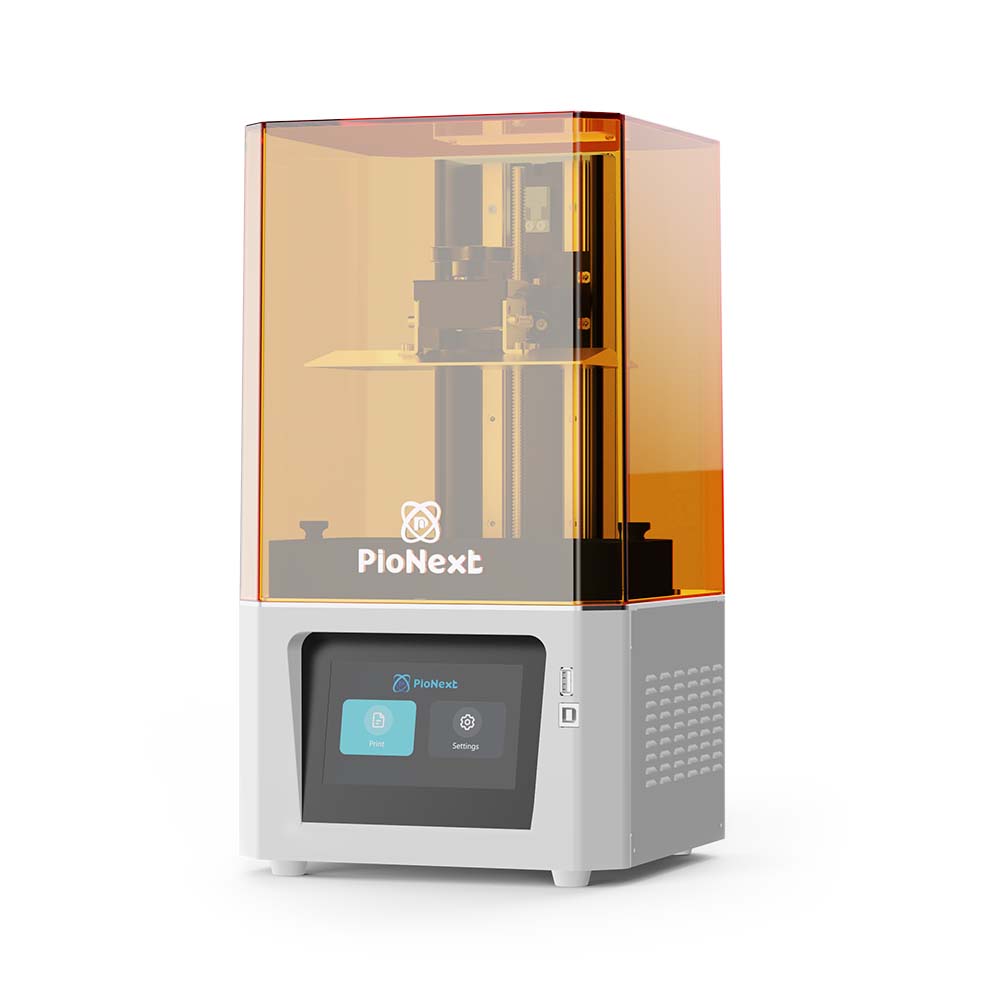

Top cost-effective resin 3D Printer for dental and jewelry industries with 8K 10.3″ LCD for unmatched print clarity and detail.

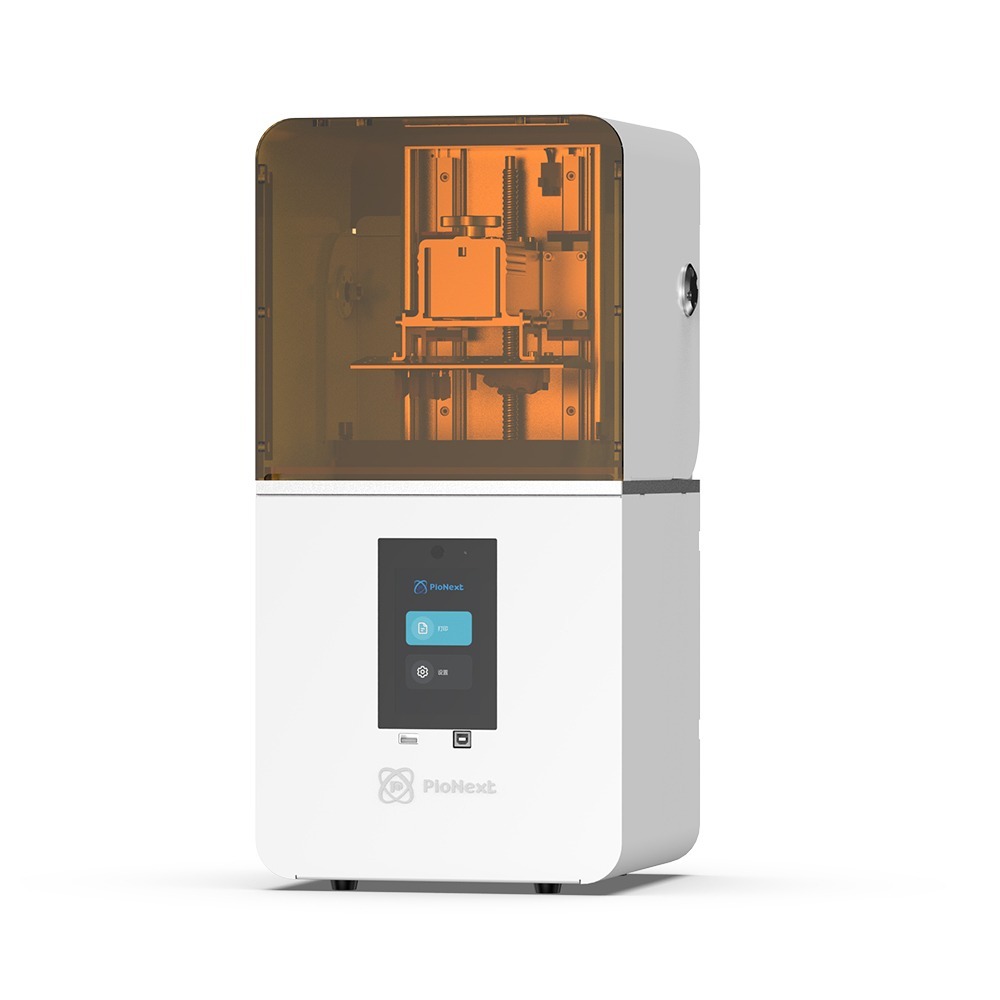

The D158 is a compact DLP 3D printer for dentistry, offering precision and reliability with features that simplify printing for dental labs, orthodontics, and practices.

D150 excels in dentistry and more with unmatched productivity, adjustable light intensity: 6000-20000uw/cm2, ensuring quick, high-quality prints for professionals.

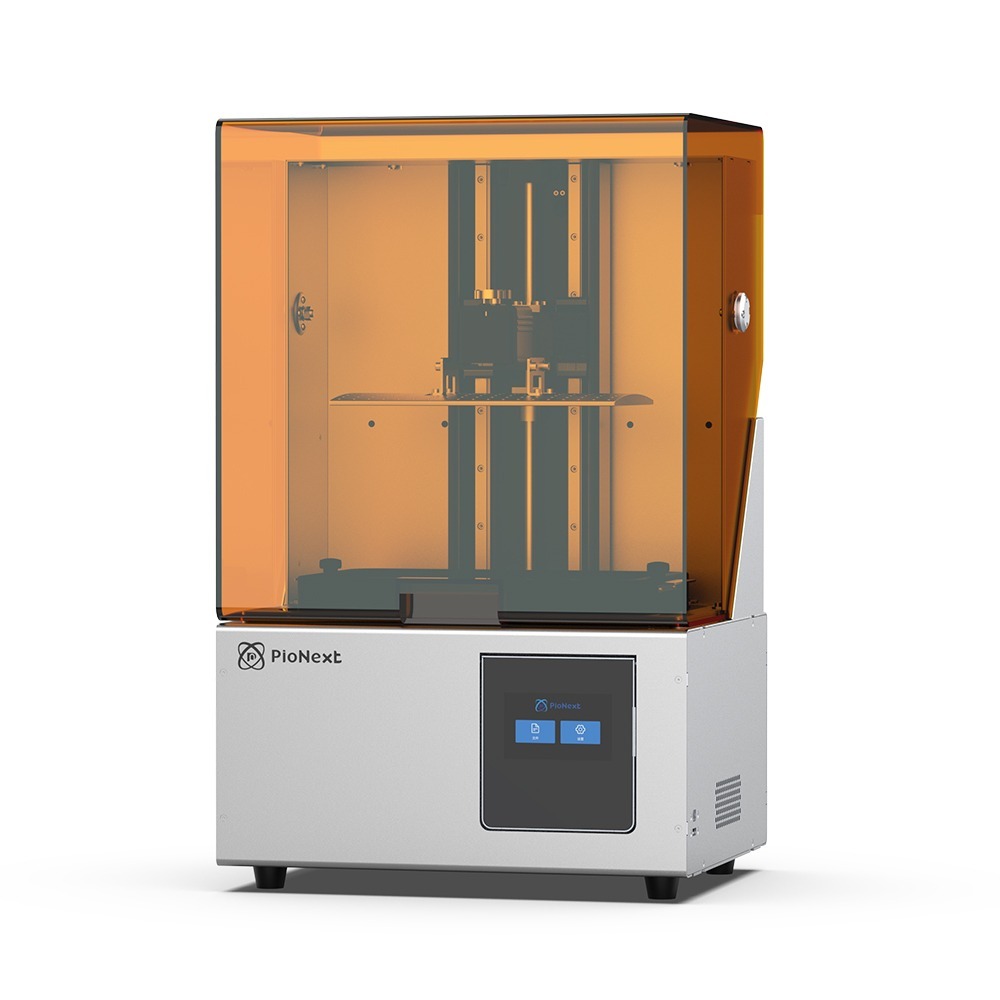

The D190 3D Printer offers high-precision 4K DLP tech for detailed prints, ideal for intricate dental models, temporary crowns, surgical guides, and orthodontic models.

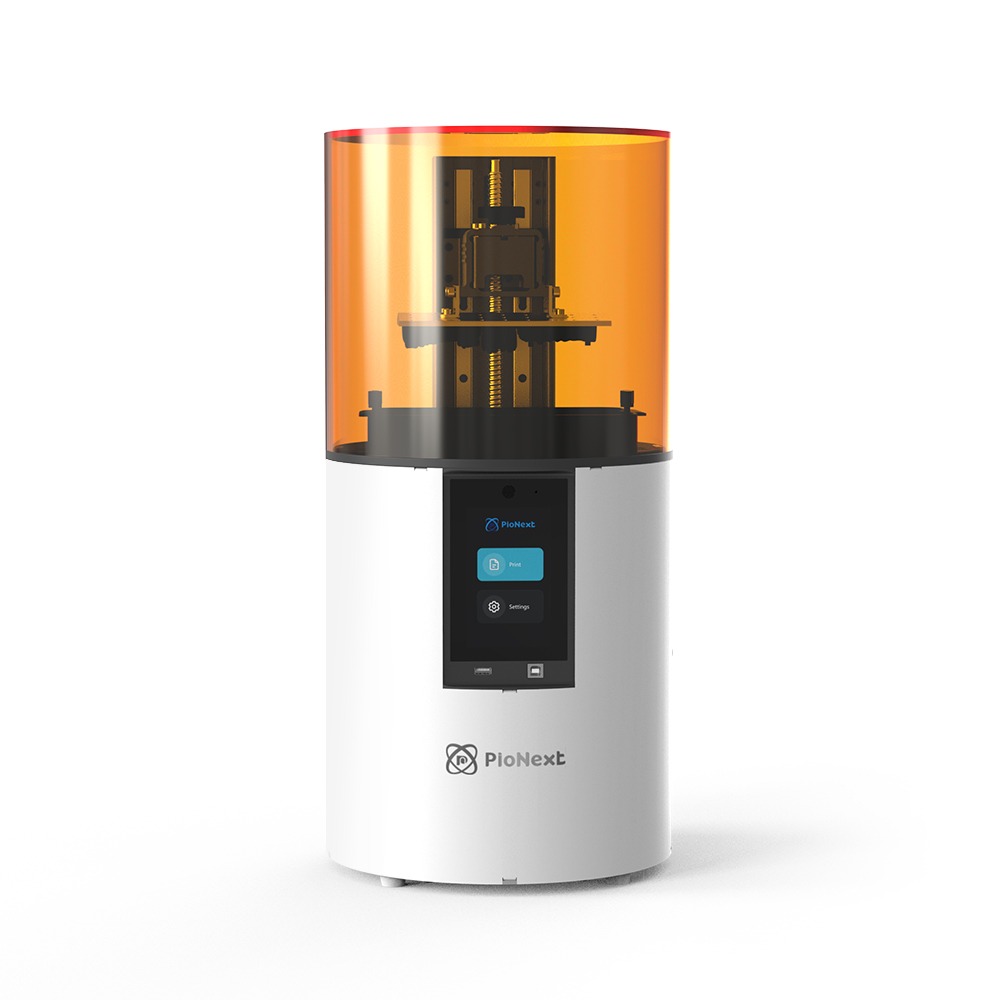

PioCreat’s largest LCD 3D Printer excels in producing dental prosthetics, intricate jewelry, and industrial parts with high precision, meeting diverse application requirements.

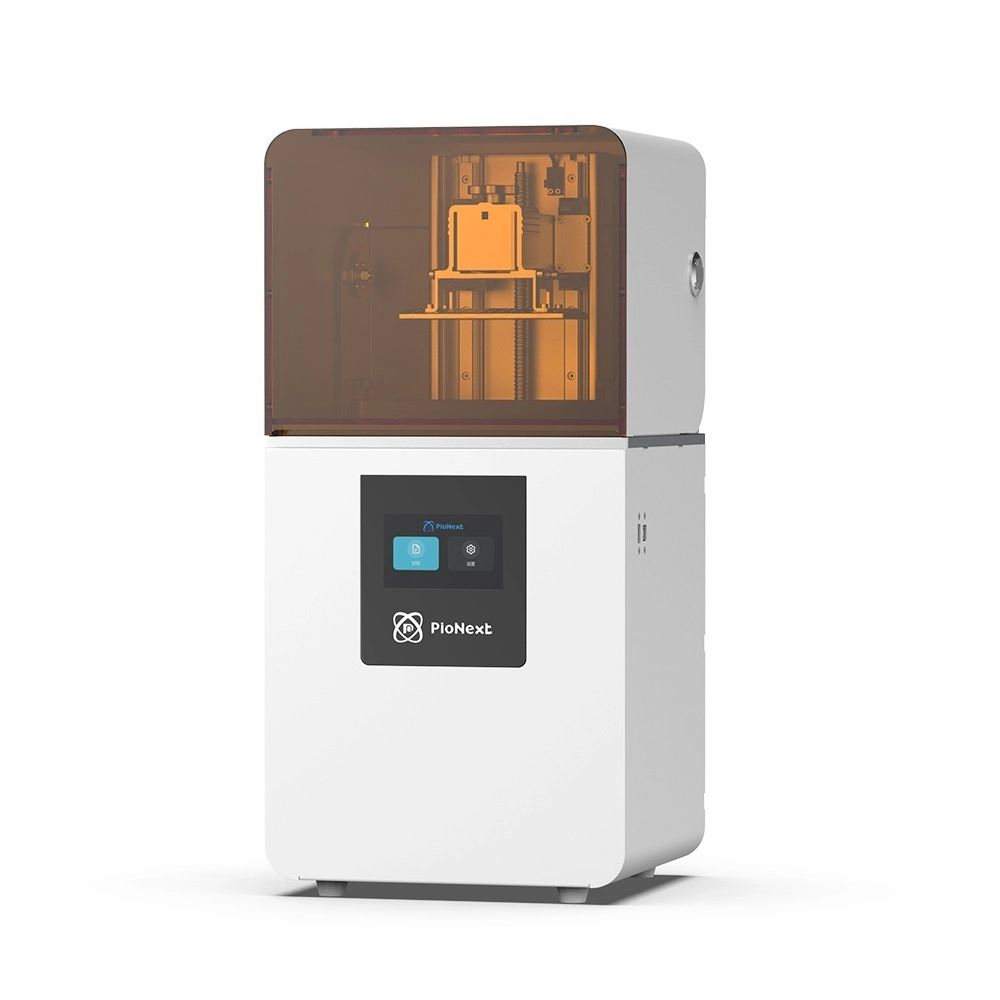

The D160 DLP 3D Printer, ideal for dental professionals, offers high quality in a compact, easy-to-use design with minimal upkeep, perfect for both experienced and novice users.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.