The orthotics and prosthetics (O&P) industry is undergoing a digital revolution, with 3D printing emerging as a transformative force. By combining precision engineering, biocompatible materials, and simplified workflows, additive manufacturing offers new ways to create customized medical devices that improve patient comfort, functionality, and quality of life.

This blog explores how 3D printing is being applied across orthopedics, the benefits it delivers, and how PioCreat’s latest printer solutions are designed to meet the unique demands of the O&P field.

How Is 3D Printing Used in Orthopedics?

3D printing has expanded into nearly every area of orthotics and prosthetics. Below are some of the most common applications:

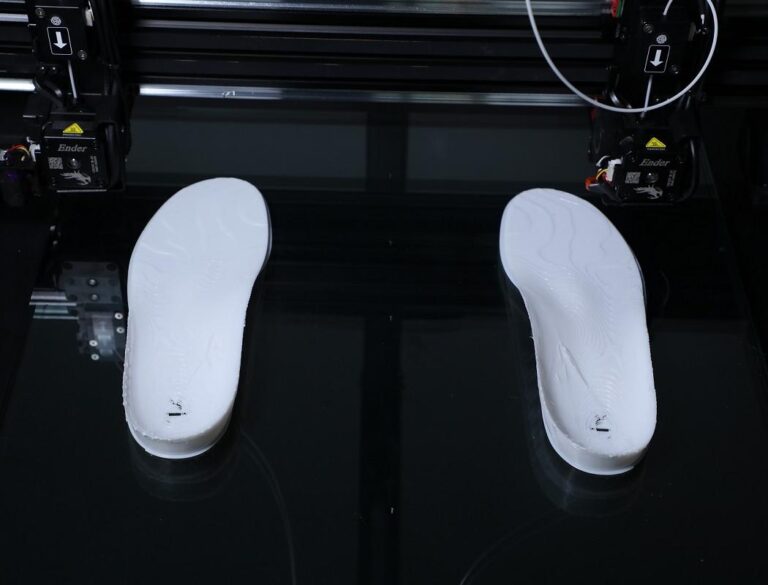

Insoles

3D-printed insoles allow for precise customization, tailored to the exact shape of a patient’s foot. Clinicians can design insoles with varying hardness levels, arch support, and ventilation structures, creating personalized solutions for foot pain relief and long-term orthopedic support.

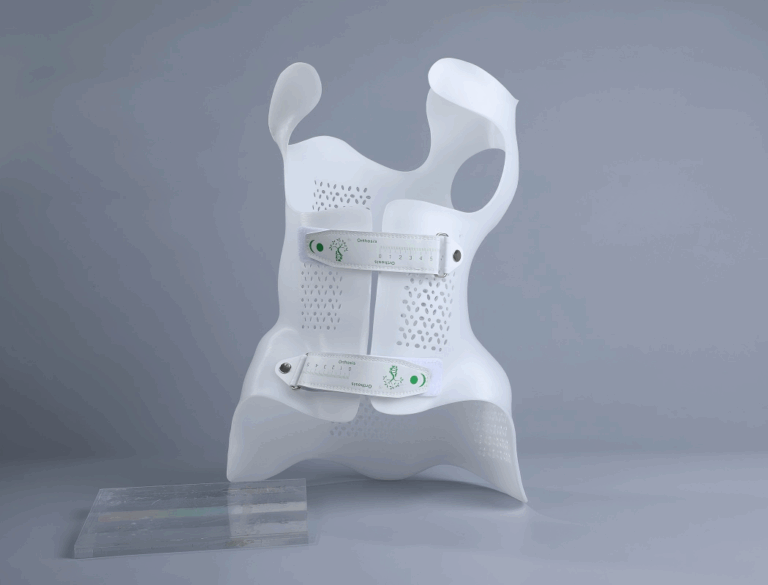

Scoliosis Braces

Traditional scoliosis braces are bulky and time-consuming to manufacture. With 3D printing, braces can be lighter, more breathable, and anatomically accurate. Patients benefit from greater comfort and compliance, while clinics streamline their production process.

Prosthetic Sockets and Covers

A prosthetic socket is the most critical interface between a patient and their prosthesis. 3D printing ensures sockets are highly accurate and contoured to each patient’s anatomy, reducing the risk of pressure points. Custom cosmetic covers can also be printed to restore confidence and individuality.

Cranial Remolding Helmets

For infants with plagiocephaly, 3D printing allows for lightweight, breathable cranial helmets designed with exact cranial geometry. These helmets provide effective correction while ensuring comfort during critical growth phases.

Wrist and Hand Orthoses

Additive manufacturing enables the creation of lightweight and functional hand and wrist supports, providing stability and mobility while allowing breathable, open designs for improved patient compliance.

What Are the Benefits of Using 3D Printing in Orthotics & Prosthetics?

Sustainability

Traditional O&P manufacturing can be wasteful, with large amounts of excess material. 3D printing optimizes material usage, reducing waste and promoting more sustainable clinical practices.

Cost Savings

By eliminating the need for expensive molds, casts, and manual labor, 3D printing lowers production costs. Clinics can reinvest these savings into patient care or new technologies.

Simplified Workflow

Digital workflows—from scanning to design to print—remove the complexity of manual processes. This allows clinicians to easily adjust designs and iterate quickly without starting from scratch.

Time Savings

What once took weeks can now be completed in days. Patients benefit from faster device delivery, while clinics improve efficiency and capacity.

Printing Materials for Orthotics & Prosthetics

Material selection is critical for producing safe, effective, and durable O&P devices.

PP Composite for Scoliosis Braces

Polypropylene (PP) composites provide a balance of durability and flexibility, essential for scoliosis braces that must endure repeated wear. PioCreat’s PP composite has passed rigorous testing, including 5,000 opening and closing cycles, ensuring long-term performance in clinical use.

TPU for Insoles

Thermoplastic polyurethane (TPU) is widely used for insoles thanks to its flexibility, comfort, and shock absorption properties. TPU also allows for design variations in hardness, enabling clinicians to fine-tune insoles for different patient needs.

3D Printers for Orthotics & Prosthetics

PioCreat has developed specialized 3D printing solutions tailored to the O&P industry, ensuring clinicians and manufacturers have access to systems designed for medical applications.

MS01 SE: High-Temperature Pellet 3D Printer

The MS01 SE is the latest addition to PioCreat’s portfolio, specifically optimized for orthotic applications such as scoliosis corsets. With an industrial-grade nozzle temperature of up to 400°C, it can process advanced medical-grade polymers like PP composites. The large build size of 650mm ensures full-size brace production in one print. By removing unnecessary components for this focused application, the MS01 SE offers stable, reliable performance ideal for clinical environments.

IPX2: Special 3D Printer for Custom Insoles

The IPX2 is a dedicated solution for podiatrists and orthopedic shoe technologists. It combines materials, hardware, and software into one streamlined system, making it simple to produce custom insoles in-house. This reduces outsourcing costs, shortens turnaround times, and ensures patients receive precisely fitted insoles quickly and affordably.