Table of Contents

What is An Industrial 3D Printer?

An industrial 3D printer is a high-capacity device used for additive manufacturing in sectors like aerospace, healthcare and automotive. Using digital blueprints, they build objects layer by layer from various materials, including metals, polymers, and plastic pellets. They offer precision, scalability, customization, and can promote material efficiency. Despite their high price, benefiting from reduced waste and optimized production processes.

Applications of Industrial 3D Printers

Industrial 3D printing for Aerospace

In the Aerospace industry, industrial 3D printing has improved efficiency drastically. It excels especially in low-volume production requirements that are typical for aviation, allows huge weight reductions with potentials to design lighter yet strong parts, enables part consolidation by creating singular complex parts instead of multiple ones that need to be assembled, and aids in maintaining and repairing components, thus extending their lifespan and thus reducing costs.

Industrial 3D printing for Automotive

The Automotive industry benefits substantially from higher speeds in product development, since it enables rapid production of prototype parts for testing and feedback loops. Equally notable is the opportunity it offers for design flexibility and creativity for developing parts that were previously unthinkable or impossible to manufacture. Industrial 3D printing facilitates customization, letting manufacturers provide personalized designs and systems. Lastly, it allows for the implementation of intricate geometries which would normally be challenging or costly using traditional manufacturing methods.

Industrial 3D printing for Manufacturing

In the broader field of Industrial manufacturing, industrial 3D printing provides advanced design complexities not achievable through casting or machining, enhancing product functionality and efficacy. This technology makes for substantially shorter lead times by eliminating the necessity for specialized tooling or fabrication processes. With on-demand production made possible, inventory control is improved as only the necessary parts are manufactured when required, reducing storage needs and upfront production costs.

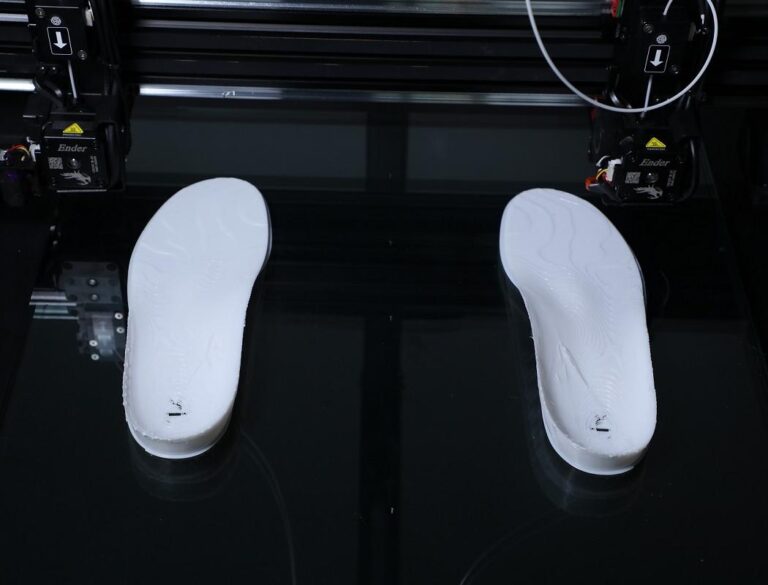

Pellet 3d printer - a Breakthrough in 3D Printing Technology

Granule printing, or Fused Granular Fabrication (FGF), has long been a staple in industrial printing due to its cost-effectiveness. For a wide range of applications, 3D printing with pellets and shredded recycled plastic is a financial and environmental win-win.

G5Ultra Industrial FGF Pellet 3D Printer

G5Ultra Pellet 3D Printer, a compact yet industrial-capable desktop device for quality 3D printing. It offers a large printing size, suitable for enthusiasts, professionals, and entrepreneurs seeking easy, speedy, and cost-effective design transformation. Its key characteristic is a high-power nozzle, reaching 420℃, ensuring excellent result quality and particle precision.

Its unique quick discharge feature allows easy material removal and cleaning, fostering user comfort. It supports a variety of thermoplastic pellet materials, including PA-CF, PA-GF, PC-CF, PLA and rPLA, promising unrestricted creativity. The G5Ultra: Your efficient, low-cost industrial 3D print solution.

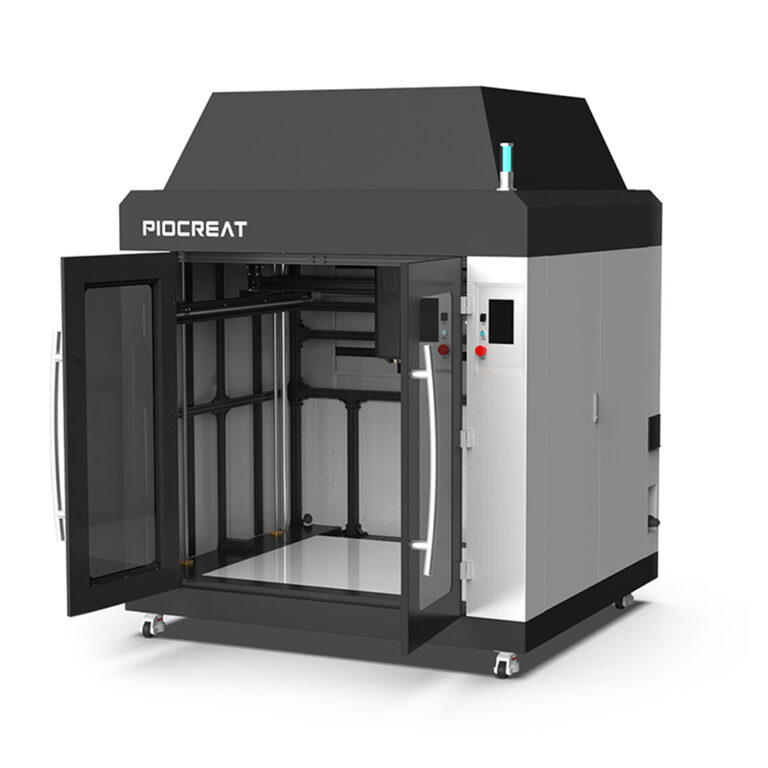

G12 Industrial FGF Pellet 3D Printer

The G12 Pellet 3D Printer delivers advanced manufacturing with an impressive build volume, making it a powerhouse for producing medium-to-large scale parts for various industries including automotive, aerospace, art, and furniture. The G12 exemplifies versatility in handling different materials with its high nozzle temperatures, focus on structural integrity through a unique screw extruder design, rapid-heating bed to speed up production times, and a specially designed servo motor for precision.

With these features, G12 opens innovative possibilities beyond traditional manufacturing constraints, encouraging limitless creativity within the industrial landscape. Adopt the G12 and reshape the future of additive manufacturing.

G40 Additive And Subtractive Manufacturing Integrated Machine

The G40 Pellet 3D Printer features a large build volume (3725x2500x1330mm) suited for any large-scale project. Its split workbench has six distinct heating zones, providing customizable heating and maximizing energy efficiency. Its powerful, German-made 8.5KW/24000 CNC five-axis head enables precise processing of materials like carbon fiber and plastics.

The high-speed extrusion system manages a swift print speed of 10m/min without compromising precision. These features make the G40 ideal for industries like automotive and aerospace, offering effective, precise, and efficient large-scale production merits. Its blend of additive and subtractive manufacturing abilities underlines this cutting-edge machine’s capabilities.

In Conclusion

Industrial 3D printers revolutionize manufacturing by creating complex parts, prototypes, and tools. They’re quintessential in sectors like aerospace, healthcare, and automotive for customizations and supply chain efficiency. Moreover, they facilitate on-demand production, waste reduction, and breakthrough advancements in biomaterials and sustainability.