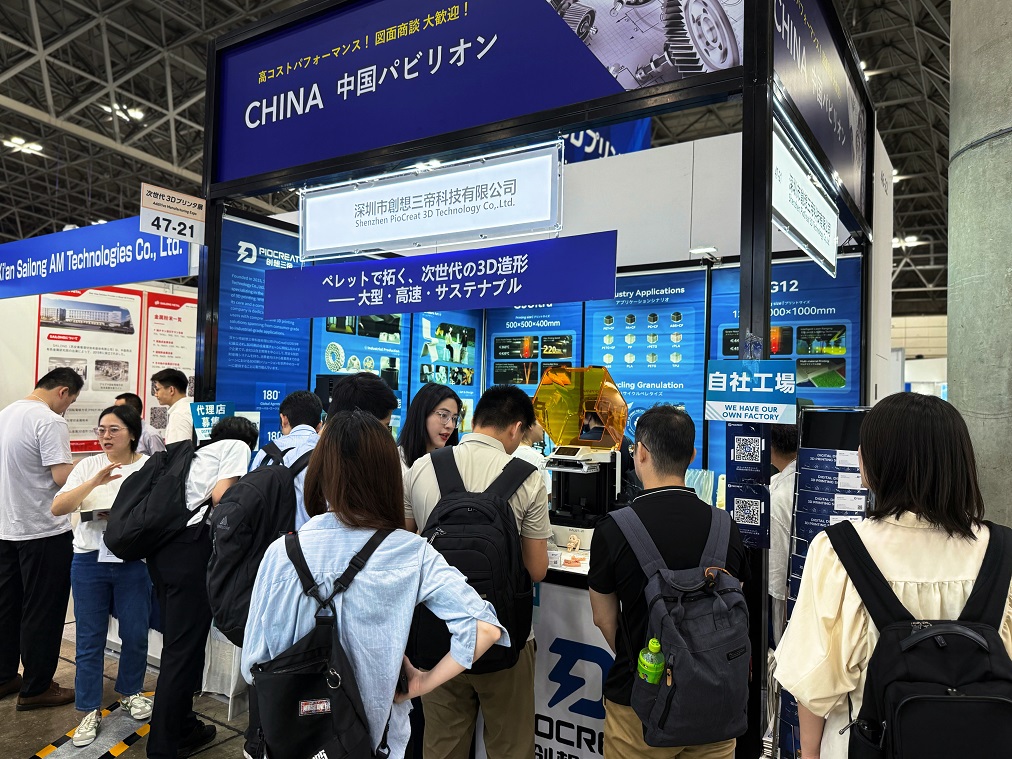

PioCreat, a global innovator in 3D printing technologies, participated in the Additive Manufacturing Expo Tokyo 2025, held as part of Manufacturing World Japan, one of Asia’s leading exhibitions for cutting-edge manufacturing technologies. The event brought together top-tier professionals from industries such as prototyping, product design, automotive, aerospace, and healthcare, all seeking the latest advancements in additive manufacturing.

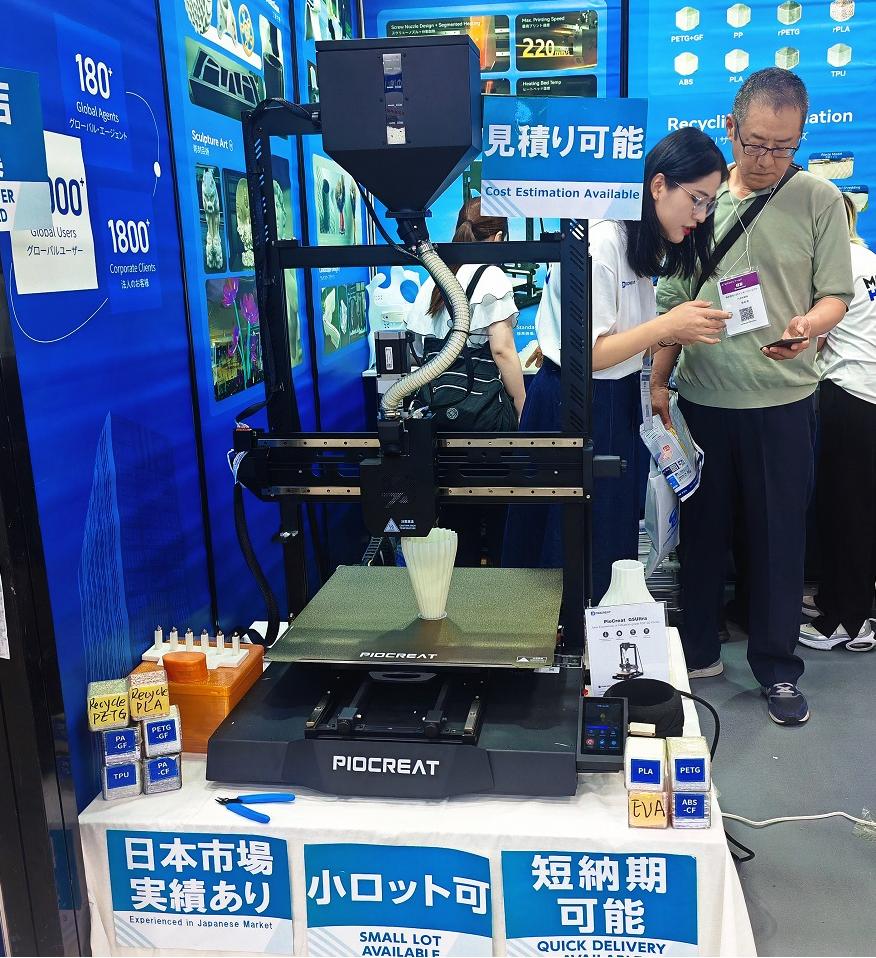

At the heart of PioCreat’s showcase were two standout products: the G5Ultra Pellet 3D Printer and the newly launched HALOT-X1 16K Resin 3D Printer.

The G5Ultra, known for its large build volume (500×500×400mm) and high-speed pellet extrusion system, impressed attendees with its ability to reduce material costs while delivering industrial-grade precision. With a nozzle temperature of up to 420°C and compatibility with a wide range of thermoplastic pellets, the G5Ultra is optimized for prototyping, design research, and small-batch production—ideal for companies looking to innovate sustainably and efficiently.

The HALOT-X1, making its debut in the Japanese market, drew significant attention with its 16K ultra-high resolution, 92-zone intelligent exposure system, and no-leveling-required design. Engineered for consumer accessibility without compromising professional results, the HALOT-X1 represents the next generation of desktop resin 3D printing.

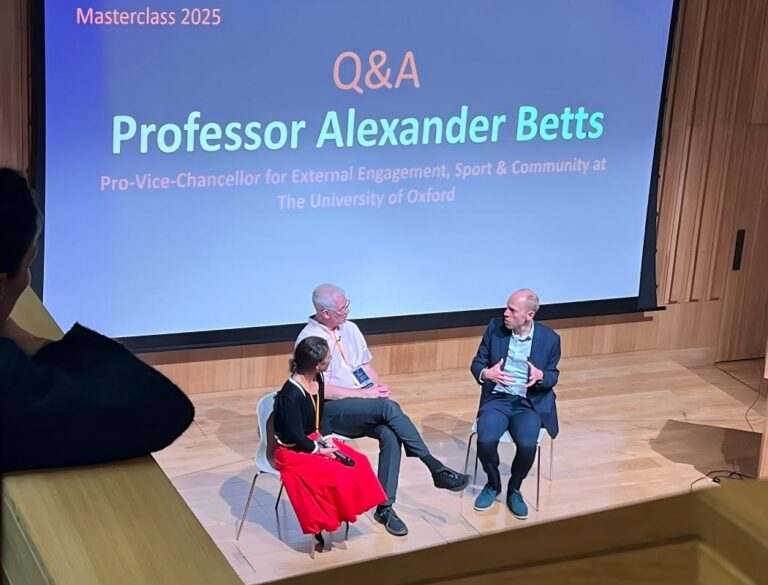

Throughout the event, PioCreat engaged with engineers, designers, and decision-makers, demonstrating how its solutions can drive digital transformation across industries. The company’s commitment to open material compatibility, user-friendly design, and cost-effective workflows resonated with professionals looking to upgrade their additive manufacturing capabilities.

As demand for smart, scalable 3D printing continues to grow, PioCreat remains dedicated to advancing industrial and consumer applications with its innovative technologies.