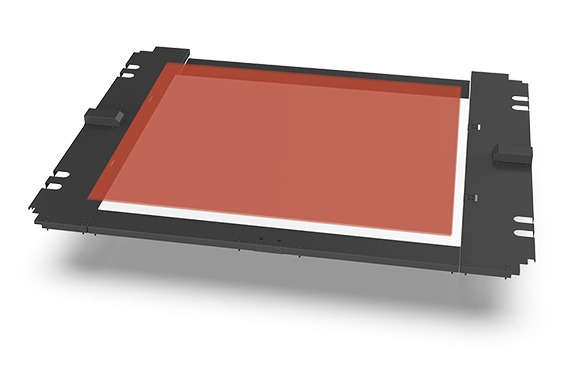

Accelerate your production timeline with the rapid-heating bed of the G12, capable of reaching temperatures up to 130°C. This feature greatly reduces the wait time for the printing set-up, enabling faster turnaround for projects, and ensuring optimal bed adhesion for large prints.

Precision is paramount when it comes to large-scale printing, and the G12 does not compromise. The integration of a customized, powerful servo motor translates to superior motion control and unparalleled printing accuracy. Whether you are printing intricate patterns, molds, tooling, or full-scale prototypes, the G12 delivers quality prints with a level of detail that sets it apart from the competition.

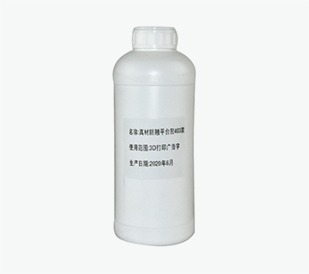

Pellet extrusion 3D printing offers significant savings, cutting costs up to 10X compared to traditional filament-based methods.

Enjoy speeds up to 10X faster than conventional filament extrusion 3D printing, drastically reducing project lead times.

Use original materials for optimal material properties, ensuring enhanced performance of printed components through superior quality.

Our 3D printing innovation uses pellets and shredded recycled plastic for sustainable, eco-friendly additive manufacturing alternatives.

| G12 Pellet 3D Printer Parameters | |

|---|---|

| Technical | FGF Fused Granulate Fabrication |

| Built Volume | 1200 x 1000 x 1000mm |

| Machine Size | 2135x1775×2305mm |

| Package size | 1980×1810×2150mm |

| Feeding structure | Screw Rod Extrusion |

| Nozzle | Single Nozzle |

| Nozzle Diameter | 0.6-4mm |

| Printing Layer | 0.2-1.5mm |

| Particles Diameter | 2-5mm |

| Hotbed Tempature | ≤130°C |

| Nozzle Tempature | ≤450°C |

| Printing speed | 80~100mm/s |

| Flow Rates | 3kg/h |

| Power Voltage | AC220V |

| Rated Power | 7000W |

| Slicer software | Piocreat_Slicer |

| Files Format | STL/OBJ/AMF |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

Cut your material costs by more than 60% by printing with Plastic pellets and recycled plastics instead of filament.

Various types of nozzles 0.4,0.8, 1.0, 1.5, 2.0, 3.0, 4.0,etc.

Independent research and development, multi-point detection, intelligent compensation.

Maximum temperature 450°C, Consumables melt thoroughly and extrude smoothly.

3D printer insulation cover, Thermal insulation, constant temperature printing.

Heating up quickly,reducing waiting time for printing. The platform is easy to put and take,can be bent,easy to take the mold.

Copyright © 2024 PioCreat 3D Technology Co., Ltd. All Rights Reserved.