In the evolving field of orthotics and prosthetics, 3D printing technology is redefining how scoliosis treatment is approached. Traditional scoliosis braces, while effective, often suffer from limitations in fit, comfort, and customization. Additive manufacturing introduces a powerful alternative—3D printed scoliosis braces—which promise not only better patient outcomes but also greater efficiency for medical equipment manufacturers and orthopedic professionals.

Precision Engineering with 3D Printing in Scoliosis Treatment

Scoliosis, characterized by an abnormal curvature of the spine, often requires long-term bracing, particularly in adolescents. Successful treatment hinges on three essential qualities: fit, comfort, and patient compliance. These are exactly where 3D printing excels.

With the integration of digital spine scanning and computer-aided design (CAD), orthopedic specialists can now create highly personalized orthotic braces tailored to each patient’s unique spinal anatomy. This not only enhances correction but also improves the patient’s willingness to wear the brace consistently.

The 3D Printed Scoliosis Orthotic Production Process

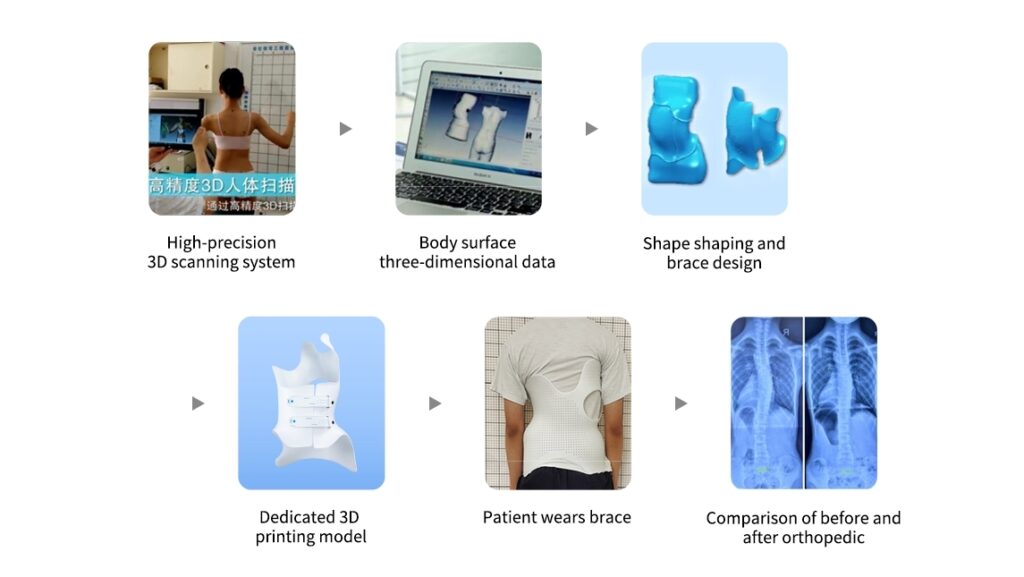

The workflow behind a 3D printed scoliosis brace combines digital precision with material innovation:

1. High-Precision 3D Scanning

A high-resolution 3D scanning system is used to capture the patient’s body surface geometry with accuracy. This replaces traditional casting, which can be time-consuming and prone to error.

2. Data Processing and Brace Design

Once the data is collected, software converts the three-dimensional body surface scan into a digital model. Orthopedic experts shape the brace around this model, factoring in corrective forces and patient mobility.

3. Dedicated 3D Printing

The design is then sent to a pellet-based 3D printer such as the MS 01 High-Temperature Pellet 3D Printer by PioCreat. It prints the brace using lightweight, engineering-grade thermoplastic pellets, precisely layering the structure to ensure strength, flexibility, and breathability.

4. Fitting and Adjustment

Once printed, the brace is fitted to the patient. Adjustments are minimal due to the custom nature of the process. Patients report a better experience from the start, thanks to the tailored fit.

5. Monitoring and Outcome Comparison

Orthotic teams document before-and-after results, noting spine correction progress and patient feedback on wearability, comfort, and aesthetics.

Key Benefits of 3D Printed Scoliosis Braces

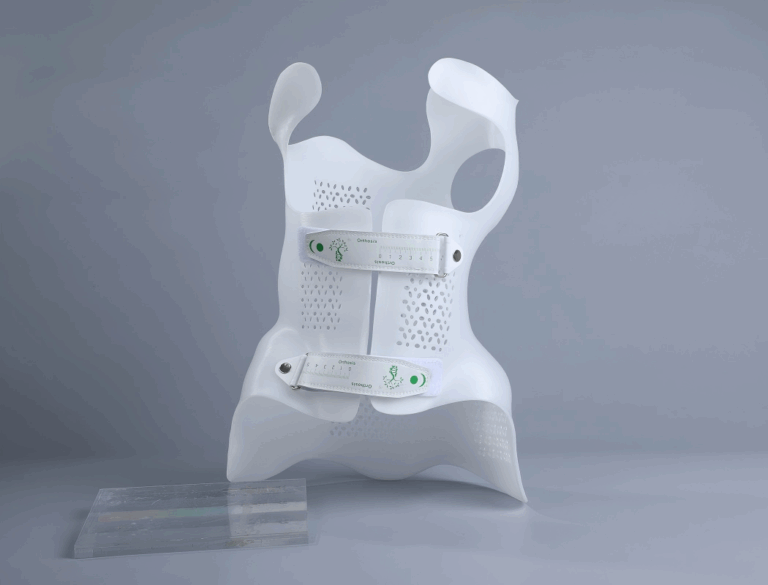

1. Lightweight Yet Durable

The braces are manufactured from advanced, lightweight thermoplastics, enabling patients to move freely without sacrificing the support needed for spinal correction. Lighter braces are also easier to wear under clothing and less tiring over long periods of use.

2. Close-Fitting Plasticity

Using exact 3D spine data, the brace contours closely to the patient’s body. This custom fit ensures effective corrective pressure while minimizing discomfort. Traditional braces, by contrast, often require multiple rounds of adjustments to achieve the same level of precision.

3. Breathable and Comfortable Design

Pellet 3D printing allows the creation of ventilation patterns and mesh-like structures within the brace, reducing heat build-up and skin irritation. This improves long-term wearability and helps patients adhere to prescribed brace schedules.

4. Personalized Aesthetics

Braces can be customized in style, shape, and even color, providing a much-needed psychological boost, especially for young patients. This personalization helps transform the brace from a stigmatizing medical device into a wearable piece of identity.

MS 01 Pellet 3D Printer: Engineered for Orthotic Applications

To meet the high standards of orthotic fabrication, PioCreat developed the MS 01 High-Temperature Pellet 3D Printer, optimized for printing with high-performance medical-grade materials. This system offers unmatched flexibility and production capabilities for clinics and device manufacturers.

Key Features:

Nozzle Temperature up to 400°C: Ideal for processing engineering thermoplastics like PA, TPU, and PETG with structural and functional integrity.

Large Build Volume: 500×500×650mm allows for full-size torso braces to be printed in a single piece, eliminating weak points from part assembly.

Fully Enclosed Chassis: Maintains a stable environment, ensuring dimensional accuracy and print quality even with high-temp materials.

The MS 01’s screw-extruder design enables the use of pellet feedstocks, which are more affordable and environmentally friendly than filament. Clinics and labs can reduce costs while expanding material options.

Why It Matters: From Clinic to Community

For prosthetists, orthotists, and healthcare providers, the shift toward 3D printed scoliosis braces brings multiple advantages:

Faster turnaround times with digital scanning and printing

Less material waste compared to subtractive methods

More comfortable and compliant patients, leading to improved clinical outcomes

Scalable production for both small clinics and larger medical manufacturers

As the field moves forward, digital orthotics fabrication will continue to set new standards in patient care and operational efficiency.

Looking Ahead

The integration of pellet 3D printing into orthotic production not only modernizes how braces are made, but it also empowers practitioners with new tools to deliver better care. With reliable hardware like the MS 01, supported by high-precision scanning and customizable design workflows, healthcare professionals can meet the growing demand for personalized, sustainable, and effective scoliosis treatment.

In a healthcare landscape increasingly focused on patient-centered design, 3D printed scoliosis braces are more than a technological upgrade—they represent a new standard in orthotic innovation.

Interested in learning more about how pellet 3D printing can improve orthotic outcomes? Contact us to explore how the MS 01 can elevate your practice.