3D Printing Techniques in Jewelry

3D printing plays a crucial role in various stages of jewelry production, offering designers and manufacturers a fast and accurate way to create intricate designs. Here are some of the key ways 3D printing is applied in the jewelry industry:

Lost Wax Casting

One of the most traditional methods in jewelry making, lost wax casting, has been greatly enhanced by 3D printing. Traditionally, a wax model of the jewelry piece would be hand-carved or sculpted. With 3D printing, jewelers can now design the model digitally and print it in castable wax resin. Once the model is printed, it is used in the lost wax casting process, where the wax is melted away, leaving a mold that can be filled with precious metal.

This method allows for incredible precision, reducing the potential for human error and enabling the creation of highly detailed and complex designs that would be challenging or impossible to craft by hand.

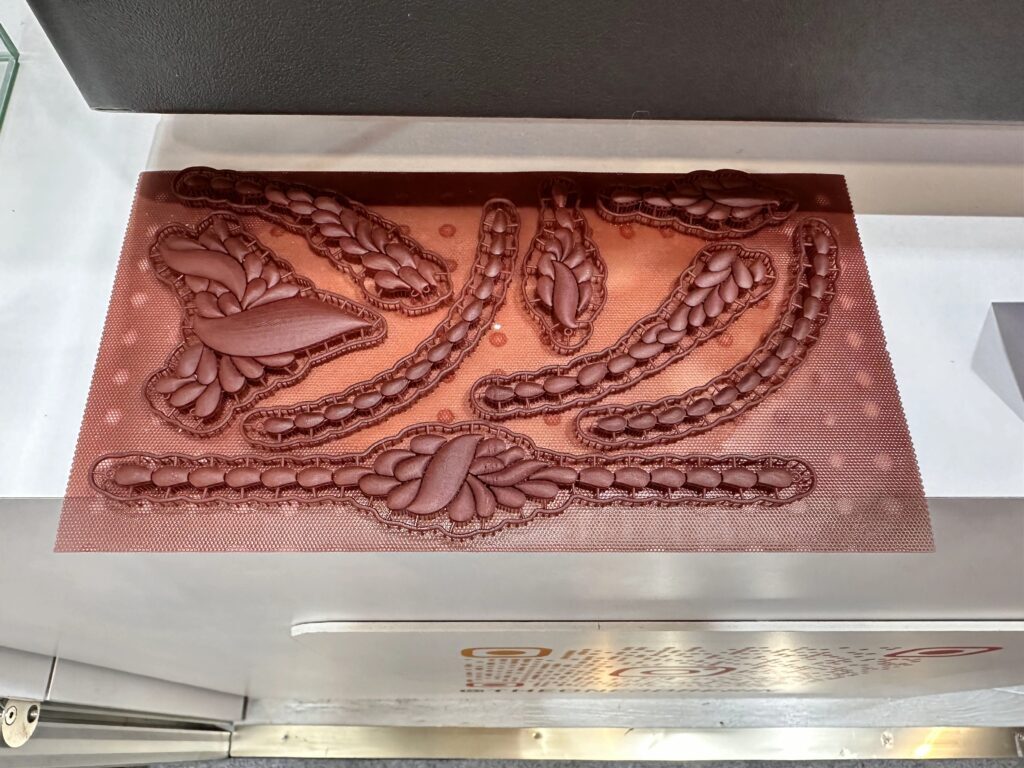

Mold Making

3D printing also plays a significant role in mold making for jewelry. Instead of relying on traditional hand-carved molds, 3D printers can create high-temperature-resistant molds with intricate details. These molds can be used repeatedly, ensuring consistency in each piece produced.

Rubber mold resins are often used for mold making, as they offer high-temperature resistance (up to 170°C) and durability, making them ideal for multiple casting runs. This method reduces the time and cost associated with traditional mold-making processes.

Prototyping

Rapid prototyping is one of the most significant benefits of 3D printing in the jewelry industry. Designers can now quickly create prototypes of their jewelry pieces, allowing them to test designs, make adjustments, and finalize products before moving on to mass production. This capability not only speeds up the design process but also enables jewelers to experiment with more intricate and complex designs.

Prototyping with 3D printing eliminates the need for costly tooling and hand-carving, giving designers the flexibility to innovate without the fear of wasting materials or time.

Advantages of 3D Printing Jewelry Models

The adoption of 3D printing in the jewelry industry offers several advantages that help jewelers streamline their processes, reduce costs, and increase creative possibilities:

Speed

3D printing significantly reduces the time it takes to go from concept to finished product. In the past, hand-carving a wax model could take days or even weeks. With 3D printing, detailed models can be produced in just a few hours. This speed allows for faster design iterations and quicker delivery times, making it easier to meet customer demands and timelines.

Customization

One of the biggest trends in the jewelry industry is customization. With 3D printing, creating custom, one-of-a-kind pieces has never been easier. Designers can quickly alter digital models to meet the specific preferences of individual clients, allowing them to offer truly personalized jewelry without needing to start from scratch each time.

Complexity

3D printing allows for the creation of complex and intricate designs that would be impossible or extremely difficult to achieve using traditional methods. Geometrically intricate patterns, fine filigree work, and delicate shapes can all be easily printed with precision, enabling designers to push the boundaries of what is possible in jewelry design.

Cost-Efficiency

Because 3D printing reduces the need for labor-intensive hand-carving and allows for rapid prototyping, it is far more cost-efficient than traditional methods. Additionally, the ability to print molds and models on demand reduces material waste and the need for expensive tools. This makes 3D printing a financially viable option for small-scale jewelers and large manufacturers alike.

Wax & Casting Materials

The materials used in 3D printing for jewelry must be of the highest quality to ensure the production of flawless, detailed pieces. Several types of resins are available specifically for jewelry casting, offering various levels of wax content to achieve different casting results:

Castable Wax Resin

Castable Wax Resin is one of the most popular materials for creating detailed jewelry models for lost wax casting. This resin is formulated with 15% wax, allowing for clean burnout in the casting process and ensuring a flawless finish.

Castable White Wax Resin

Castable White Wax Resin contains 20% wax and is designed to produce even smoother and more detailed jewelry models. Its clean-burning properties make it ideal for highly intricate designs where precision is paramount.

Castable High Wax Resin

For even higher precision and smoother finishes, Castable High Wax Resin offers 30% wax content, ensuring clean burnouts during the casting process. This resin is particularly suited for creating highly detailed pieces with delicate features.

Rubber Mold Resin

Rubber Mold Resin is designed for mold-making applications and can withstand high temperatures up to 170°C. This makes it ideal for creating durable molds that can be reused multiple times without losing detail or accuracy.

Best Affordable 3D Printers for Jewelry

When choosing a 3D printer for jewelry design and manufacturing, it’s important to consider factors such as print resolution, speed, and cost. Here are two highly recommended and affordable 3D printers ideal for jewelers:

DJ89 PLUS 8K 10.3" LCD 3D Printer

The DJ89 PLUS is a top cost-effective 3D printer for the jewelry industry, offering unparalleled print clarity and detail thanks to its 8K 10.3″ LCD screen. This resin 3D printer is perfect for producing intricate jewelry models with fine details, making it ideal for small-scale jewelers and large production houses alike.

- Key Features:

- 29μm pixel size for high precision

- Heating chamber for consistent resin performance

- Automatic feeding system for ease of use

- Stable Z-axis for reliable, repeatable results

C01 14K LCD 3D Printer

For jewelers looking to produce high-resolution, detailed models at faster speeds, the C01 14K LCD 3D Printer is an excellent choice. It features a 10.1-inch HD monochrome LCD with 14K resolution, delivering unmatched accuracy and speed for producing jewelry prototypes and castable models.

- Key Features:

- 14K resolution for incredible detail

- High-speed printing for faster production cycles

- Large build volume for producing multiple models at once

- HD monochrome LCD for better light efficiency and longer printer lifespan

Final Thoughts

3D printing has completely revolutionized the jewelry industry, making it easier, faster, and more cost-effective to create detailed, customized pieces. From lost wax casting to rapid prototyping, 3D printing offers endless possibilities for jewelers to push the boundaries of design and improve their production processes.

By leveraging high-quality resins like castable wax and rubber mold resin, jewelers can produce flawless, intricate pieces with minimal waste. Affordable 3D printers like the DJ89 PLUS and C01 14K LCD 3D Printer make it possible for jewelers of all sizes to take advantage of these technologies, unlocking new levels of creativity and efficiency in their work.