Transform the way you create signage with the groundbreaking K8 Channel Letter 3D Printing Machine – your advanced solution to the cumbersome production woes of traditional advertising letters. Designed with precision engineering and cutting-edge technology, the K8 is set to redefine the industry standards for manufacturing luminous letters. Say goodbye to the complex, costly, and environmentally unfriendly processes of yesteryear, and embrace the future of signage production.

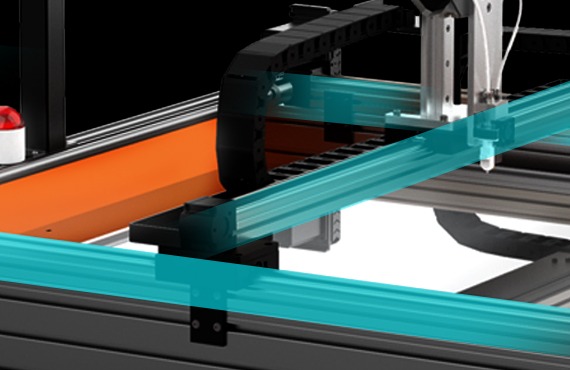

The K8 boasts a high-end module that guarantees impeccable accuracy in every minute movement. Crafted for perfection, each curve and line of your 3D printed channel letters will reflect the highest level of detail, ensuring that your signage stands out with professional finesse.

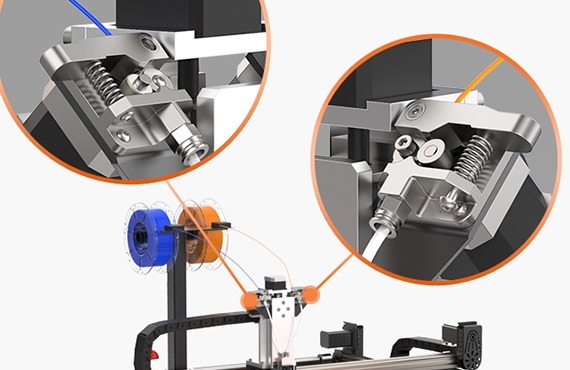

Our innovative double-in and single-out feature revolutionizes the filament switching process. With the ability to switch filaments in just one second, and without the need for manual intervention, you can enjoy a seamless printing experience that keeps up with the fast-paced demands of the signage industry.

With its powerful dual extrusion system that features dual gears, the K8 ensures strong and consistent feeding performance. This robust mechanism lays down material with exceptional reliability, providing you with high-quality prints that exhibit both strength and durability.

Got a power cut mid-operation or the filament depleted? Fear not! The K8 possess a resume printing function, providing your project a free pass from interruptions. Get back exactly where you left off, skipping the provoking process of redundantly starting all over again.

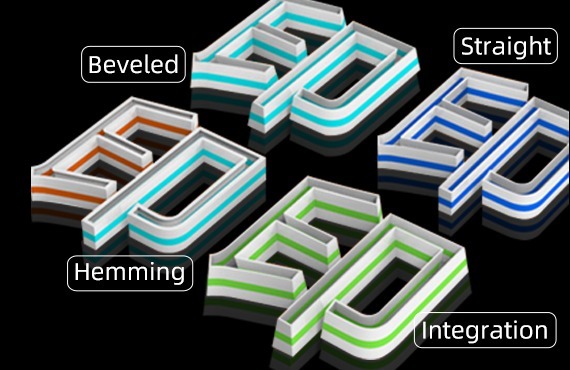

3 standardized processes make it easy to make letters.

Compared to mini luminescence word,the same investment, the income is tripled.

1 person controls 20 machines at the same time, the cost is reduced by 50%.

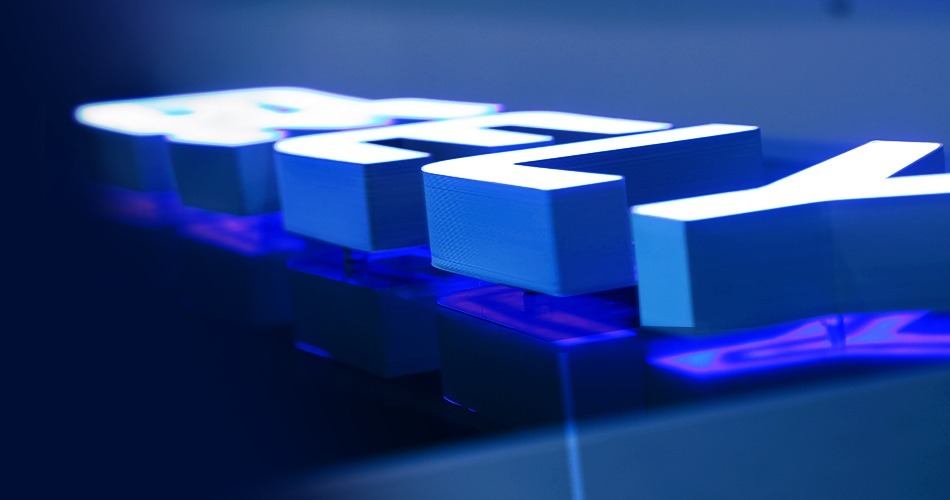

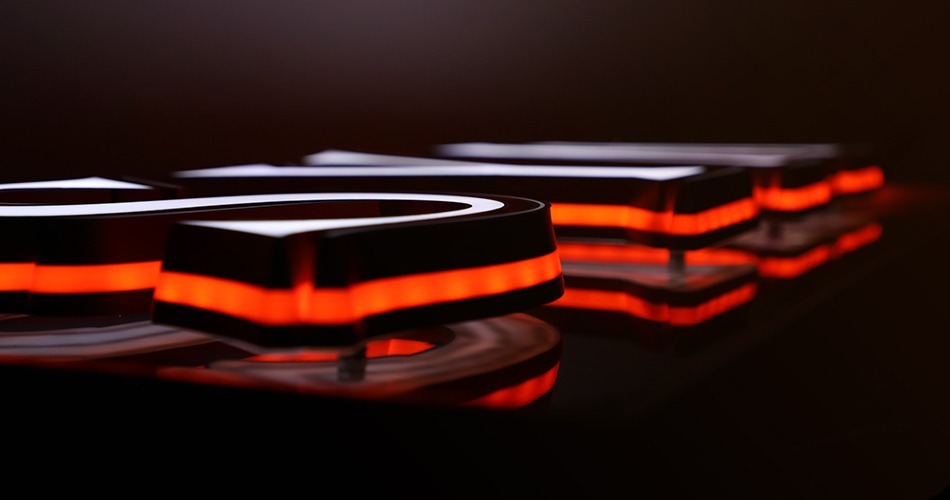

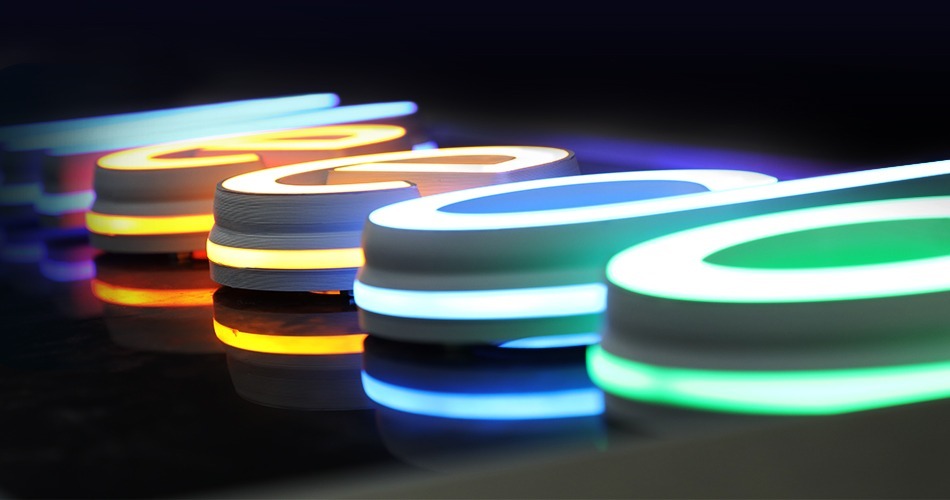

8 kinds of side shapes + N kinds of panel crafts + 4 ways to light up

| K8 Channel Letter 3D printer Parameters | |

|---|---|

| Molding tech | FDM (Fused Deposition Molding) |

| Printing Size | 800*800*85mm |

| Machine Size | 1222*1130*700mm |

| Operation speed | ≤150mm/s |

| Printing Filament | PETG |

| Hotbed Temp | ≤65°C |

| Nozzle temperature | ≤260°C |

| Print layer thickness | 0.1-0.6mm |

| XY-axis accuracy | ≤0.05mm |

| File Transfer | SD Card |

| Operation System | Win10/Win8/Win7 |

| Language | Chinese/English |

| Slicer software | PioCreat AD |

| Power Requirements | AC100- 220V |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

3D printer PETG filament with high purity, no bubbles, no jamming, no warping, melt well, feed smoothly, outstanding 3D printing appearance. 100% no tangle, machine auto wind, fixed hole steady, perfectly compatible for channel letter 3D printer.

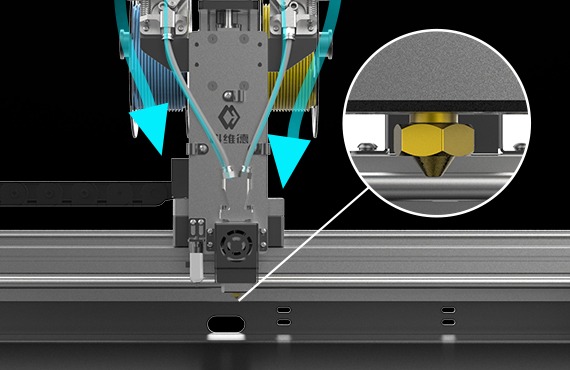

Multi-point detection, inteligent compensation easy Installation, strong compatibility.

Uniform filament output, temperature and abrasion resistance, easy replacement.

High temperature resistant alloy to ensure constant temperature of the nozzle

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.