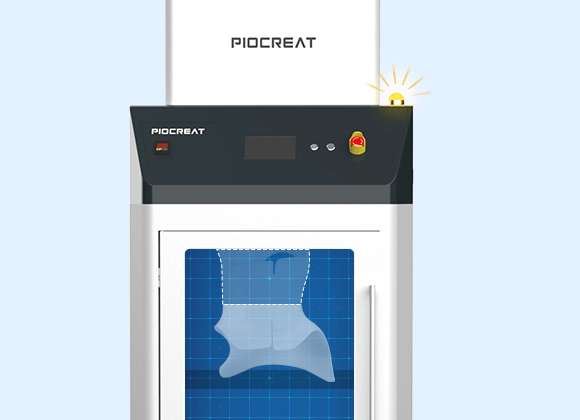

The MS01 High-Temperature Pellet 3D Printer is the latest addition from PioCreat. With an industrial-grade nozzle temperature of up to 400°C and a part size of up to 650mm, this printer delivers maximum performance for engineering materials, all produced using industry-standard pellets. It is ideal for prosthetic and orthotic applications, ensuring optimal support and comfort, such as scoliosis corsets.

This feature ensures a constant temperature working environment, crucial for achieving superior molding effects. It helps maintain stable conditions for high-temperature materials, ensuring consistent print quality throughout long operations.

Equipped with a robust nozzle that supports temperatures up to 400°C, this printer can handle a vast range of materials, from standard filaments to advanced composites, facilitating diverse project requirements.

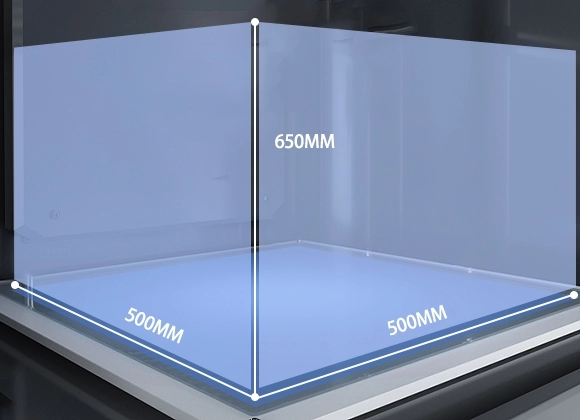

The generous build volume of 500×500×650mm allows for large-scale projects, ranging from bulky prototypes to substantial production parts, expanding the realms of possibility in 3D printing.

An intelligent feature that ensures continuous printing by detecting material breaks. This feature allows for the addition of pellets mid-print without interruption, significantly enhancing productivity and reducing downtime.

| MS 01 FGF Fully Enclosed 3D Printer Parameters | |

|---|---|

| Moldingt echnology | FGF |

| Print size | 500×500×650mm |

| Print layer thickness | 0.5-1.5mm |

| Printing accuracy | 100土0.1mm |

| Printing material | High temperature composite materials |

| Nozzle temperature | ≤400°C |

| Heating bed temperature | ≤110°C |

| Number of nozzles | 1 |

| Nozzle diameter | 1.0mm(2.0,3.0,4.0mm optional) |

| Particle diameter | 2-5mm |

| Discharging mechanism | Screw extruder |

| Slicing software | Plocreat slicer |

| Rated power | 4200W |

| Power requirements | 100-120V~,200-240V~,50/60Hz |

| N.W. | 274KG |

| G.W | 324KG |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

Three-dimensional scanning completely avoids the shape-taking errors caused by traditional plaster negative and positive molds, captures a high-precision three-dimenonal data model of the human body, and perfectly matches the X-ray film.

cases

3D printing integrated molding, high plasticity, providing good correction effect.

Full-body breathable design, 50% hole design,Breathable and comfortable

Improved Cheneau brace, with partially unequal thickness design, the thickness is reduced by 20%,and the average weight is only about 530g.

Customized hole patterns Customized signature

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.