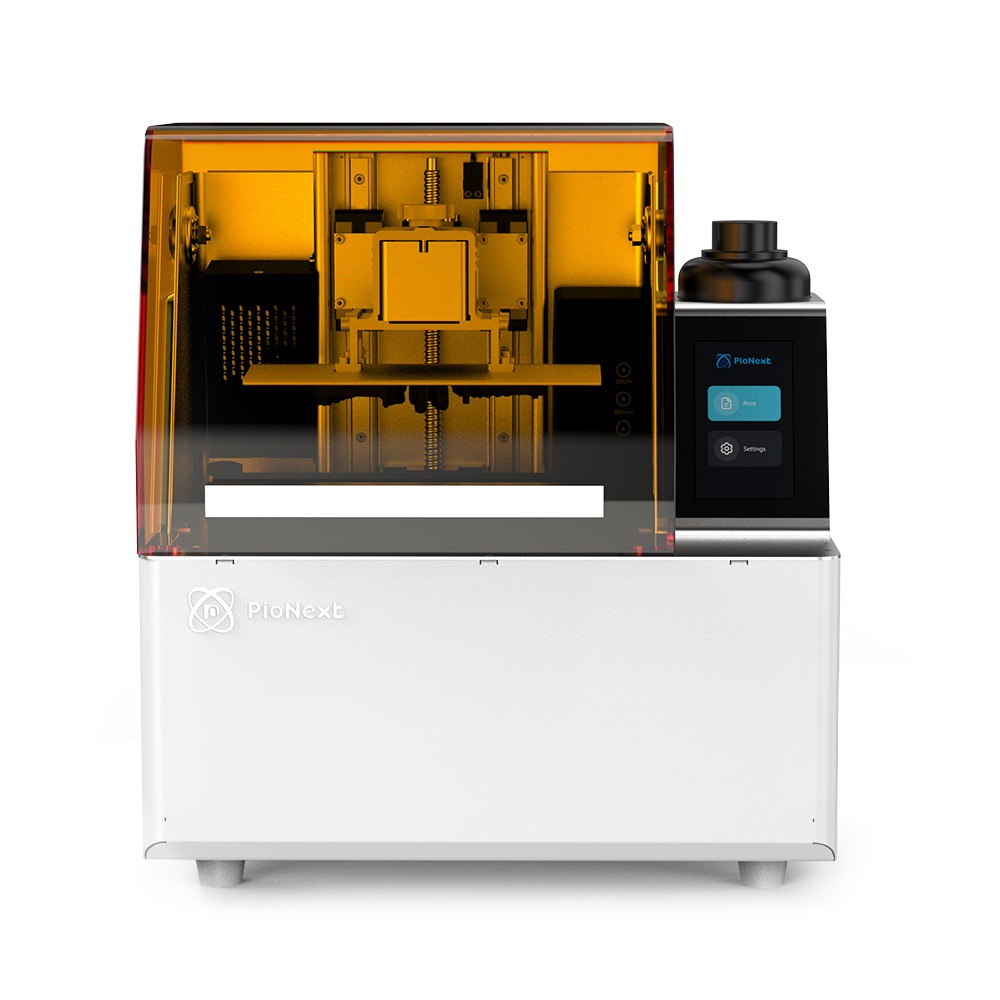

The pinnacle of precision and reliability for dental and jewelry professionals seeking cost-effectiveness without compromising on quality. This state-of-the-art 8K LCD 3D printer has been specially designed to cater to the intricate needs of high-detail fabrication, offering an array of features that ensure unparalleled results.

The DJ89 PLUS features a 29μm pixel size and 10.3-inch 8K LCD, ensuring sharp, detailed sculpting for dental and jewelry designs. Its high-resolution capabilities accurately capture every design nuance, ideal for complex dental structures or intricate jewelry, enhancing precision and detail quality.

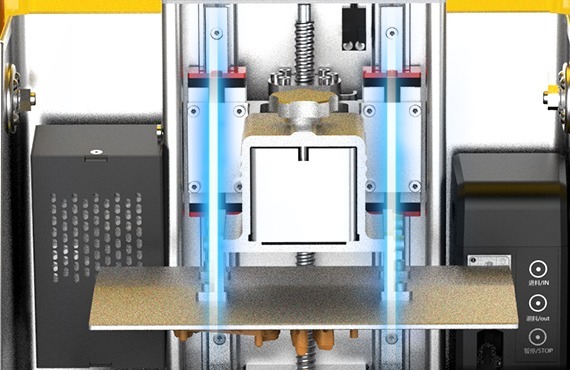

The DJ89 PLUS excels with its integrated heating chamber, keeping the temperature between 20-35°C to maintain resin viscosity for flawless prints. This ensures minimal warping and imperfections, promoting a smoother post-processing experience by providing optimal printing conditions.

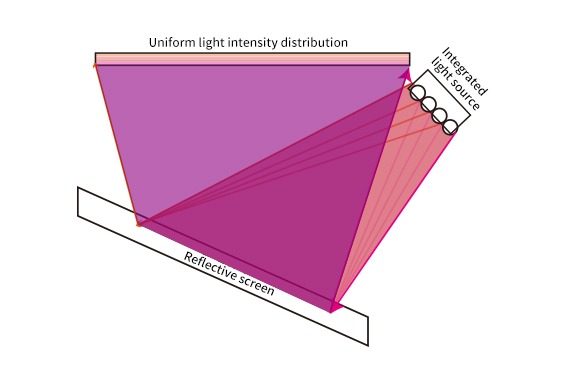

The DJ89 PLUS incorporates a unique light source merging DLP and LCD technologies, distributing LED light evenly across the LCD via reflection. This creates a uniform light source with up to 95% uniformity, ensuring consistent exposure for each print. The outcome is cost-effective, high-quality output competitive with pricier DLP printers.

The DJ89 PLUS sports a strong Z-axis with dual linear guide rails and a precision ball screw, ensuring smooth vertical movements and minimal Z-wobble. This enhances surface finish and accuracy, crucial for dental and detailed jewelry applications where precision is key.

PioCreat's printers offer fast, accurate, and clear printing with quick print times and a high success rate.

PioCreat devices print with high resolution to improve the dimensional precision of each item.The specially formulated.

PioCreat's products incur lower ownership costs, producing more items with less material compared to competitors.

Engineered for simplicity, our printer ensures easy setup, effortless use, and minimal maintenance, ideal for both experts and 3D printing novices.

| DJ89 PLUS 3D Printer Parameters | |

|---|---|

| Molding tech | LCD |

| Printing Size | 228x128x100mm |

| Machine Size | 450x290x500mm |

| XY axis accuracy | 29μm |

| Print speed | 60mm/h |

| Print layer thickness | 0.01-0.1mm |

| Printing screen | 10.3 inch, 8k monochrome |

| Resolution | 7680*4320 |

| Z-axis type | double linear guide + ball screw |

| LCD screen life | 2000 hours |

| Anti-aliasing | 8 times anti-aliasing |

| Automatic leveling | support |

| Automatic feeding: | support |

| Molding chamber heating | support(Temperature range 20-35°C) |

| Slicer software | PioCreat Box(Win7 or above X64,Mac) |

| Power Requirements | AC100-240V |

| Material Compatibility | Enjoy a limitless selection of top materials |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

A portfolio of state-of-the-art dental resins to create products characterized by their robustness, minimal shrinkage, strong biocompatibility, and resistance to wear.

Less releasing resistance to speed up printing and improve printing success rate.

Built-in liquid level reminder to prevent waste caused by excessive dumping.

Rough oxidized sand-blasted surface enlarges contact for stronger adhesion.

Monochrome screen with highlight transmittance and long service life.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.