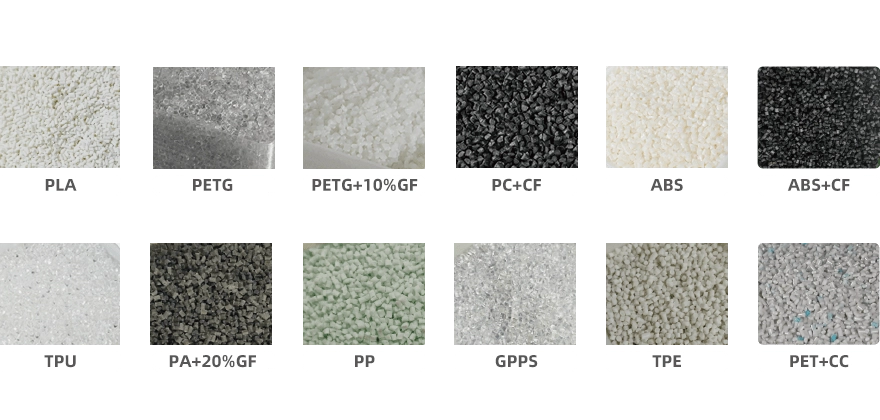

Cut your material costs by more than 60% by printing with Plastic pellets and recycled plastics instead of filament. For a wide range of applications, 3D printing with pellets and shredded recycled plastic is a financial and environmental win-win.

The G5Ultra Pellet 3D Printer is a desktop, high-speed industrial production system utilizing low-cost thermoplastic pellet feedstocks.

The G12 Pellet 3D Printer is a large-format pellet extrusion printer capable of printing medium-to-large format parts.

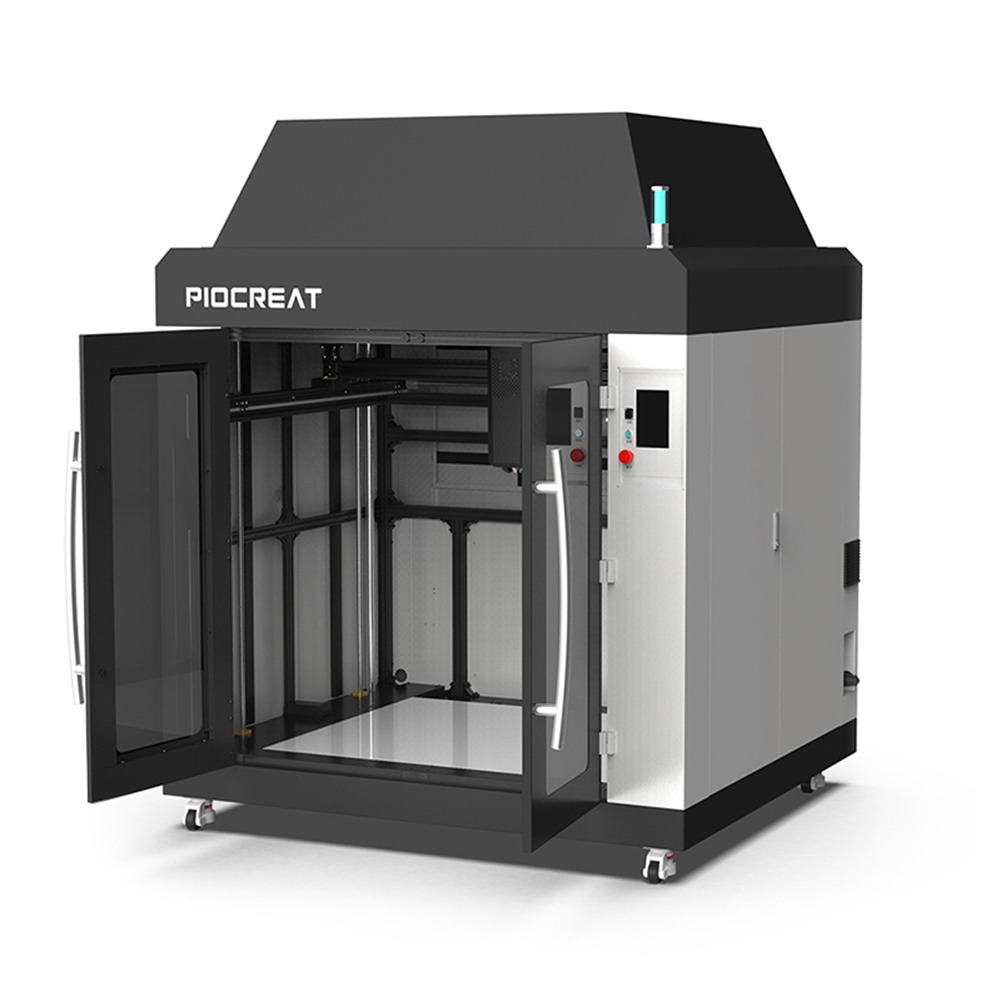

The G40 Pellet 3D Printer, PioCreat’s largest industrial printer, is a versatile and reliable industrial additive and CNC five-axis manufacturing integrated Machine.

Our 3D printing materials range, including various thermoplastics and composites, caters to specific application needs including flexibility, durability, strength, transparency, and temperature resistance.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.