In today’s design landscape, sustainability, personalization, and cutting-edge technology are no longer separate priorities—they’re interwoven. At the intersection of these trends lies one of the most exciting developments in lighting and décor: 3D printed lamps. Leveraging additive manufacturing, designers and manufacturers are reshaping how lighting is conceived, produced, and experienced—reducing waste, embracing eco-friendly materials, and delivering stunning, nature-inspired aesthetics.

Additive Manufacturing: A New Light on Sustainable Design

With 3D printing, especially pellet 3D printing, we are embracing a shift toward sustainable production methods that minimize environmental impact. Traditional lamp manufacturing often involves multiple material processes, wasteful offcuts, and shipping inefficiencies. In contrast, 3D printing enables on-demand, zero-waste fabrication, significantly reducing carbon emissions and production waste.

By printing directly from low-cost thermoplastic pellets—including biodegradable and recycled plastics—we eliminate the need for energy-intensive intermediate steps. This streamlined production not only benefits the planet but also allows unparalleled flexibility in design.

Nature-Inspired Designs That Illuminate More Than Just a Room

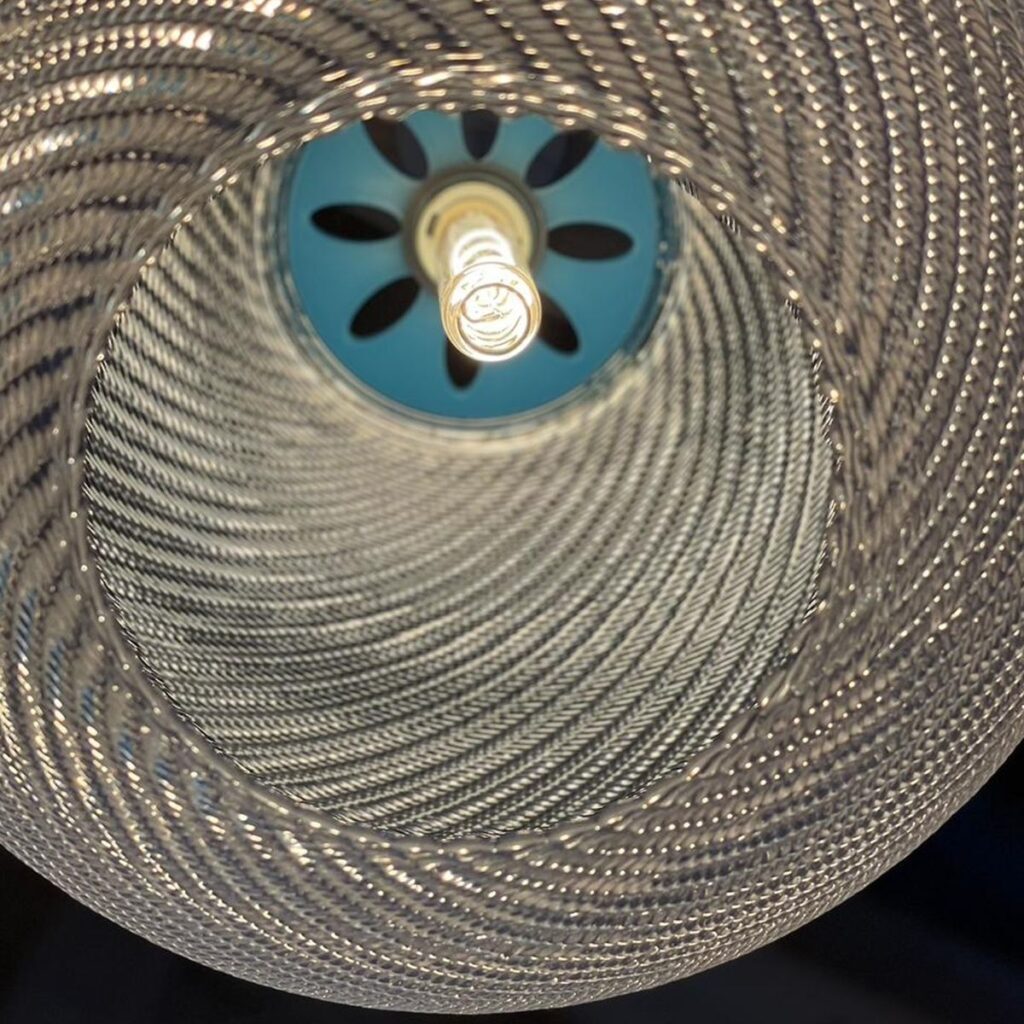

3D printed lamps are more than functional light sources—they are sculptural centerpieces. Drawing inspiration from the intricate forms found in nature—leaf veins, coral structures, honeycombs, and wave patterns—these lampshades reflect an organic elegance that’s both timeless and futuristic.

The layered manufacturing process of 3D printing beautifully captures these complex geometries, resulting in lampshades that diffuse light in captivating ways, casting delicate shadows and soft glows that add depth and atmosphere to any space.

Sustainable Materials That Support A Greener Future

Beyond aesthetics, the choice of materials is central to the appeal of 3D printed lighting. Many 3D printed lamps are created using biodegradable composites—often PLA blends reinforced with natural fibers like bamboo, hemp, or flax. Others use PETG made from recycled plastic bottles, combining durability with eco-conscious sourcing.

These materials are:

Lightweight, making installation easier and safer.

Heat-resistant, suitable for various lighting applications.

Environmentally responsible, aligning with modern sustainability goals.

Captivating Aesthetics and Flexible Integration

Whether minimalist or expressive, 3D printed lamps offer unmatched freedom in form. The layering process allows for precise texture, translucency, and geometry, enabling unique interactions between light and shade.

This makes them ideal for:

Modern interior styles seeking a statement piece.

Workspaces needing ambient, diffused lighting.

Hospitality settings, where atmosphere is everything.

Their modular production also allows for scalable customization, from one-of-a-kind gallery pieces to small-batch production for boutique brands.

Bringing Light to Life with Pellet 3D Printing

Imagine a design studio crafting custom table lamps using our G5Ultra Pellet 3D Printer and PETG recycled plastic. The result is not only visually striking—thanks to the textured, layered surface that catches light and shadow—but also tactically compelling.

When illuminated, the lamp casts a warm, ethereal glow, with intricate geometric or organic patterns that become an ambient artwork. The design becomes more than just a light fixture—it’s an emotional experience, a tactile conversation between structure and light.

Each lamp can be tailored for specific moods, environments, or brand identities—something traditional manufacturing can’t deliver at the same cost or speed.

3D Printers Ideal for Lamp Design and Production

G5Ultra Pellet 3D Printer

A powerful desktop solution for designers and small manufacturers looking to create custom lighting components with industrial-grade precision.

Specifications:

Build Volume: 500×500×400mm

Nozzle Temperature: Up to 400℃

Hot Bed: Rapid heating up to 120℃

Screw Extruder: Compatible with a wide range of materials, including recycled and composite pellets

Why it’s ideal: Compact but powerful, the G5Ultra is perfect for creating table lamps, wall fixtures, and decorative lighting elements with fine detail and fast turnaround.

G12 Pellet 3D Printer

For those producing medium-to-large-scale lighting or furniture pieces, the G12 delivers unmatched capability and reliability.

Specifications:

Build Volume: 1200×1000×1000mm

Nozzle Temperature: Up to 450°C

Heated Bed: Up to 120°C

High Flow Screw Extrusion: Ideal for efficient printing of large or complex designs

Best suited for: Furniture-integrated lighting, architectural lighting features, or batch production of custom lamp collections.

Why 3D Printed Lamps Matter for Designers and Manufacturers

Speed to Market: Rapid prototyping means quicker client approvals and faster iterations.

Cost Control: No need for expensive molds or tooling—just digital files and pellets.

Design Freedom: No limits to form or texture, enabling creative expression and functional innovation.

Sustainability: Every lamp printed is a step away from traditional waste-heavy methods, aligning your brand with growing eco-conscious consumer values.