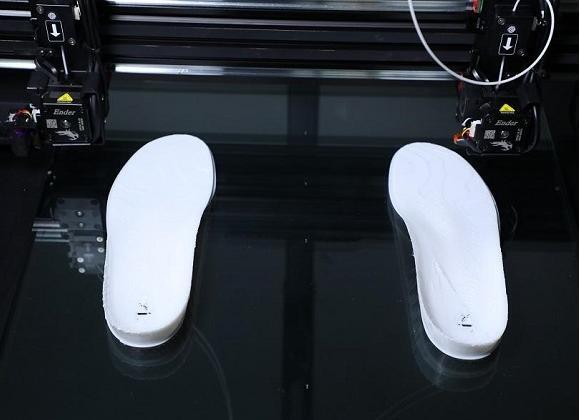

IPX2 offers an easy-to-use 3D printing solution for custom-made insoles, integrating materials, hardware, and software effectively. This system allows precise, affordable orthotic insole production with reduced costs and labor. Ideal for podiatrists and orthopedic shoe technologists, it enhances turnaround times and customer comfort, streamlining in-house custom orthotic production.

| IPX2 FDM 3D Printer Parameters | |

|---|---|

| Molding technology | FDM |

| Print size | 190×320×200mm |

| Printing speed | ≤180mm/s |

| Printing accuracy | ±0.1mm/100mm |

| Layer thickness | standard 0.4mm(0.6,0.8mm optional) |

| Number of nozzles | 2 |

| Nozzle diameter | 0.8mm(.0.4.0.6mm optional) |

| Nozzle temperature | ≤300°C |

| Rated power | 150W |

| File format | STL, OBJ, Gcode |

| Connection method | USB disk, WIFI |

| Slicing software | Plocreat_slicer |

| Operating system | WIN, MAC, Linux |

| Machine size | 730×540×490mm |

| Support material | TPU-95A/90A/85A/80A,TPE-83A |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.