Rethinking Scoliosis Orthosis: How 3D Printing Transforms Comfort, Precision, and Efficiency

piocreat3d

on

October 22, 2025

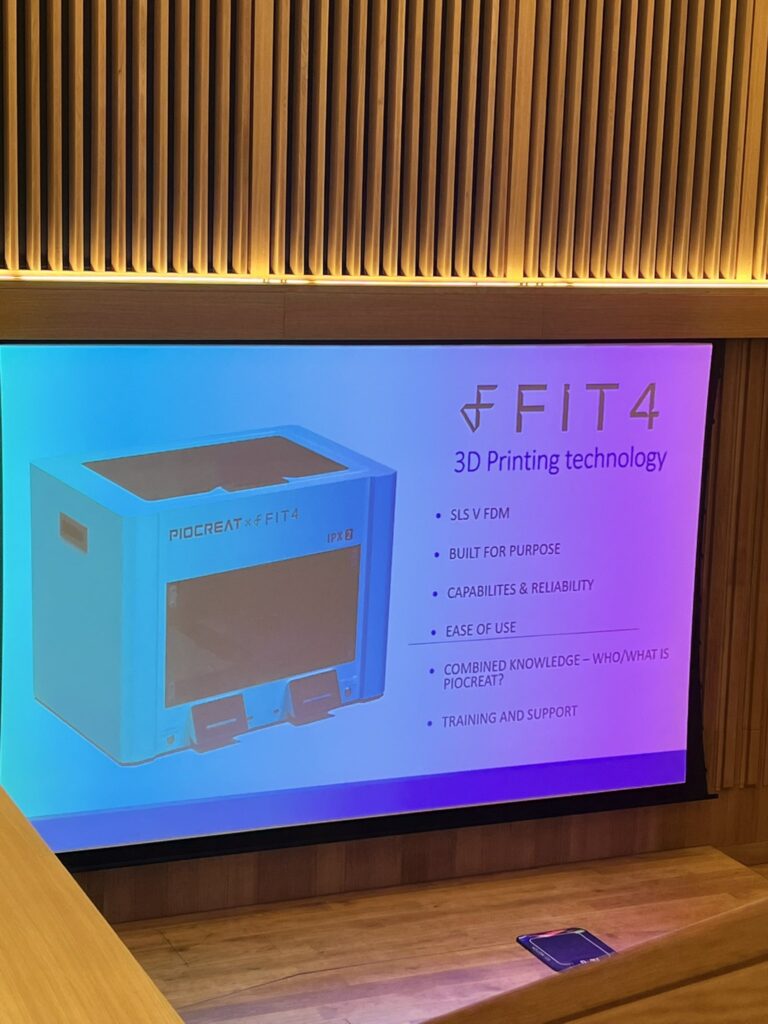

For decades, scoliosis orthoses have been fabricated using conventional plaster casting and manual molding techniques—a process that is time-consuming, labor-intensive, and often uncomfortable for patients. However, with the advancement of 3D printing technology, a paradigm shift is underway. At PioCreat, we are driving this transformation through advanced additive manufacturing solutions such as the MS01 SE 3D printer, engineered specifically for medical and orthotic applications.

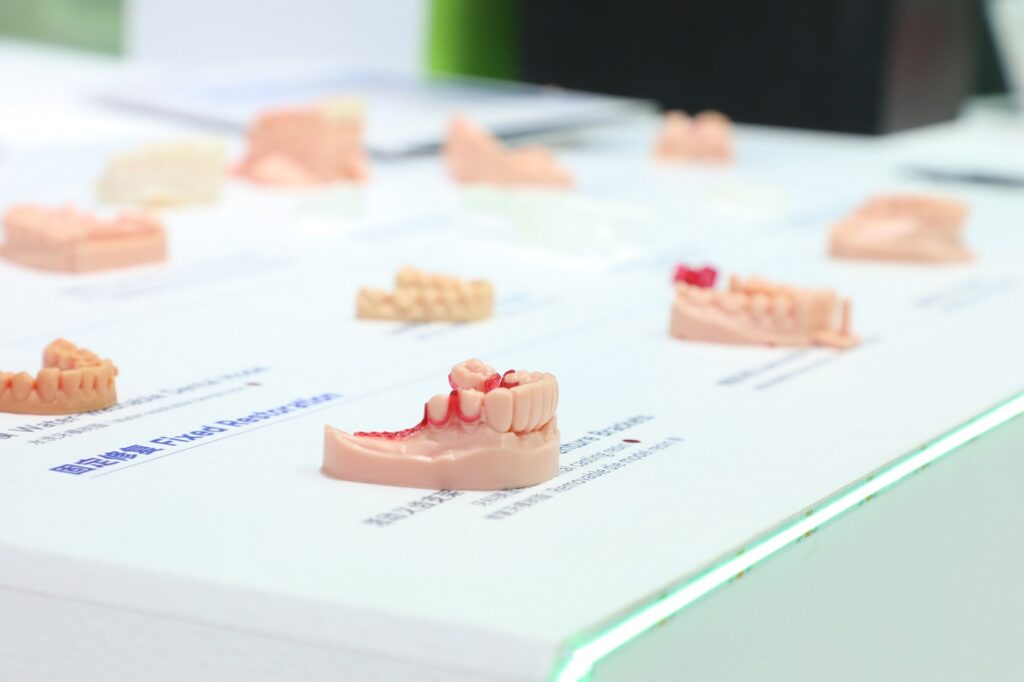

From Heavy and Rigid to Lightweight and Personalized

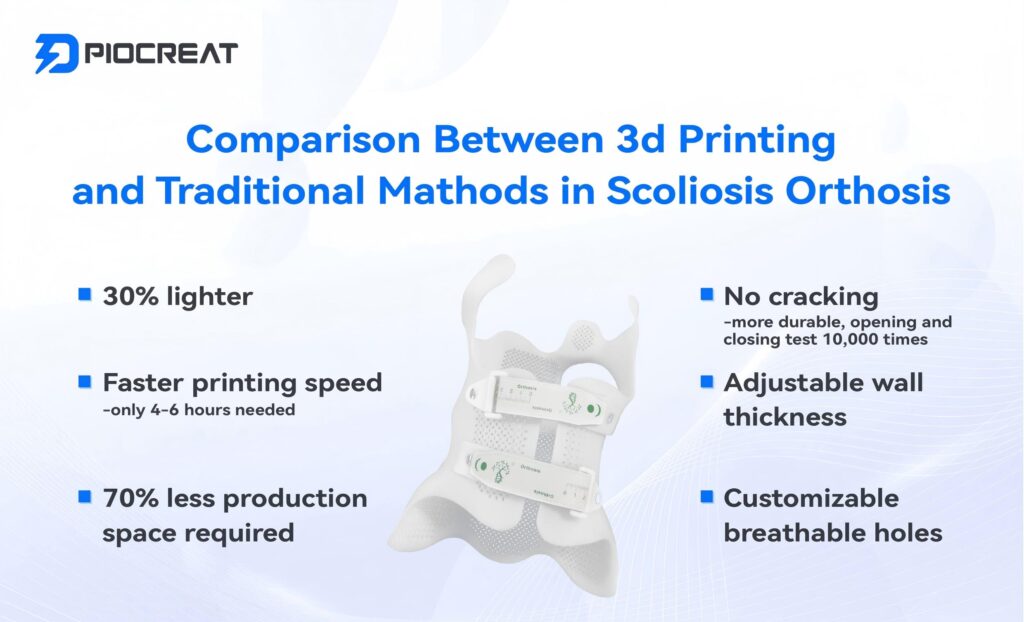

Compared with conventional methods, 3D-printed scoliosis braces are up to 30% lighter, significantly reducing the mechanical burden on patients—particularly adolescents who must wear the orthosis for extended periods.

Through digital design, clinicians can generate braces that conform precisely to each patient’s unique anatomy, improving not only corrective efficacy but also comfort, compliance, and long-term outcomes.

Faster, Cleaner, and More Efficient Production

Traditional brace fabrication requires highly trained technicians and extensive manual work — from mold casting and trimming to final fitting adjustments. Each step introduces potential for human error and variation in quality.

In contrast, 3D printing minimizes human error and reduces reliance on specialized labor. It allows clinics to produce accurate, repeatable orthoses with less training, less labor involvement, and significantly shorter production time, streamlining operations while ensuring consistent clinical outcomes.

Strength Meets Flexibility

3D-printed scoliosis braces are not only lightweight but also remarkably durable. They can withstand over 10,000 open-and-close cycles without structural compromise — a crucial improvement for long-term wear.

Furthermore, digital design allows precise control of wall thickness and ventilation patterns, enabling practitioners to tailor the balance between support, flexibility, and breathability according to the patient’s clinical needs.

The MS01 SE: Powering the Future of Custom Orthotics

Building upon these advantages — lightweight design, superior strength, and complete customization — the PioCreat MS01 SE elevates professional orthotic fabrication to a new standard.

Equipped with a high-temperature nozzle (up to 400°C), the MS01 SE supports a broad spectrum of medical-grade polymers, ensuring each brace combines flexibility with structural integrity for long-term therapeutic use.

Its large build volume (500 × 500 × 650 mm) enables fabrication of various orthoses — from scoliosis braces to lower-limb supports — fulfilling diverse clinical requirements.

The fully enclosed thermal chamber ensures stable internal temperatures, optimizing print success rates and product consistency—both critical for producing precise medical devices. Additionally, its material-break detection system automatically pauses and resumes printing when materials are replenished, enabling uninterrupted workflow and allowing clinicians to focus on patient care.

A Smarter Future for Scoliosis Care

3D printing is not merely improving how scoliosis orthoses are manufactured — it is redefining clinical standards.

By merging digital precision, patient-specific customization, and advanced material science, technologies like the PioCreat MS01 SE are empowering clinicians to deliver superior comfort, improved correction, and enhanced quality of life for patients worldwide.