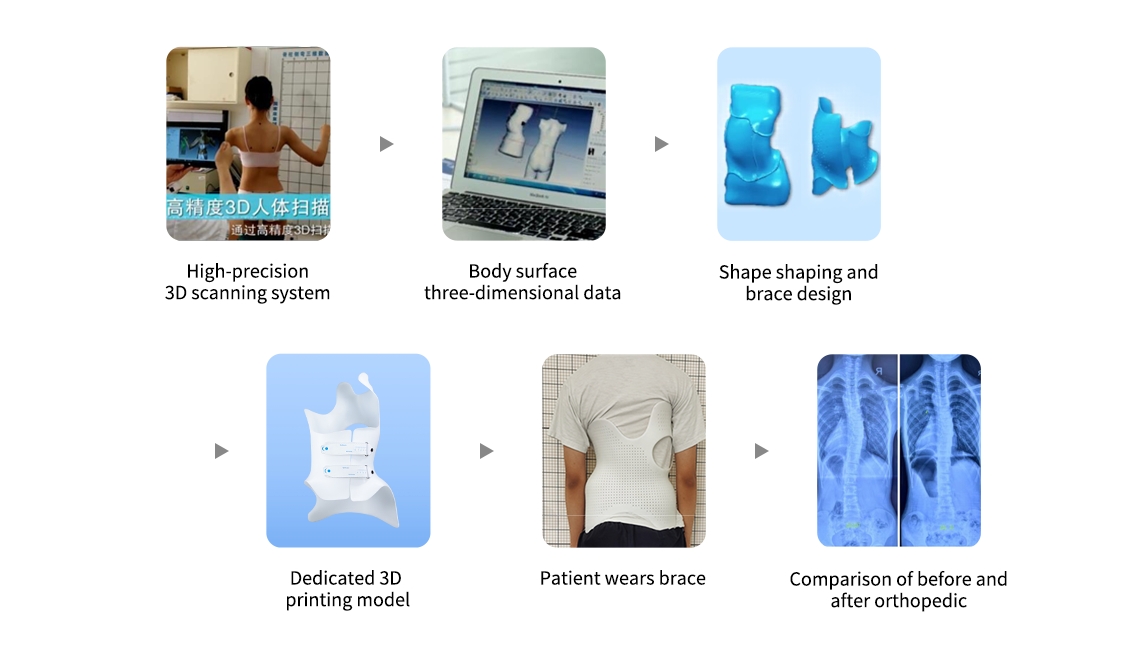

Grow your business with customized 3d printed scoliosis brace designed to help enhance patient comfort.

Crafted from lightweight materials, these braces ensure ease of movement without compromising support or structural integrity.

Designed with digital spine scans, braces perfectly contour to the patient’s body for optimal fit and effectiveness.

Engineered with breathable materials, they enhance comfort and promote long-term wearability for better treatment adherence.

Customizable designs allow patients to choose unique styles, ensuring both functionality and a confidence-boosting look.

The CR-Scan Otter is a portable handheld 3D body scanner featuring next-generation four-eye infrared structured light technology. It captures highly accurate human body data models, enabling precise alignment with X-ray images.

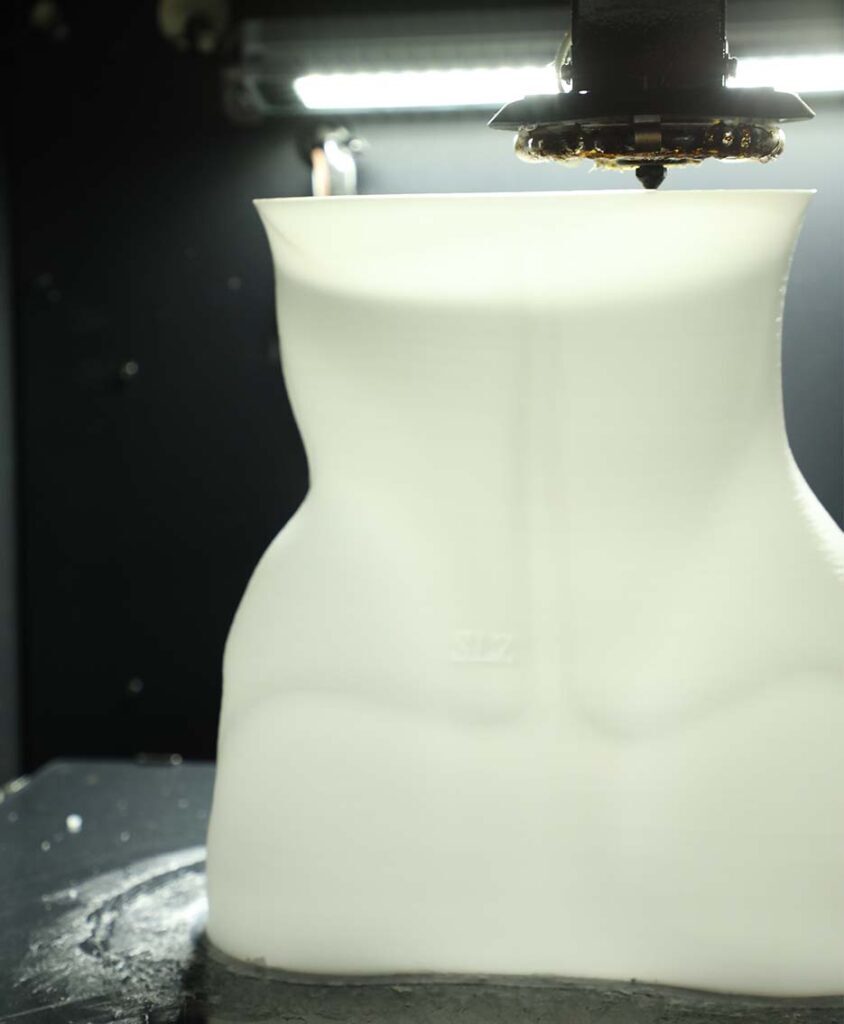

MS 01 3D Printer offers a wide selection of high temperature composite materials. You’ll combine fast and easy material swaps, a generous build volume, and dependable print results to provide accurate, repeatable 3D printing.

Durablity & Flexibility – Our PP composite has successfully passed 5,000 opening and closing cycles in testing.

Excellent Reformability– This feature allows clinicians to make precise adjustments to suit the patient’s needs, improving long-term comfort.

Lightweight Design– The PP composite’s low density makes spinal braces lighter, offering improved comfort and easier movement for patients.

Typically, printing a scoliosis brace takes between 5 and 8 hours, depending on the design and material specifications.

Yes! We provide comprehensive online support and training to ensure you can operate the equipment and system with confidence. Our team will assist you until you feel fully comfortable using the printer independently. We’re here to support you every step of the way.

Currently, the MS01 is primarily used for printing scoliosis braces. We are in the process of evaluating its suitability and regulatory compliance for other prosthetic and orthotic (P&O) devices. Once we have confirmed results, we will update you promptly.

Absolutely. Our software comes with lifetime free updates. As we enhance print speeds and introduce new functionalities, you will always have access to the latest version — at no additional cost.

The equipment includes a 1-year warranty, during which we provide free maintenance and technical support. We also offer guidance on routine maintenance to help ensure optimal performance and extend the life of your machine.

Explore our 3D printing technology to find the right solution for your business

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.